A kind of high color fastness environmental protection gray system reconstituted decorative veneer and its manufacturing process

A technology of high color fastness and reorganization of decoration, applied in the direction of manufacturing tools, joining of wooden veneers, wood processing utensils, etc., can solve the problem of low color fastness to light, etc. Dyeing time, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

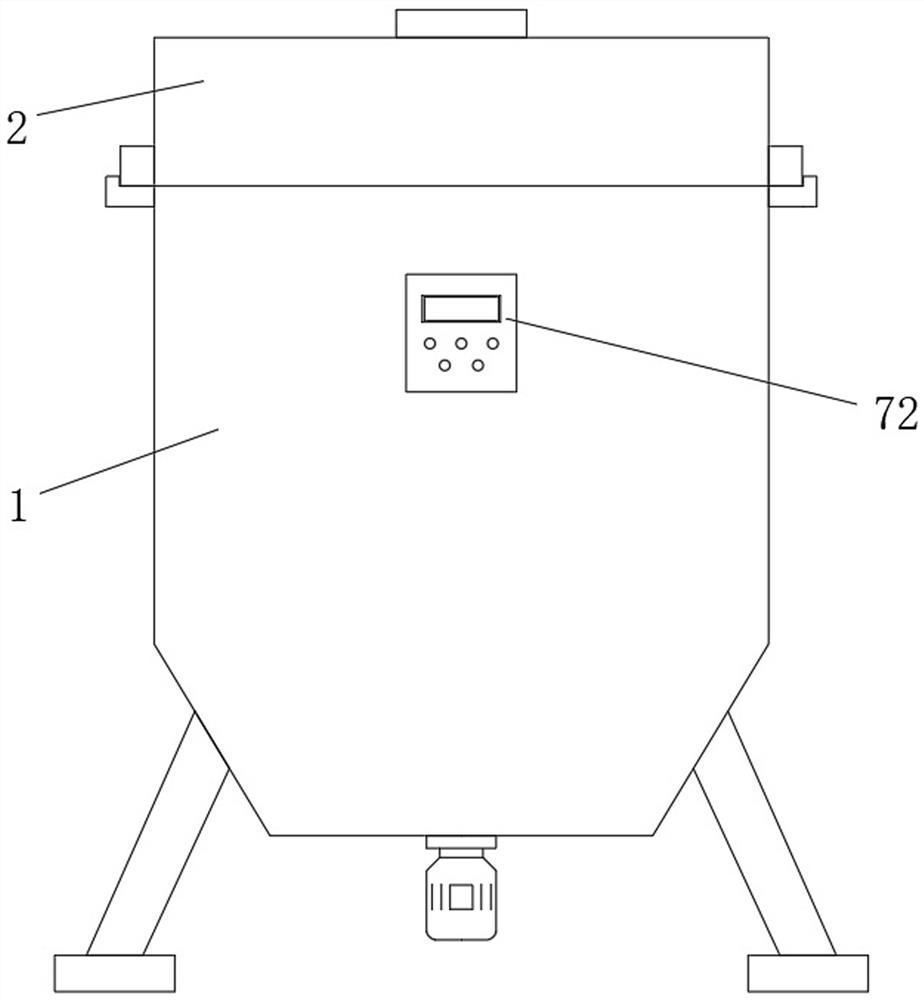

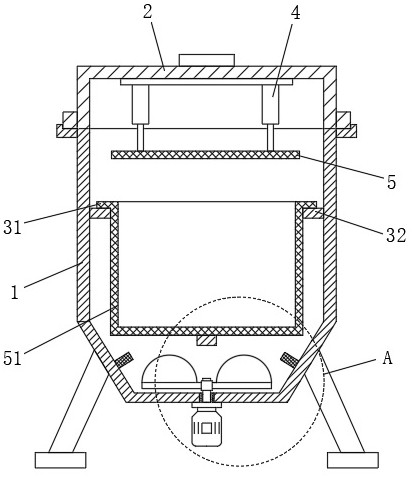

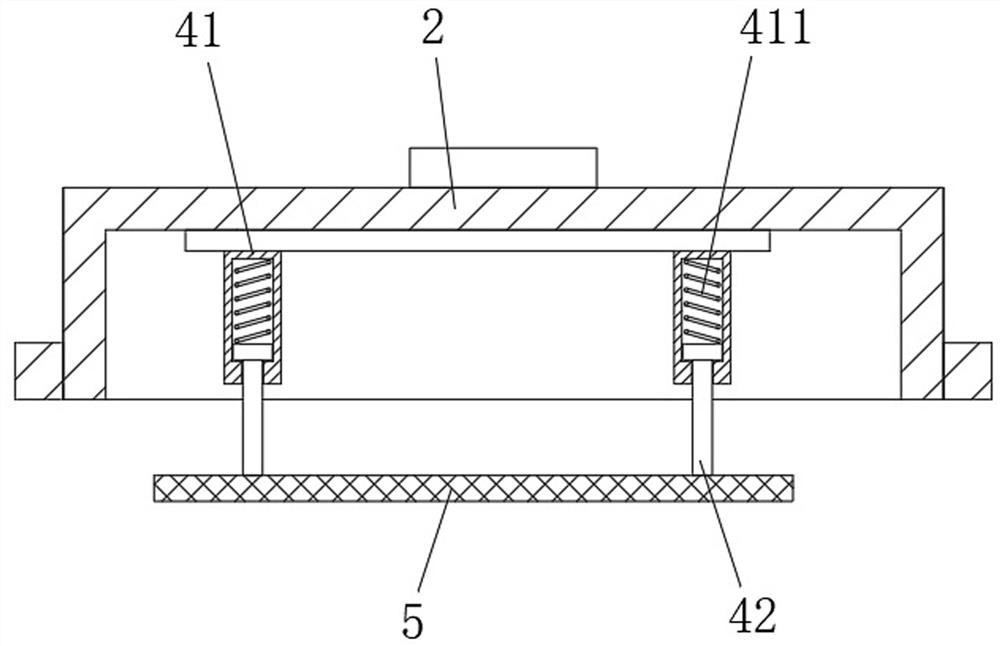

[0059] A manufacturing process of a high color fastness environment-friendly gray series reconstituted decorative veneer, comprising the following steps:

[0060] S1. Cut the logs into veneers by rotary cutting or slicing;

[0061] S2, carry out acetylation synergistic ultraviolet absorber pretreatment modification with the rotary cutting / slicing veneer obtained in step S1, and the concrete method comprises using acetic acid solvent to dilute acetic anhydride to obtain an acetic anhydride solution with a concentration of 20wt%, and then adding 4% (weight Proportion) After UV1130, the rotary cut / sliced veneer obtained in step S1 was soaked at 110°C for 20min;

[0062] S3, carry out pre-dyeing pretreatment on the acetylated-modified veneer obtained in step S2, and then preliminarily dry to a moisture content of 8%; fastness to dye liquor;

[0063] The water-based dyeing solution with high lightfastness and color fastness is gray-based chloro-s-triazine-based and vinylsulfone...

Embodiment 2

[0072] A manufacturing process of a high color fastness environment-friendly gray series reconstituted decorative veneer, comprising the following steps:

[0073] S1. Cut the logs into veneers by rotary cutting or slicing;

[0074] S2, carry out acetylation synergistic ultraviolet absorber pretreatment modification with the rotary cut / sliced veneer obtained in step S1, and the concrete method comprises using acetic acid solvent to dilute acetic anhydride to obtain an acetic anhydride solution with a concentration of 30wt%, and then adding 6% (wt%) Proportion) After UV1130, the rotary cut / sliced veneer obtained in step S1 was soaked at 130°C for 40min;

[0075] S3, carry out pre-dyeing pretreatment on the acetylated modified veneer obtained in step S2, and then preliminarily dry to a moisture content of 10%; then use a high color fastness wood dyeing device for dyeing, and the dyeing solution adopts water-based high light resistance color fastness to dye liquor;

[0076] ...

Embodiment 3

[0084] A manufacturing process of a high color fastness environment-friendly gray series reconstituted decorative veneer, comprising the following steps:

[0085] S1. Cut the logs into veneers by rotary cutting or slicing;

[0086] S2, carry out acetylation synergistic ultraviolet absorber pretreatment modification with the rotary cut / sliced veneer obtained in step S1, and the concrete method comprises using acetic acid solvent to dilute acetic anhydride to obtain an acetic anhydride solution with a concentration of 25wt%, and then adding 5% (wt%) Proportion) After UV1130, the rotary cut / sliced veneer obtained in step S1 was soaked at 120°C for 30min;

[0087] S3, carry out pre-dyeing pre-treatment to the acetylation-modified veneer obtained in step S2, and then preliminarily dry to a moisture content of 9%; then use a high color fastness wood dyeing device for dyeing, and the dye solution adopts water-based high light-fast color fastness to dye liquor;

[0088] The wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com