Vibration reduction connecting device for flanges based on particle damping

A vibration connection and damping technology, applied in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of vibration diffusion, difficult vibration reduction treatment, and the installation stability of the liquid outlet pipe does not meet the design requirements. , to achieve the effect of increasing the distribution rate and improving the vibration reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

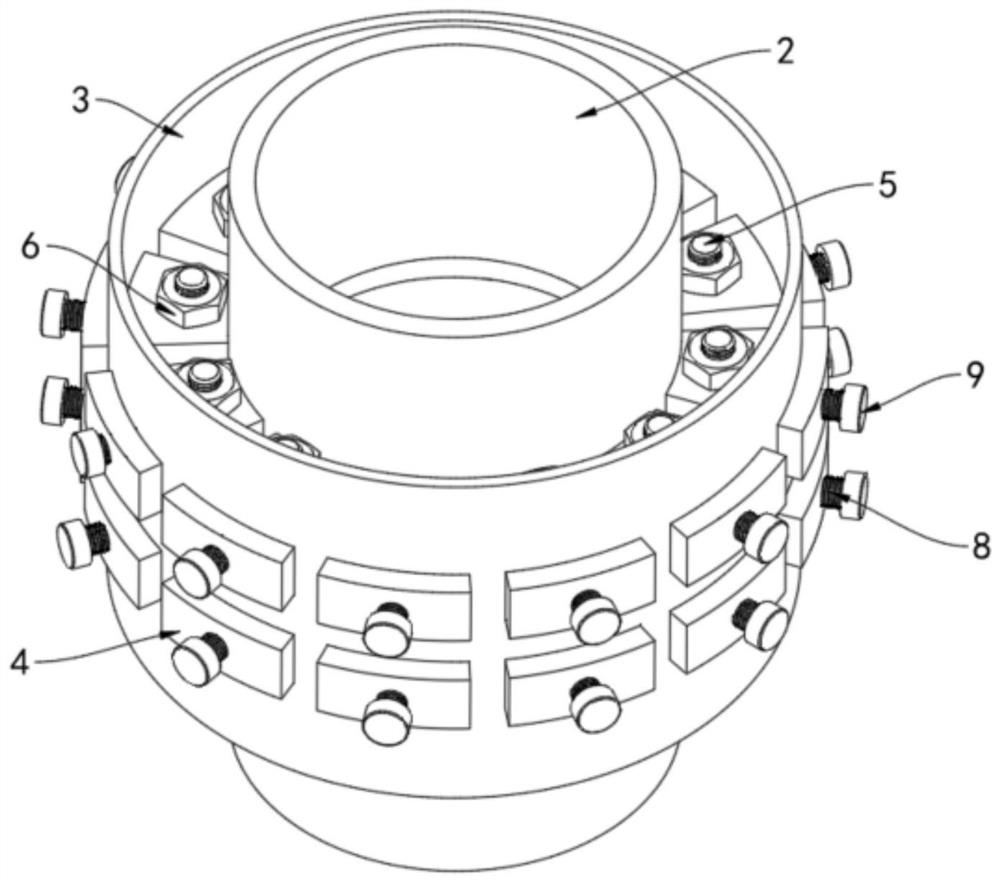

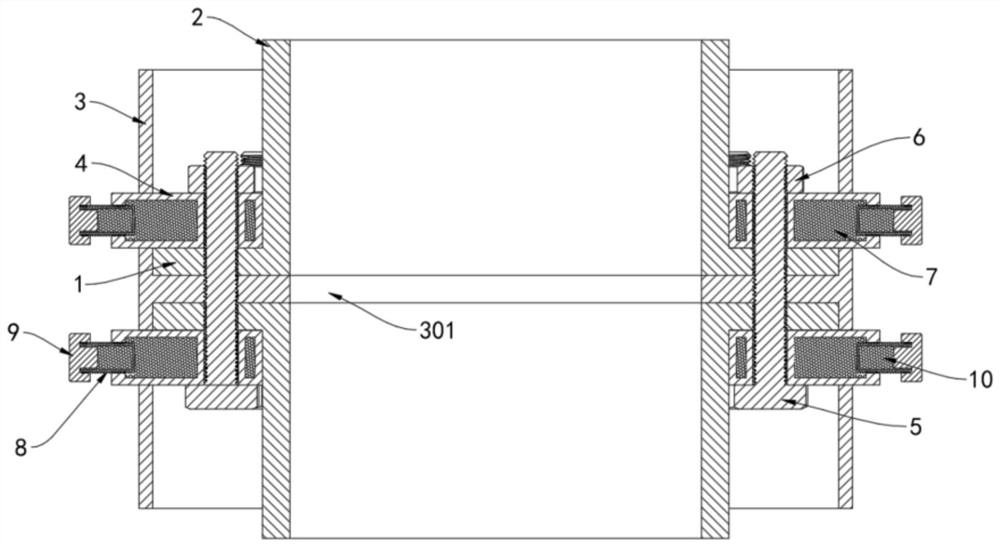

[0039] refer to Figure 1-6 , a vibration-damping connection device for flanges based on particle damping, including

[0040] A set of connecting flanges 1 are fixedly connected to the ends of corresponding workpieces 2;

[0041]The fixed pipe fitting 3 is sleeved on the outside of the set of connecting flanges 1, and the middle part of the inner side wall of the fixed pipe fitting 3 is fixed inwardly with a fixed gasket 301 arranged between the set of connecting flanges 1 , the fixed gasket 301 is respectively provided with corresponding first through holes 3011 at positions corresponding to the flange holes of the connecting flange 1, and the fixed pipe fitting 3 is located on both sides of the fixed gasket 301 A plurality of fixing grooves 302 corresponding to the flange holes of the connecting flange 1 are respectively provided;

[0042] A plurality of fixed boxes 4 are detachably installed in the fixed groove 302 respectively, and the inner ends of the fixed boxes 4 are...

Embodiment 2

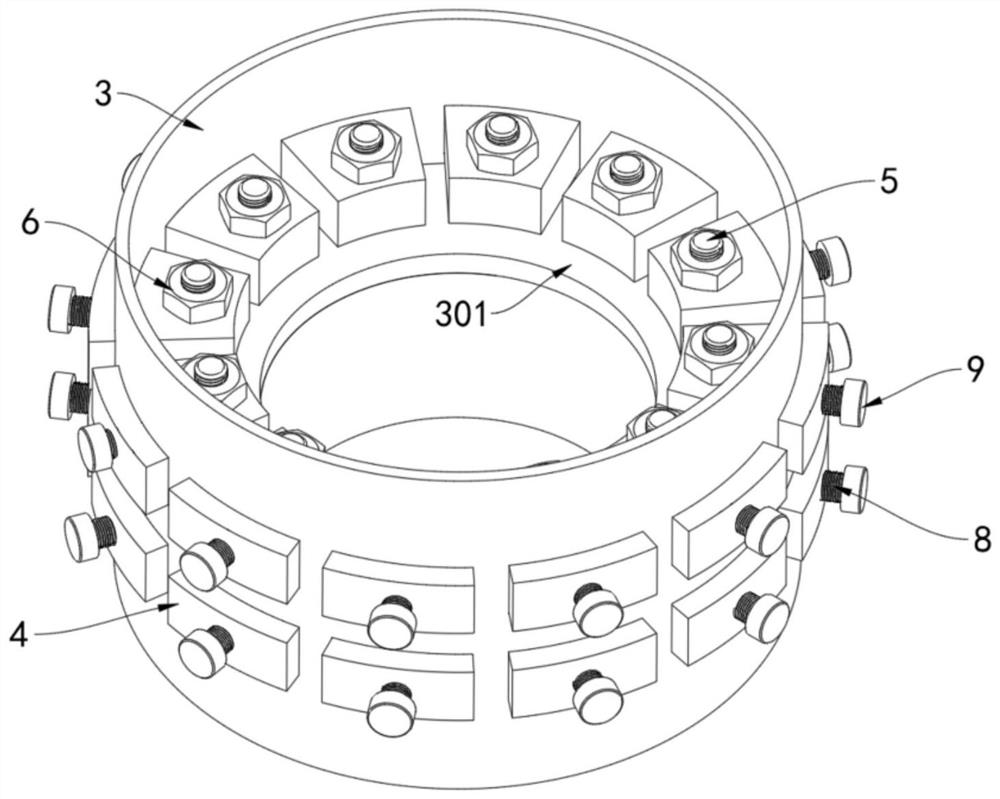

[0056] refer to Figure 7-8 The difference between this embodiment and Embodiment 1 is that the workpiece 2 is a column, and the connecting flanges 1 are respectively affixed to the outer side walls of the ends of the workpiece 2, and the fixing gasket 301 is arranged to be in contact with the The end of the workpiece 2 and the sheet that is compatible with the connecting flange 1.

[0057] It should be pointed out that the realization principle and the technical effect produced by this embodiment are the same as those of the first embodiment. For the sake of brief description, for the parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com