Base strip, extrusion hose composed of base strips and tool for producing extrusion hose

A technology for base strips and hoses, applied in the field of hoses, can solve problems such as generating loud noise and achieve the effect of reducing howling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

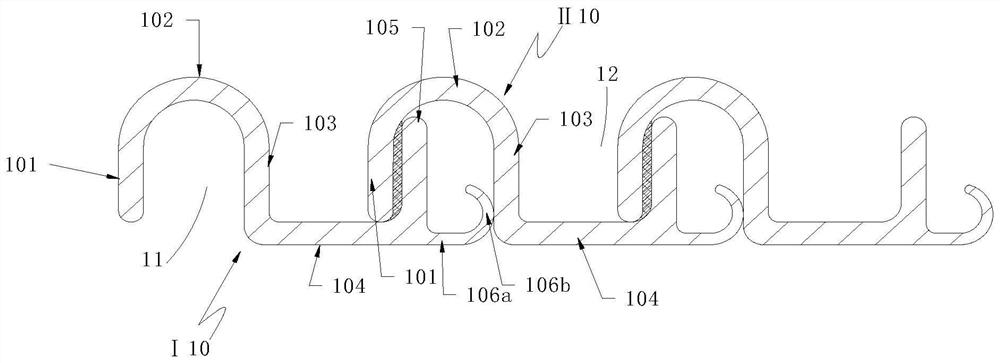

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

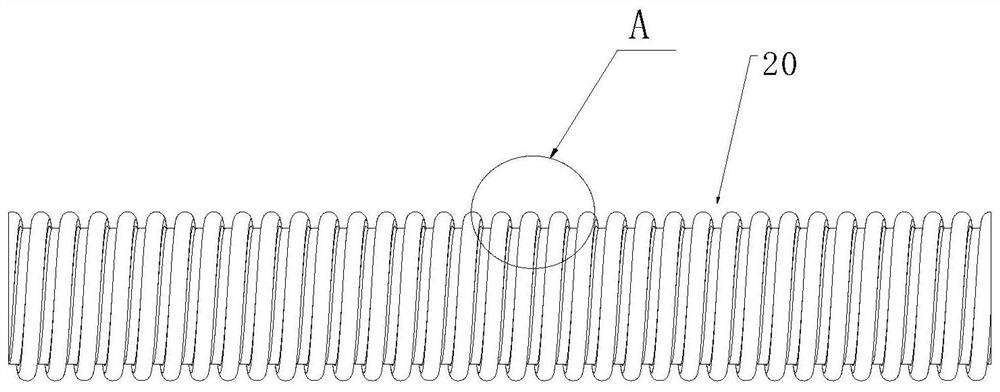

[0026] In order to make the extruded hose have better extensibility, the extruded hose is usually made of elastic material. To connect, by designing the base bar as a structure with telescopic ability, the extruded hose will be composed of multiple telescopic units with telescopic ability.

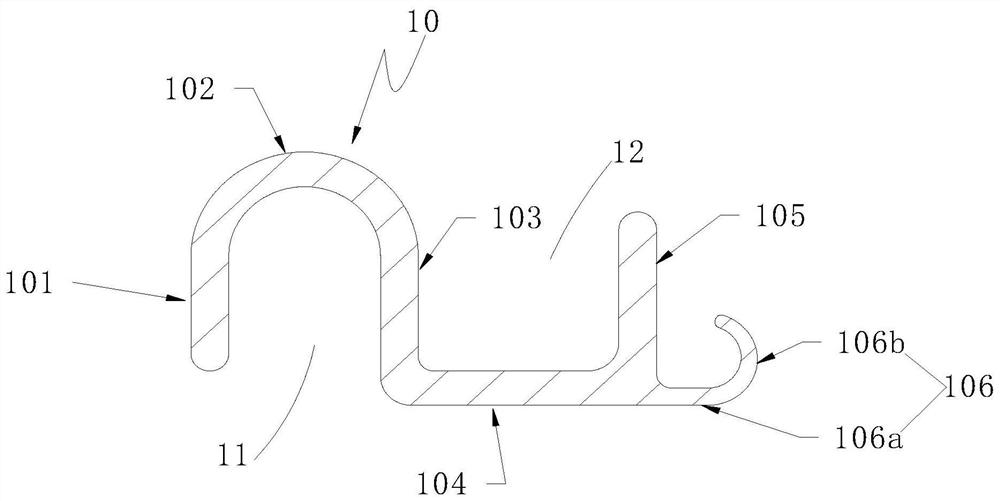

[0027] refer to image 3 , a base strip, including a first vertical portion 101, an arc portion 102, a second vertical portion 103, a first horizontal portion 104, and a third vertical portion 105 connected in sequence; the base strip is a strip-like structure as a whole, The end-to-end connection of the base bars can be surrounded into a ring, and then a plurality of base bars can form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com