One-way transmission middle assembly type double-layer rotating assembly

A one-way transmission and rotating component technology, applied in one-way clutches, rotating bearings, bearing components, etc., can solve the problems of difficult to complete production and assembly, cumbersome design process, etc., to improve efficiency, improve service life, and improve assembly. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

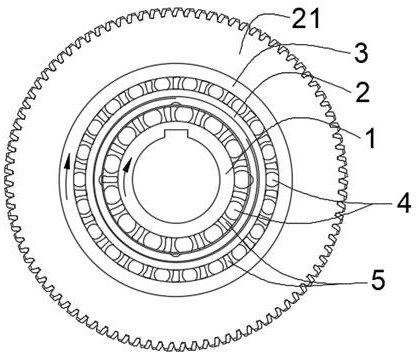

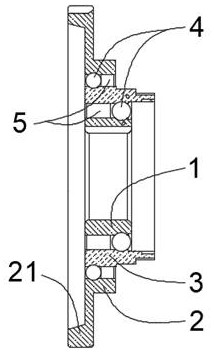

[0029] Such as figure 1 and figure 2 In the shown embodiment 1, the one-way transmission intermediate assembly type double-layer rotating assembly is an assembly assembly for assembly and integration in a manner similar to the use of bearings. It includes an annular coaxially assembled inner sleeve 1, an outer sleeve 2, and a middle sleeve 3. There are 4 rolling bodies installed between the inner sleeve 1, the outer sleeve 2 and the middle sleeve 3 respectively. In this embodiment, the rolling The piece 4 is a steel ball, and the inner wall of the outer jacket 2, the outer wall of the inner jacket 1 and the inner and outer walls of the middle jacket 3 are respectively designed with positioning grooves for accommodating corresponding steel balls. The inner wall of the inner sleeve 1, the outer wall of the outer sleeve 2, and the end of the middle sleeve 3 are respectively designed with assembly structures, and the assembly structures are designed according to specific usage c...

Embodiment 2

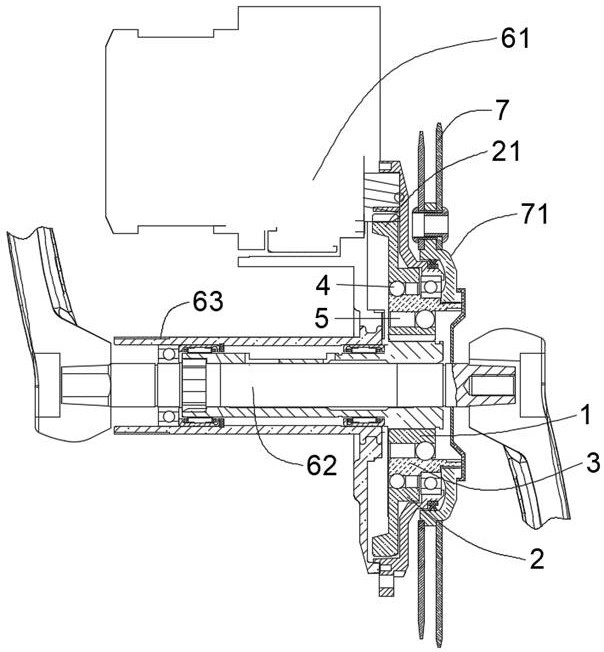

[0038] As shown in the picture Figure 4 , Figure 5 and Figure 6 As shown, the assembly also includes an inner sleeve 1a, an outer sleeve 2a, a middle sleeve 3a, a rolling element 4a, and a clutch 5a with the same structure. The inner sleeve 1a and the outer sleeve 2a are also respectively connected to the motor 61 and the pedal shaft. The above structure is the same as that of Embodiment 1, and will not be repeated here. A through hole corresponding to the threaded hole is designed on the connecting piece 71a, and the connecting piece 71a is fixed on the right side of the middle sleeve 2a by bolts. Specifically, the right end of the middle sleeve 3a is designed with a stepped shaft with a reduced outer diameter, the left side of the stepped shaft corresponds to a shoulder 31a, the through hole in the middle of the connecting piece 71a is a smooth round hole, and the connecting piece The through hole of the through hole is coaxially positioned and assembled with the stepp...

Embodiment 3

[0040] In this example, if Figure 7 and Figure 8 As shown, the inner wall of the inner sleeve 1b is processed with an inner keyway for assembly and connection, and the outer wall of the outer sleeve 2b is processed with an outer keyway for assembly and connection. In this way, the inner sleeve 1b and the outer sleeve 2b are respectively connected to the components to be assembled through the inner keyway and the outer keyway. The left and right sides of the inner sleeve 1b, the outer sleeve 2b and the middle sleeve 3b are flush, and the inner sleeve 1b, the outer sleeve 2b and the middle sleeve 3b are respectively equipped with parallel rolling elements 4b and clutch parts 5b. Evenly distributed threaded holes are processed on the end surface of the middle sleeve 3b, and the threaded holes are used to lock and connect the components to be assembled by bolts. In this embodiment, the overall structure of the component is more regular and compact, the manufacturing cost is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com