Remote online monitoring system for hydrogen production device and implementation method of remote online monitoring system

A hydrogen production device and monitoring system technology, applied in the direction of selection device, master station device, electrical transmission signal system, etc., can solve problems such as potential safety hazards, easy to generate false alarms, and online monitoring system does not have the ability to review, to improve The effect of correct rate, avoiding misjudgment, improving work efficiency and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

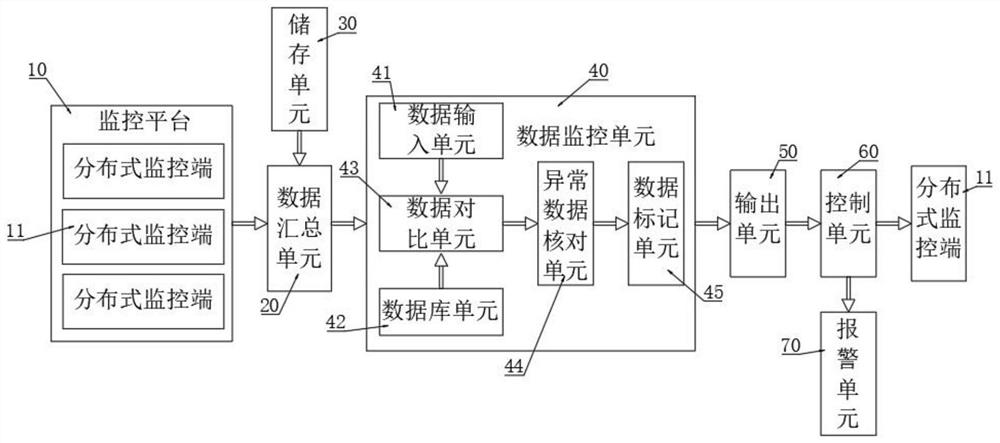

[0026] refer to figure 1 as well as figure 2 , a remote online monitoring system for a hydrogen production device described in this embodiment includes a monitoring platform 10, and the monitoring platform 10 includes several distributed monitoring terminals 11 installed in a distributed manner, that is, the distributed monitoring terminals 11 are installed At various positions in the hydrogen production chamber, it is used to obtain data related to hydrogen production such as temperature, concentration, and pressure;

[0027] The system also includes a data summarization unit 20, which is used to summarize the data collected by the monitoring platform 10 to establish a monitoring data pool;

[0028] The system also includes a data monitoring unit 40, which is used to find the abnormal part in the monitoring data pool, and after checking, mark the abnormal data and indicate the location where the abnormal data is generated in the hydrogen production chamber;

[0029] The sy...

Embodiment 2

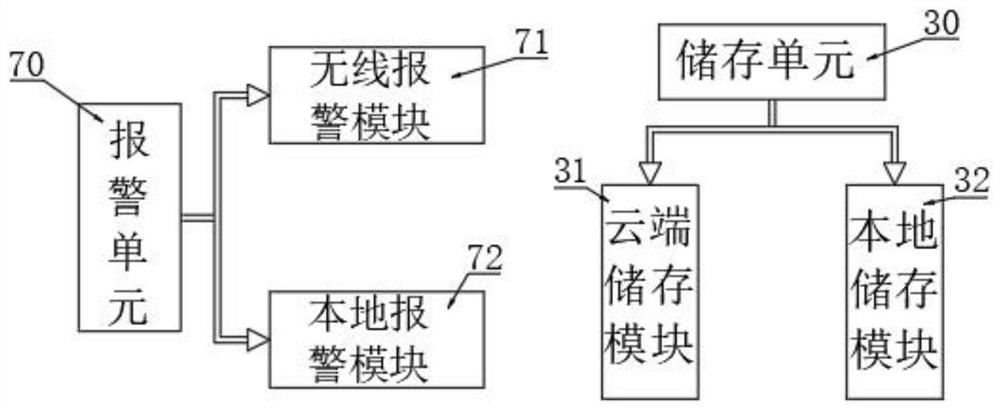

[0044] refer to figure 1 as well as figure 2 The remote on-line monitoring system of a hydrogen production device described in this embodiment is a further improvement made on Embodiment 1, and also includes a storage unit 30 for storing the monitoring data collected by the data collection unit 20, It is convenient for users to call and select at any time;

[0045]The storage unit 30 includes a cloud storage module 31 and a local storage module 32, the cloud storage module 31 is used to back up the local storage module 32; data loss can be avoided, and at the same time, because the data is online, it is also convenient for other users to call The cloud storage module 31 has online storage and sharing functions, and is used to store the monitoring data on the line, which is Huawei Cloud, Alibaba Cloud or similar clouds; the local storage module 32 has the function of local storage, and is used to store the monitoring data. Stored locally, it is a hard disk module.

Embodiment 3

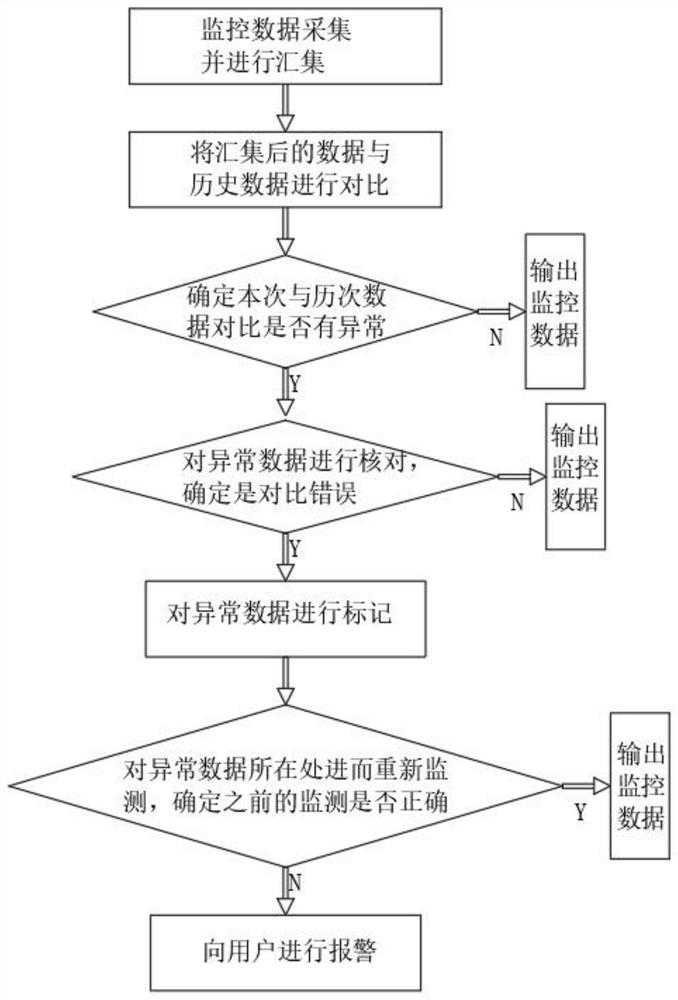

[0047] refer to figure 2 , a method for remote on-line monitoring of a hydrogen production device described in this embodiment, comprising the following steps,

[0048] S01. Collect and summarize the monitoring data in the hydrogen production chamber;

[0049] S02. Comparing the collected current data with the historical data, and outputting the current data when it is confirmed that there is no abnormal data;

[0050] S03. When the verification confirms that there is abnormal data in the current data, the verification is carried out to confirm whether there is a judgment error, and if the judgment is indeed wrong, output the current data;

[0051] S04. Marking the location of the source of the abnormal data, indicating the corresponding location;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com