Marine foam fire extinguishing tail end mixing device and fire extinguishing system

A foam fire extinguishing and mixing device technology, applied in fire rescue and other directions, can solve problems such as inability to achieve fire extinguishing effects, and achieve the effects of avoiding the continuous spread of fire, speeding up fire extinguishing, and improving fire extinguishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

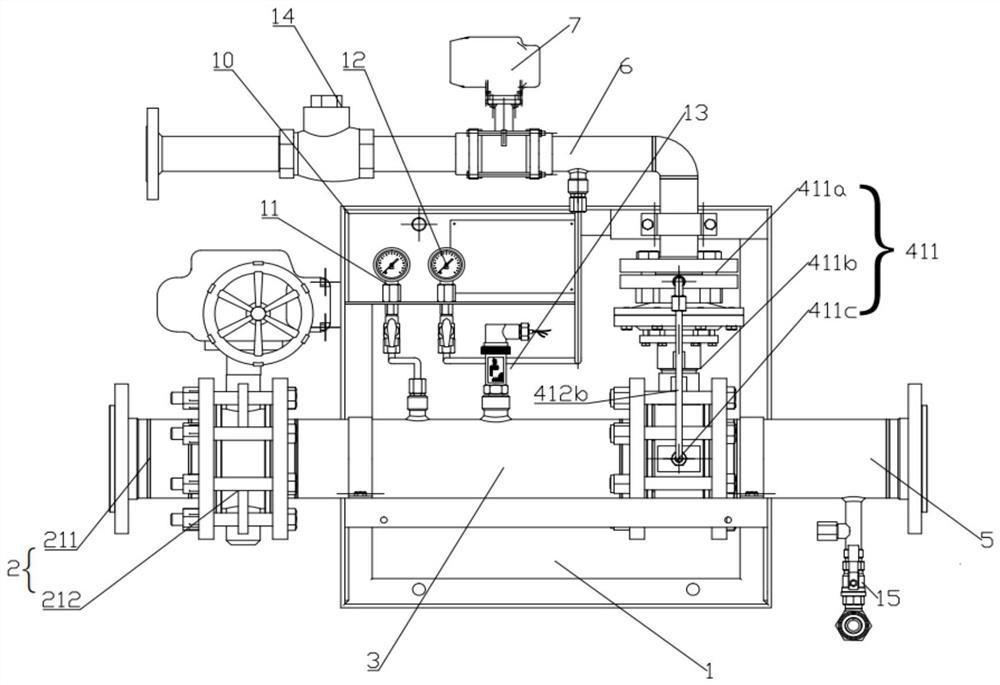

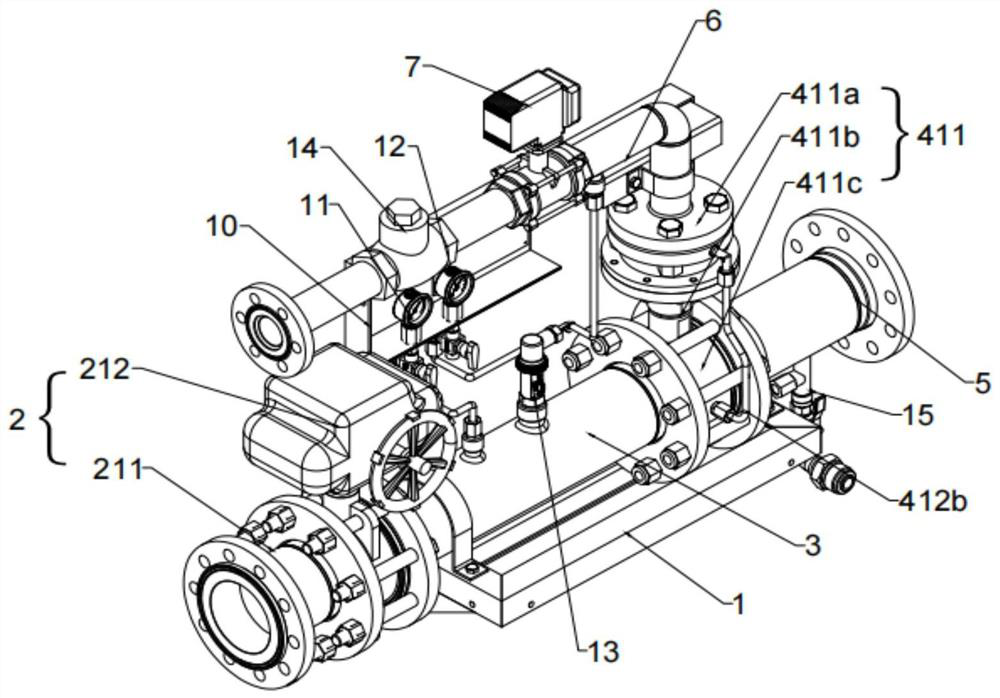

[0030] Such as Figure 1-5 As shown, a marine foam fire extinguishing terminal mixing device proposed by the present invention includes a base 1, and the top of the base 1 is sequentially provided with a fire-fighting water inlet device 2, a connecting pipe 3, a proportional mixer 4 and an outlet pipe 5 from left to right, One end of the connecting pipe 3 communicates with the fire water inlet device 2, the other end communicates with the proportional mixer 4, the proportional mixer 4 communicates with the outlet pipe 5, and the upper end of the proportional mixer 4 is connected with a foam inlet pipe 6, and the foam inlet pipe 6 is set There is an electric ball valve 7, and the electric ball valve 7 is used to start or close the inflow of foam liquid;

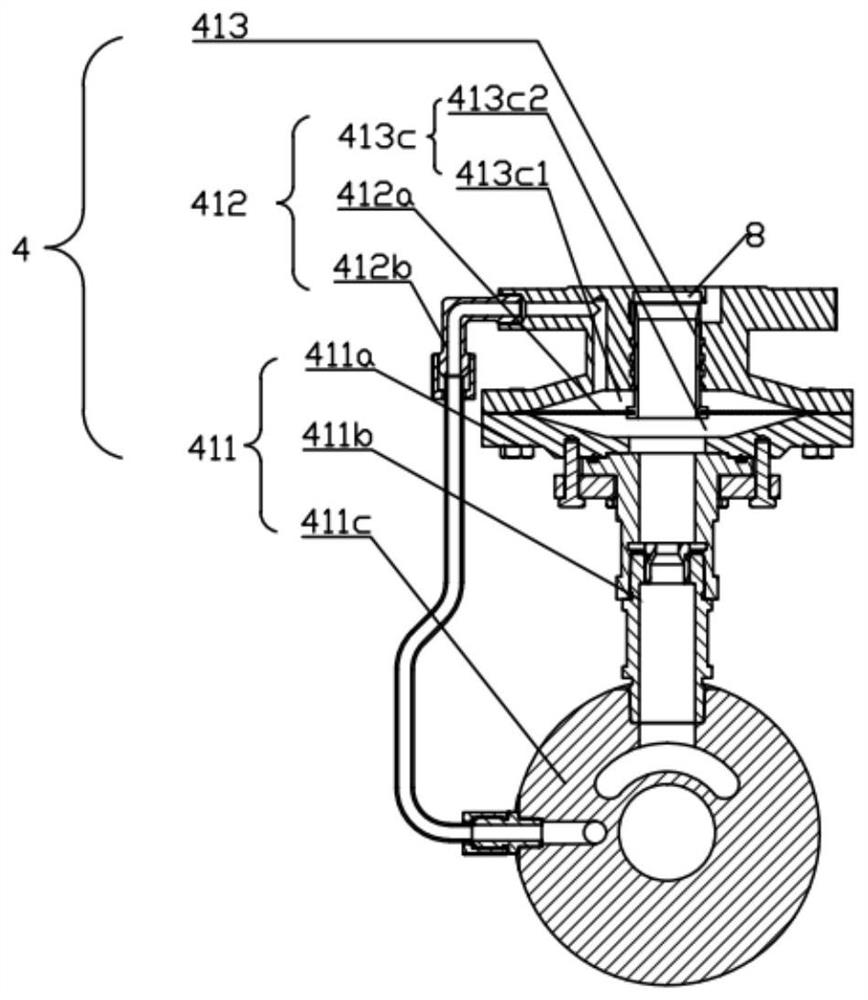

[0031] Such as Figure 3-5 As shown, the proportional mixer 4 includes a mixer body 411, a sleeve 413, and a movable control member 412. The mixer body 411 includes a cylindrical part 411a, a communication part 411b and a mix...

Embodiment 2

[0041] A fire extinguishing system, including a control module and an alarm module. The control module is connected with a pressure switch 13, a photoelectric switch 15, an electric butterfly valve 212 and an electric ball valve 7. The start and stop signals of the electric butterfly valve 212 and the electric ball valve 7 are controlled by the control module. The pressure switch 13 The pressure signal of the fire water inlet pipeline can be fed back to the control module. According to the set value, the pressure signal can be reflected in the working state. In the non-working state, the pressure signal can be used to judge whether the pipeline is leaking, that is, the switch state of the valve, and can be timely To reflect the state of the fire extinguishing device, it should be noted that the pressure switch 13 feeds back the pressure signal of the fire water pipe, and the copper tube 412b feeds back the pressure signal when the fire water flows into the mixing part 411c of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com