Sewage filtering equipment for efficiently treating residues in industrial sewage

A technology for industrial sewage and filtration equipment, which is applied in water/sewage treatment equipment, filtration circuits, filtration separation, etc. It can solve the problems of ineffective removal of sewage garbage impurities, single filtration method, and insufficient filtration, etc., to achieve convenient cleaning, good effect, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

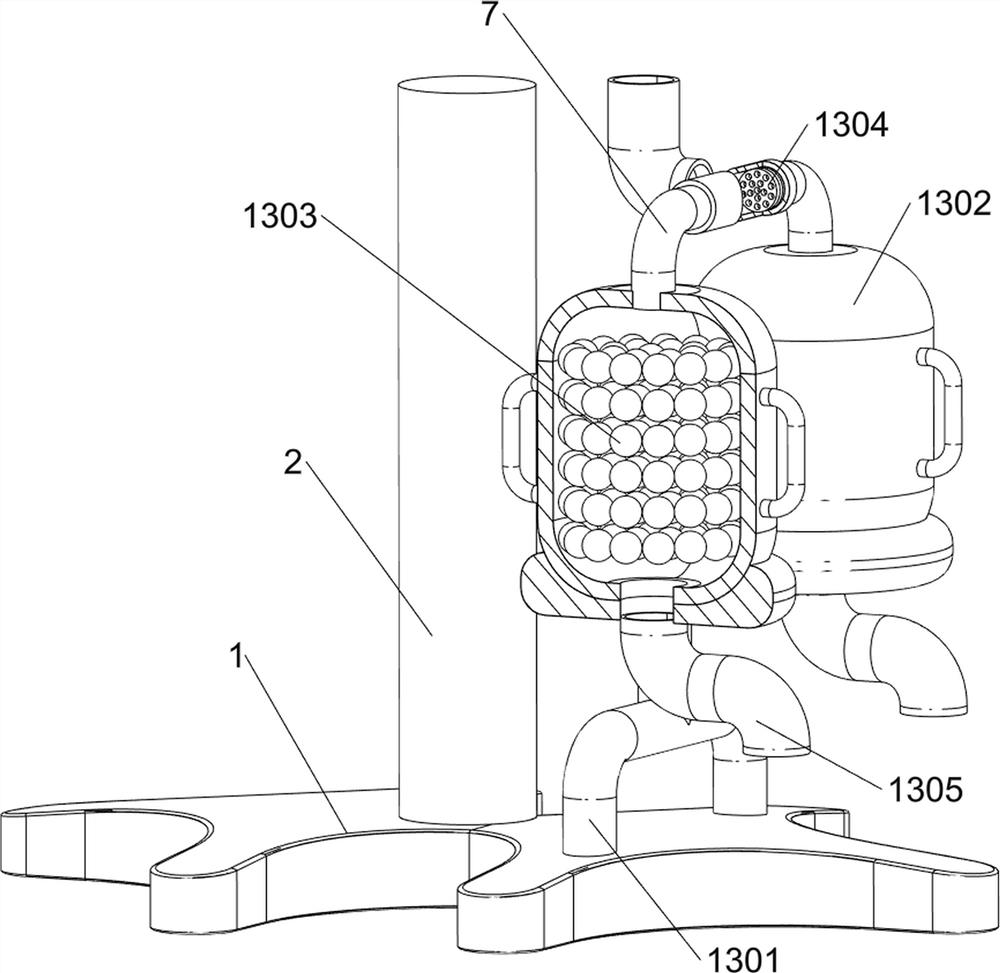

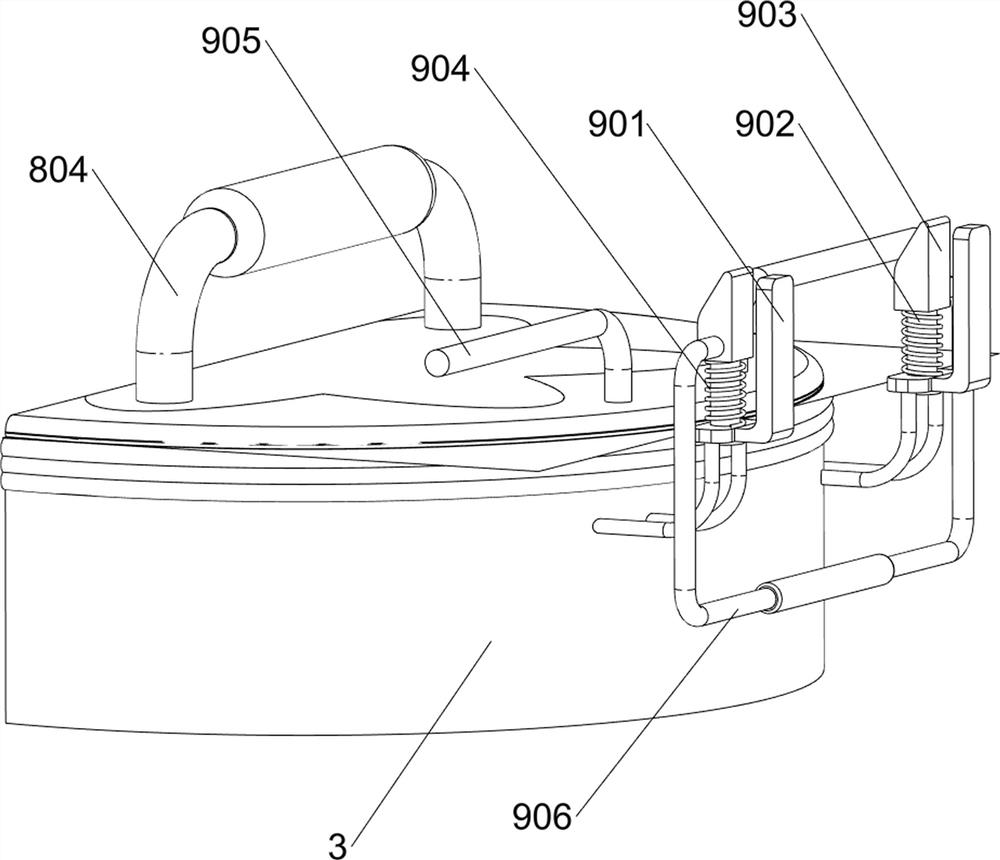

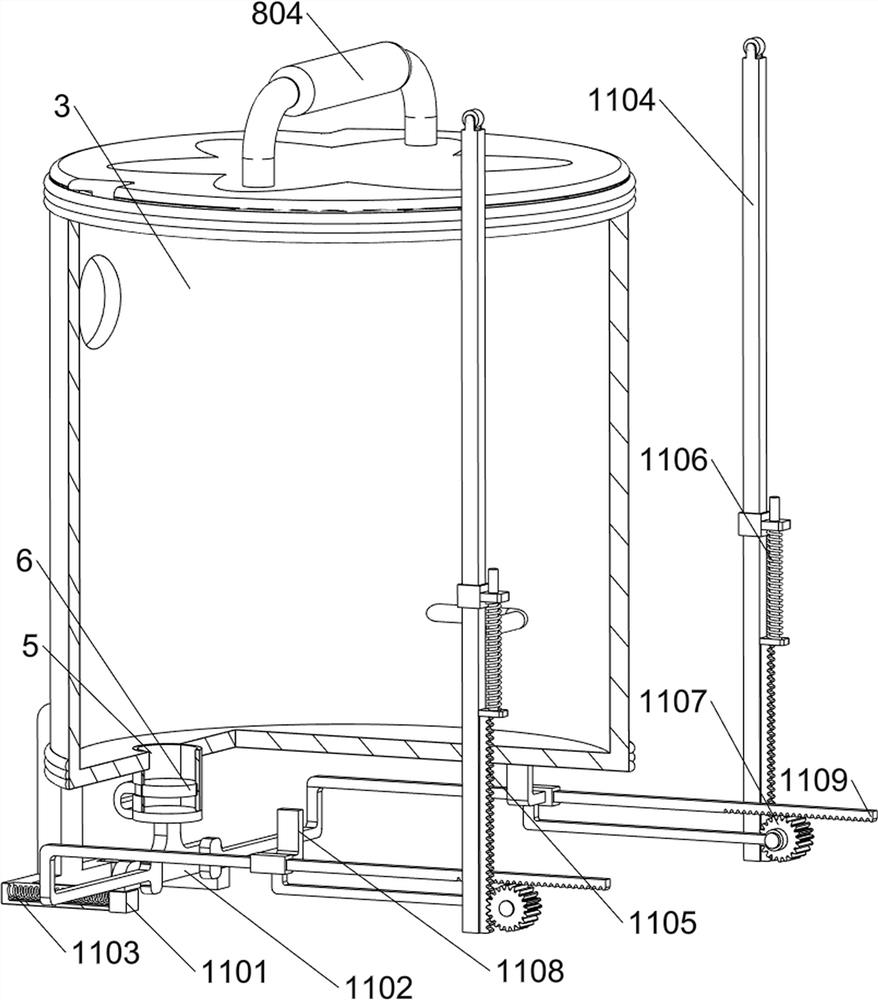

[0028] A sewage filter equipment for efficiently treating residues in industrial sewage, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a base 1, a first support rod 2, a water tank 3, a water inlet pipe 4, a sewage pipe 5, a valve 6, a drain pipe 7, an opening and closing assembly 8 and a clamping assembly 9, and the top of the base 1 is provided with a first Support rod 2, the top of the first support rod 2 is provided with a water tank 3, the upper left side of the water tank 3 is provided with a water inlet pipe 4, the left side of the bottom of the water tank 3 is provided with a sewage pipe 5, and the bottom of the sewage pipe 5 is slidingly provided with a valve 6, and the water tank 3 The right side of the bottom is provided with a drainage pipe 7, the top of the water tank 3 is provided with an opening and closing assembly 8, and the upper right side of the water tank 3 is provided with a clamping assembly 9.

[0029] The opening and cl...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a fishing assembly 10 is also included, and the fishing assembly 10 includes a filter screen 1001, a second connecting rod 1002, a second guide rod 1003, a second spring 1004, a chute 1005 and a limit block 1006, and the left side of the water tank 3 is Sliding type is provided with filter screen 1001, and the left side of water tank 3 bottom is symmetrically provided with second guide rod 1003 front and back, and the second guide rod 1003 is all slidingly provided with second connecting rod 1002, and second connecting rod 1002 all passes through cover 801 Connected with the filter screen 1001, a second spring 1004 is provided between the second connecting rod 1002 and the second guide rod 1003, and the second spring 1004 is set on the second guide rod 1003, and the outside of the first connecting rod 905 is provided with The chute 1005 and the right side of the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com