Servo press capable of conveniently adjusting bottom dead center

A servo press, dead center technology, applied in the field of presses, can solve the problems of decreased production accuracy and the shift of the bottom dead center of the servo press during service time, and achieves the effect of easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

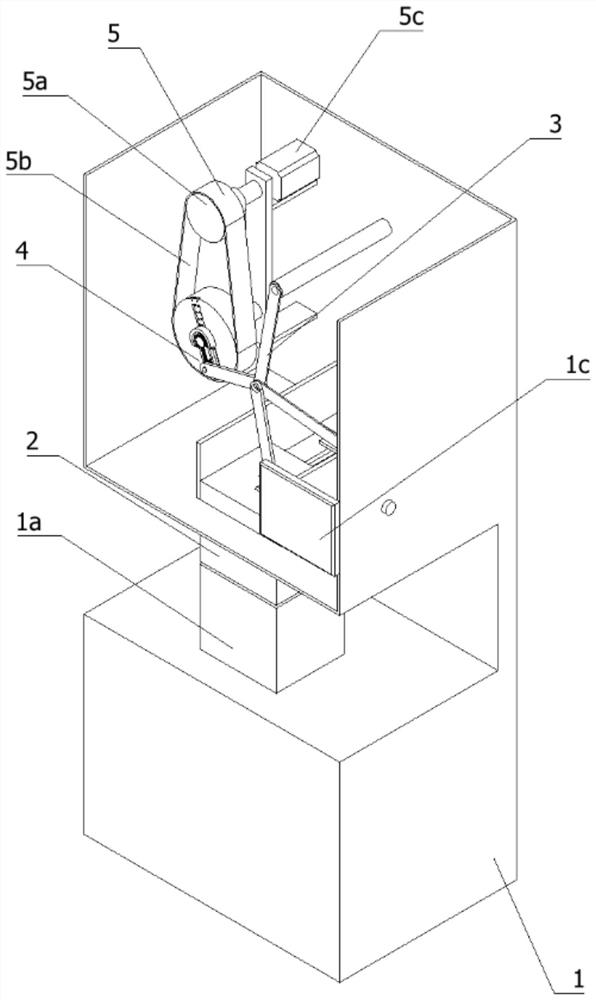

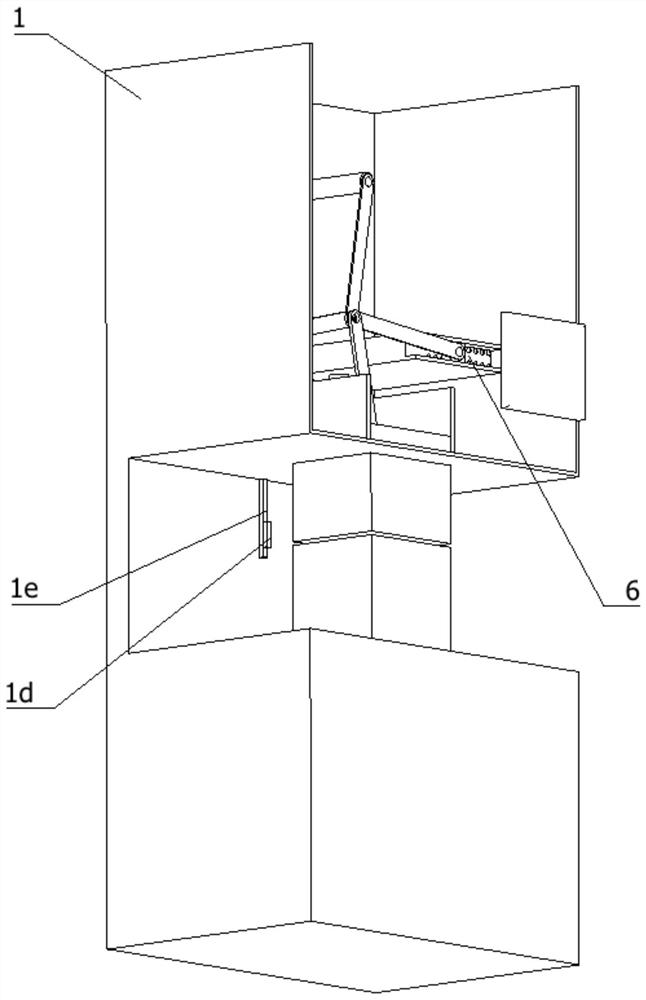

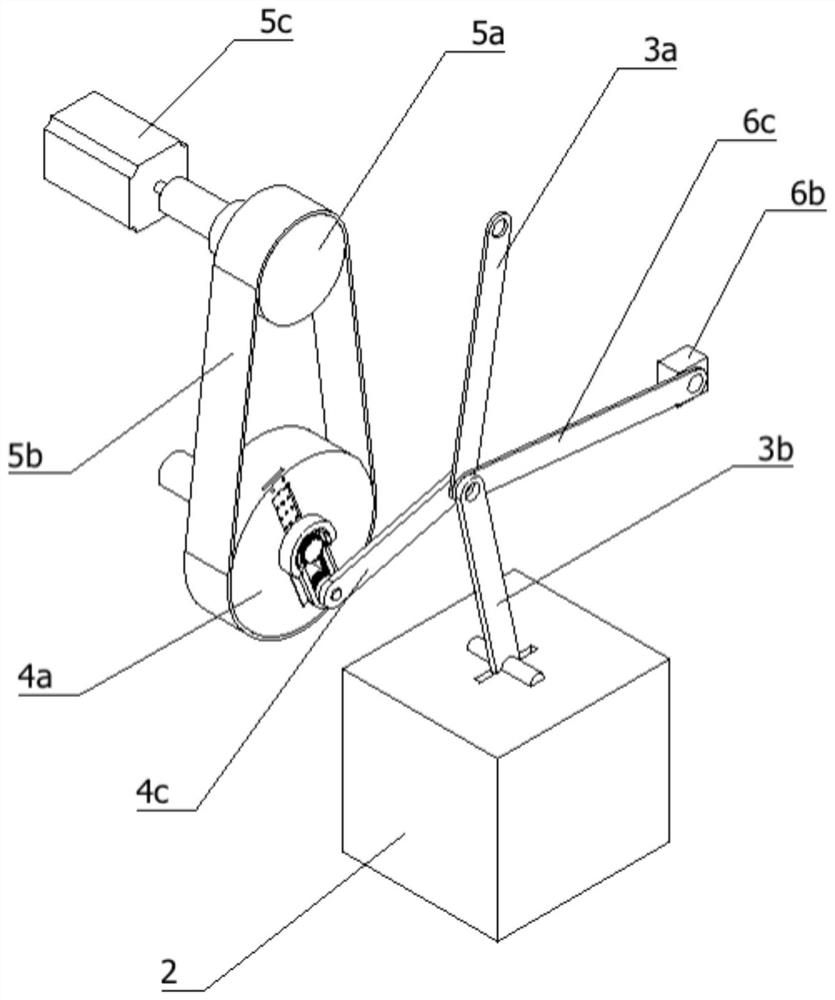

[0082] In order to solve the technical problem of how to make the bottom dead point of the servo press easy to adjust, such as Figure 1-6 As shown, the following technical solutions are provided:

[0083] A servo press for convenient adjustment of the bottom dead center, including:

[0084] Rack 1;

[0085] The lower pressing block 2, which is movably arranged on the frame 1 along the vertical direction;

[0086] A toggle mechanism 3, the toggle mechanism 3 is installed on the frame 1, the output end of the toggle mechanism 3 is connected to the lower pressing block 2, and the toggle mechanism 3 is used to drive the lower pressing block 2 to move;

[0087] Crank link mechanism 4, the crank link mechanis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap