Method and device capable of eliminating glare on surfaces of high-reflection fruits and vegetables

A reflective fruit and vegetable and glare technology, applied in the field of optical detection, can solve the problems of unfavorable algorithm recognition, misjudgment of feature extraction, and affecting the accuracy of algorithm recognition, so as to facilitate the identification of surface features, improve the accuracy of feature recognition, and eliminate the problem of glare Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

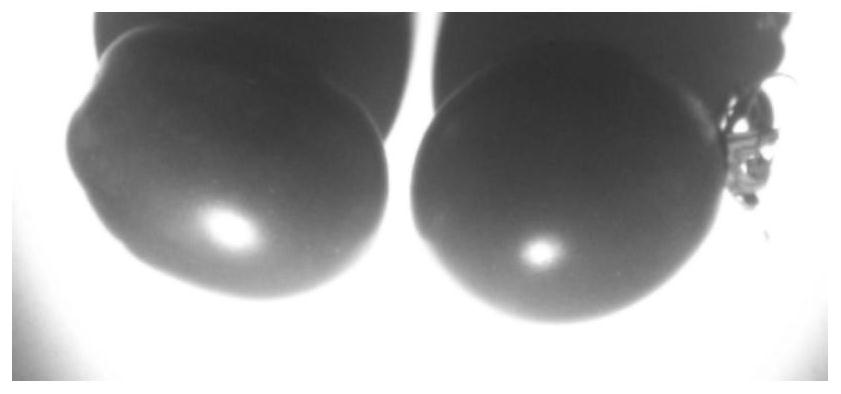

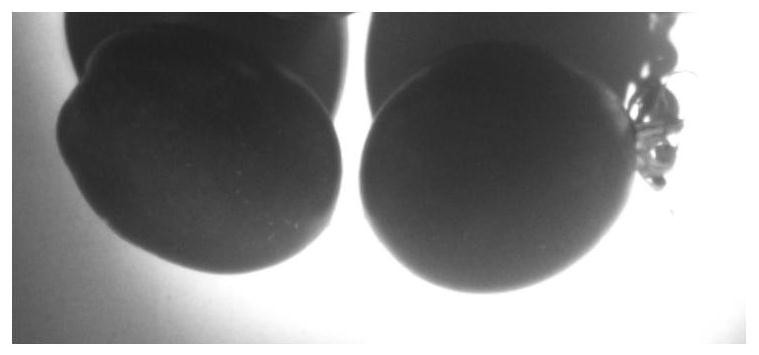

Image

Examples

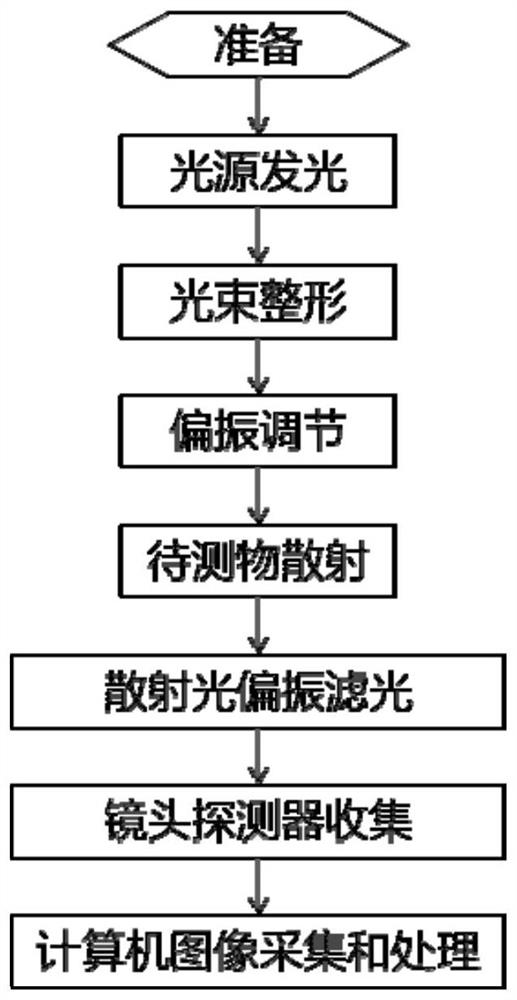

Embodiment 1

[0056] See Image 6 As shown, the background color of the fruit and vegetable transmission device 104 is preferably complementary to the color of the fruit and vegetable to be tested 105. Taking red cherry tomatoes as an example, the background color of the fruit and vegetable transmission device is preferably blue-cyan; the light source 101 used is preferably an LED white light surface light source, and the LED surface light source is composed of It consists of a driving circuit, an LED package chip array and a light guide plate 102. The function of the light guide plate is to make the illumination more uniform, and the LED light emission belongs to spontaneous radiation, which is non-polarized light; the first polarization adjustment module is the first linear polarizer 103, the working wavelength is 400- 760nm, 400-700nm can also be selected, and the transmission extinction ratio of the first linear polarizer is required to be greater than 100, and more preferably, the trans...

Embodiment 2

[0073] In Example 1, it can be seen from Equation (4) that under the premise of considering other losses, the first polarizer causes more than 50% of the light emitted by the LED chip to not participate in lighting, resulting in energy waste, so in Example 2 A method of imaging using line laser + line scan camera scanning is proposed, which is beneficial to improve the energy utilization rate of the light source, such as Figure 7 As shown, compared with the symmetrically placed LED surface light source in Embodiment 1, in Embodiment 2, the light source is replaced by a laser light source (laser beam combining module 201 ), which includes three laser beams, and the wavelength ranges of the three laser beams can be selected to be red, respectively. Light: 615-620nm, green light: 530-540nm, blue light: 460-470nm. Further, all three laser beams are required to be linearly polarized light. The energy ratio is red light: green light: blue light = 6:3:1, and it is further required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com