Intelligent cooling fire-resistant bus duct

A fire-resistant, busbar technology, applied in the field of busbars, can solve the problems of inability to extinguish fire, poor effect, poor practicability, etc., and achieve the effects of easy fire extinguishing, easy multiple use, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

[0025] The specific implementation of the present invention will be described in detail below with reference to specific embodiments.

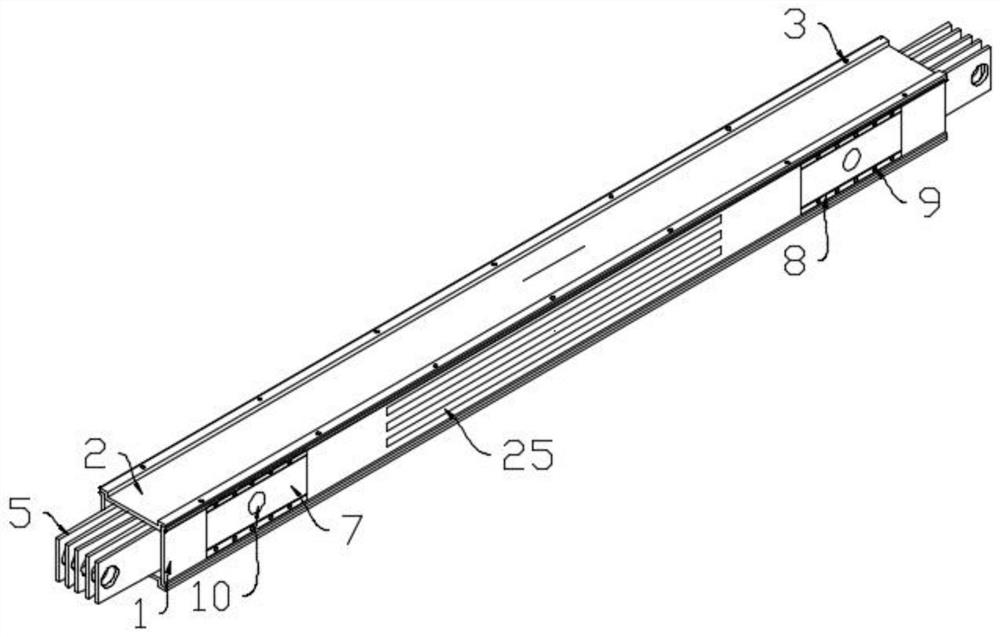

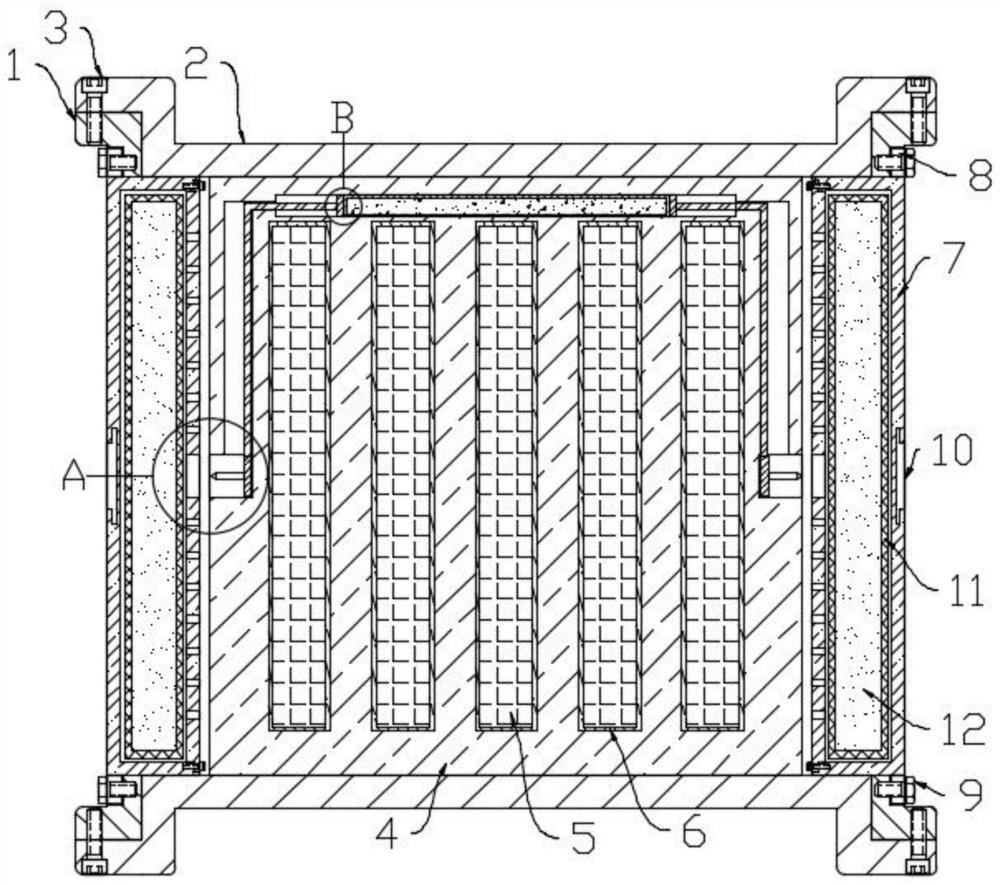

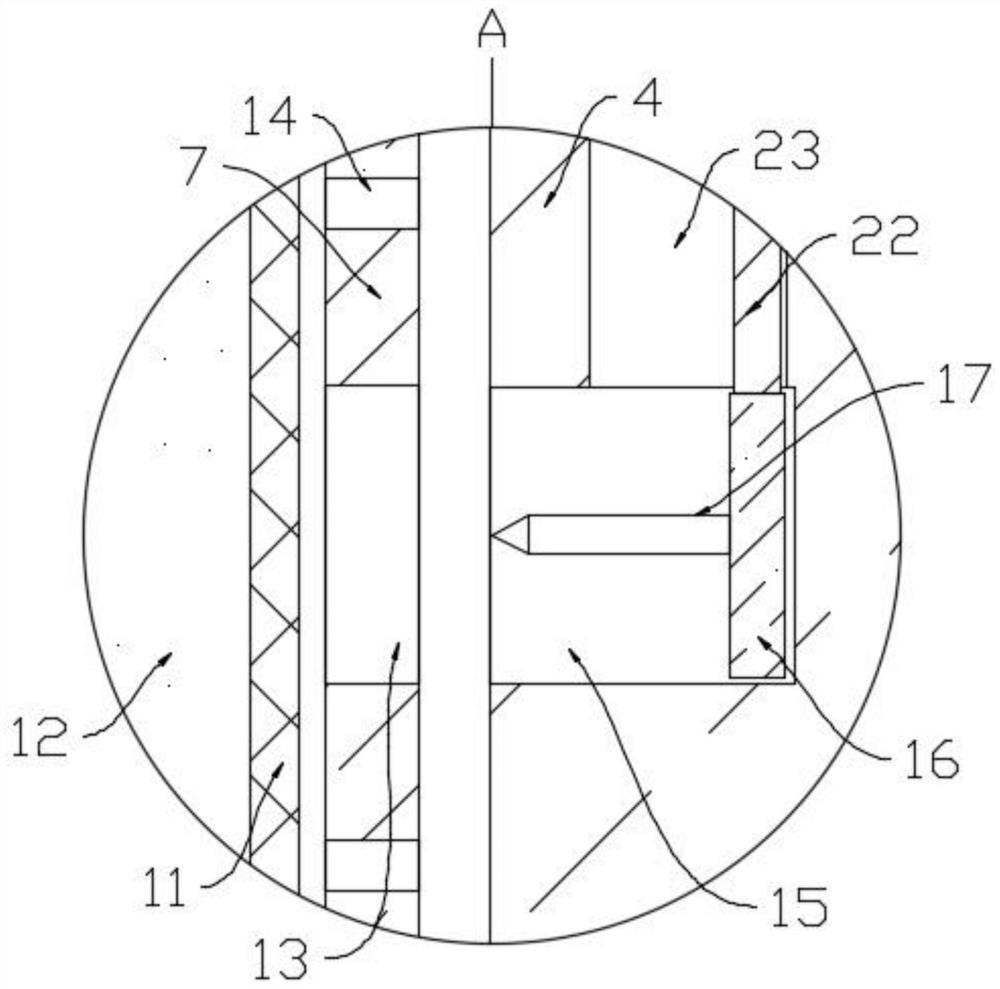

[0026] like figure 1 , 2 As shown in and 5, a structural diagram of an intelligent cooling refractory busway provided by an embodiment of the application, including a shell, two symmetrically arranged card boards 4 are fixedly connected in the shell, and a card board 4 is fixedly connected with a There are five busbars 5, and side boxes 7 are detachably connected to the two inner walls of the casing near the card board 4. The side box 7 is provided with a film body 11, the film body 11 is filled with cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com