Embedded part detection method and system

A detection method and detection system technology, applied in computer parts, image data processing, instruments, etc., can solve the problems of inaccurate, time-consuming and labor-consuming detection results, etc., to simplify the operation process, save detection time, and achieve accurate detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

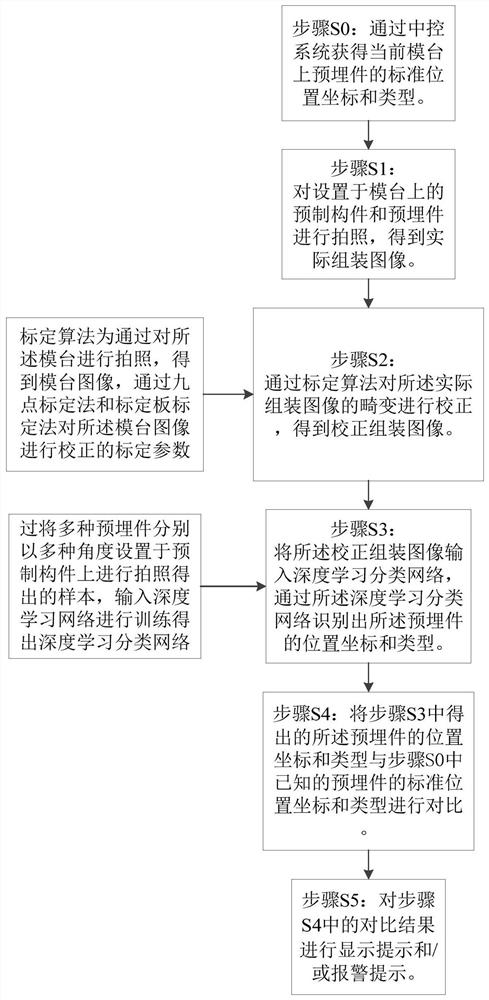

[0043] Such as figure 1 A specific implementation of the shown embedded part detection method includes the following steps:

[0044] Step S0: Obtain the standard position coordinates and type of embedded parts on the current mold table through the central control system;

[0045] Among them, the standard position coordinates and types of embedded parts are obtained through the central control system, which automatically extracts the standard position coordinates and types of embedded parts from the database files assembled by prefabricated components and embedded parts, and saves them in the central control system It is more convenient and accurate without manual input.

[0046] Step S1: Take pictures of the prefabricated components and embedded parts set on the mold table to obtain actual assembly images;

[0047] Among them, by setting the camera to take pictures of the prefabricated components and embedded parts, the camera can be selected according to different precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com