Method for producing composition for regenerating cartilage using freeze-dried hyaline cartilage powder, composition for regenerating cartilage produced using same, method for producing scaffold for regenerating patient-specific cartilage using composition for regenerating cartilage, and scaffold for regenerating patient-specific cartilage

A hyaline cartilage, patient-customized technology, used in the production of a cartilage regeneration composition using freeze-dried hyaline cartilage powder, the use of the produced cartilage regeneration composition, and the use of the cartilage regeneration composition to produce patient-customized cartilage regeneration scaffolds and In the field of cartilage regeneration scaffolds customized for patients, it can solve the problems of easy destruction of cartilage and difficult distribution and transplantation of cells, so as to achieve the effect of promoting cartilage regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] [Example 1] - the preparation of freeze-dried hyaline cartilage powder

[0090] After the obtained hyaline cartilage tissue was sliced, it was freeze-dried at a pressure of about 5 bar and a temperature of about -80° C. for about 12 hours in a near-vacuum atmosphere, and pulverized using a ball mill.

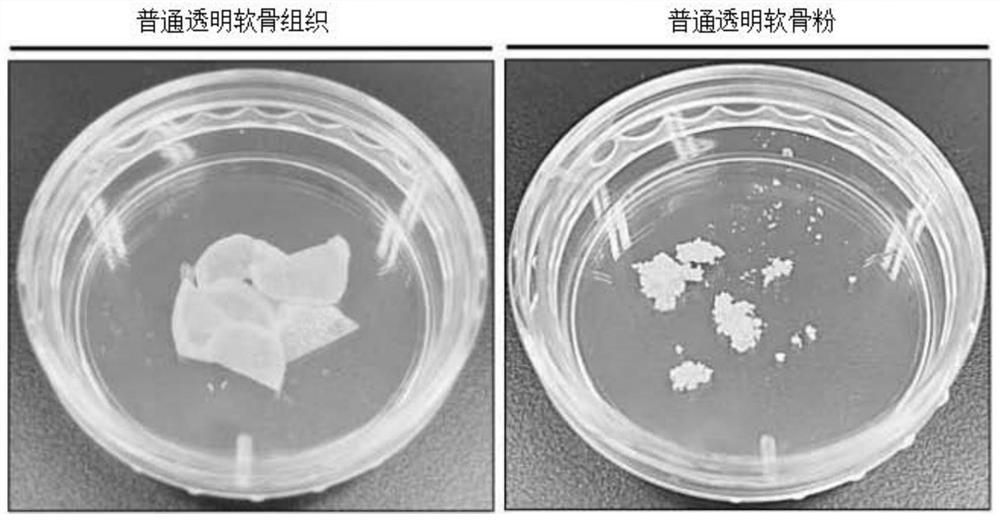

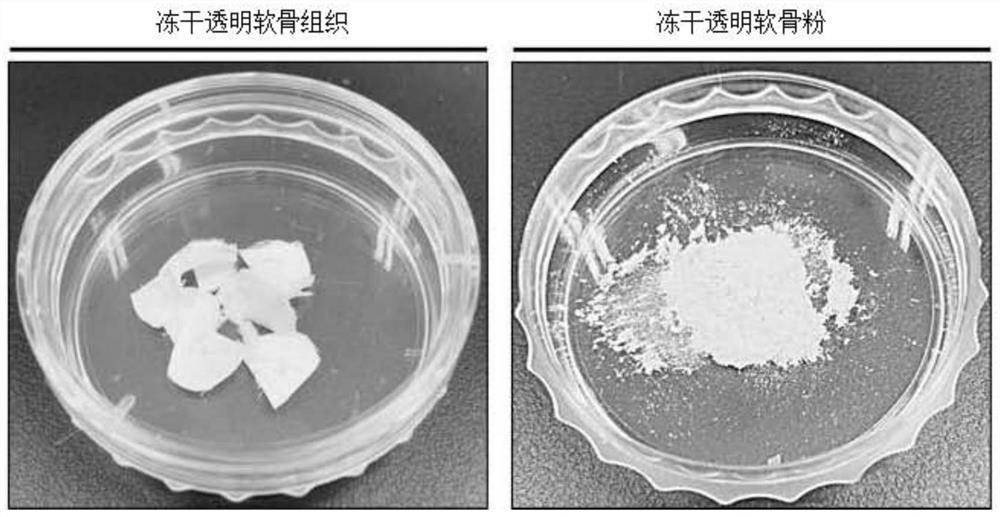

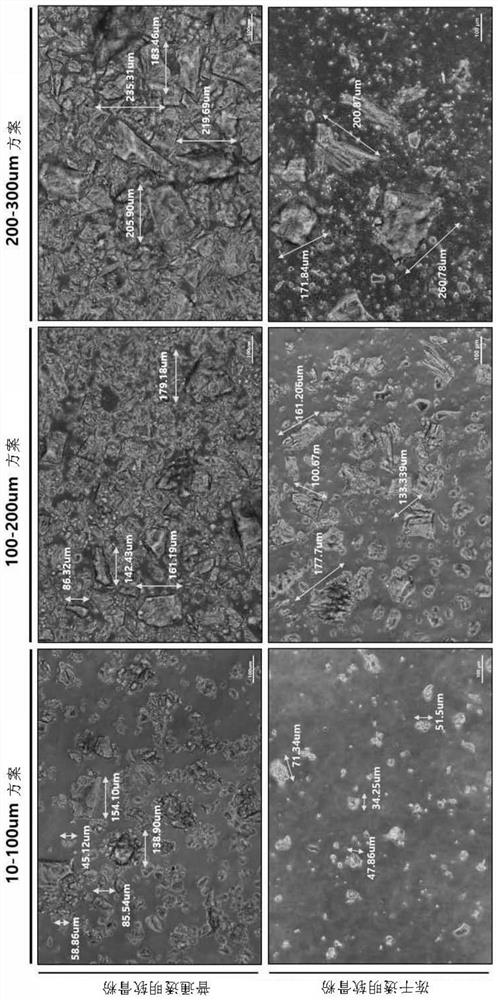

[0091] figure 2 is a set of images showing the freeze-dried hyaline cartilage tissue and its pulverization results according to Example 1. refer to figure 2 , different from figure 1 , it can be confirmed that hyaline cartilage powder is micronized into very fine particles without agglomeration.

[0092] That is, there may be problems in that the hyaline cartilage powder prepared as in Comparative Example 1 requires a separate dispersion process due to agglomeration and may clog a printer nozzle. In addition, the hyaline cartilage powder prepared as in Comparative Example 1 needs to be frozen at about -20°C, which is inconvenient. On the other hand, the freeze-drie...

experiment example 1

[0094] [Experimental Example 1]——Biocompatibility experiment of freeze-dried hyaline cartilage powder

[0095] To confirm the biocompatibility and regenerative capacity of the hyaline cartilage powder prepared as in Example 1, it was observed by hematoxylin and eosin (H&E) staining after injection into the dermis of laboratory mice, 4 weeks and 12 weeks later. Cytocompatibility results of freeze-dried hyaline cartilage powder.

[0096] Figure 4 The results after 4 weeks and 12 weeks according to Experimental Example 1 are shown. Specifically, refer to Figure 4 , After 4 weeks, it could be confirmed that the cells were concentrated around the implanted freeze-dried hyaline cartilage powder, and after 12 weeks, the cells were concentrated around the new tissue formed by the freeze-dried hyaline cartilage powder. Therefore, it could be confirmed that although the hyaline cartilage was freeze-dried, there were no side effects such as inflammation or reduction in tissue regene...

experiment example 2

[0097] [Experimental Example 2] - Animal experiment for confirmation of cartilage regeneration (in vivo experiment)

[0098] Autologous adipose tissue is obtained as follows: 70 to 150 mL of aspirate is taken from the abdomen of a laboratory beagle dog using liposuction under anesthesia, the aspirate is allowed to stand for about 5 minutes, and then the saline and the adipose tissue extracted with it are removed. sediment of blood.

[0099] Subsequently, the syringe containing the subject's fat and the fresh syringe were installed in the two-way inlet of the connector with a stainless steel syringe filter (Adnizer, SKT-AN-2400, BSL) with a pore size of 2.4 mm, and the fat was removed by piston movement. The fibers are removed from the autologous adipose tissue by passing it through the filter two or three times.

[0100] Subsequently, the fiber-free fat was injected into a filter bag (adipose tissue processing device, Tiss'you) containing a PET filter with a pore size of 500 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com