Discharging control method and device and mixing plant

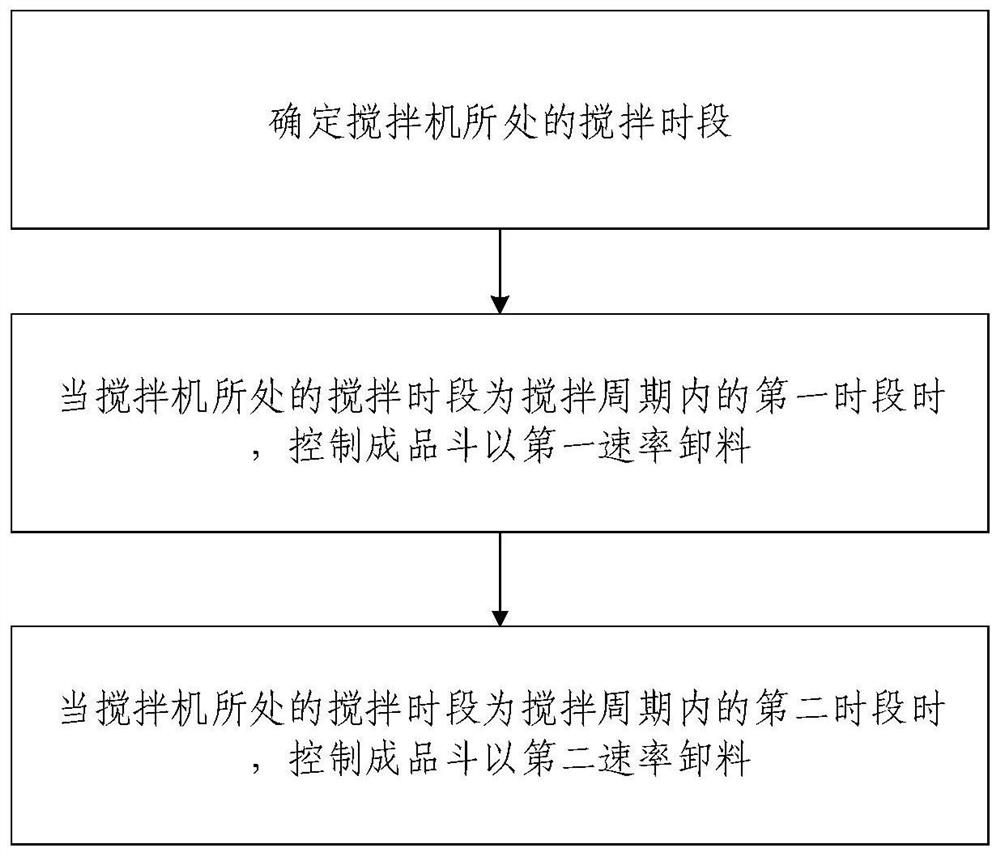

A control method and mixer technology, applied in the field of discharge control and mixing station, can solve the problems of high labor cost and low degree of automation for unloading finished product hoppers, and achieve the effect of facilitating production tact, reducing labor cost and controlling production takt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

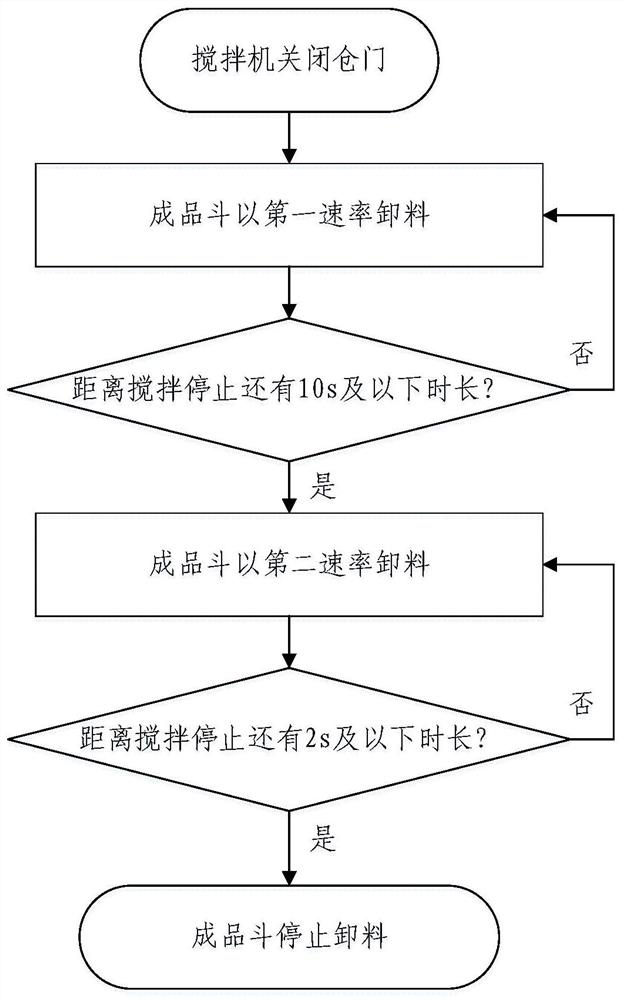

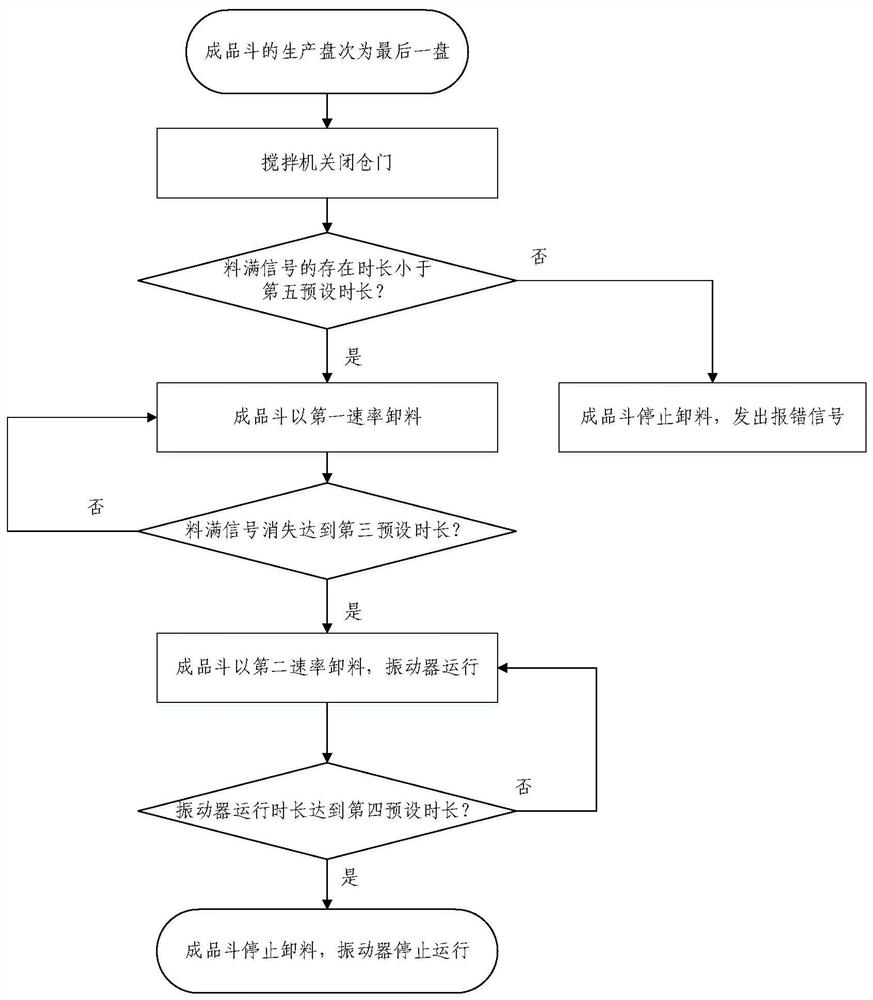

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objects, technical solutions, and advantages of the present invention, the technical solutions in the present invention will be apparent from the drawings of the present invention, and it will be described in connection with the drawings of the present invention. , Not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained without creative labor are not made in the premise of creative labor.

[0042] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are used to illustrate the invention, but not to limit the scope of the invention.

[0043] Moreover, the terms "first", "second", etc. are only used to describe purposes, and cannot be understood as an indication or implies relative importance or implicitting the number of techniques indicated. Thus, the features of "first", "second" are defined, and at least one of the features may be indicated or implicitly. In the description of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap