Clamping device capable of facilitating drill bit replacement and used for drilling machine

A technology of clamping device and drill bit, which is applied in the field of mechanical processing, can solve the problems of reducing production efficiency, easy shaking of the drill bit, and reducing the work efficiency of staff, and achieves the effects of convenient operation, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

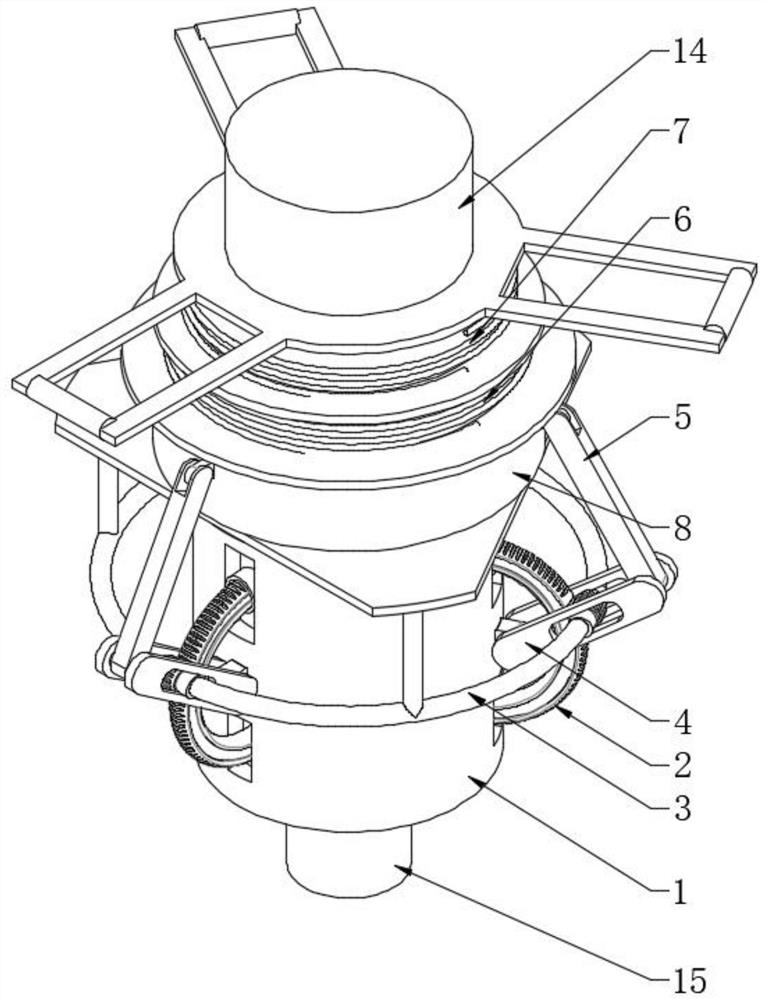

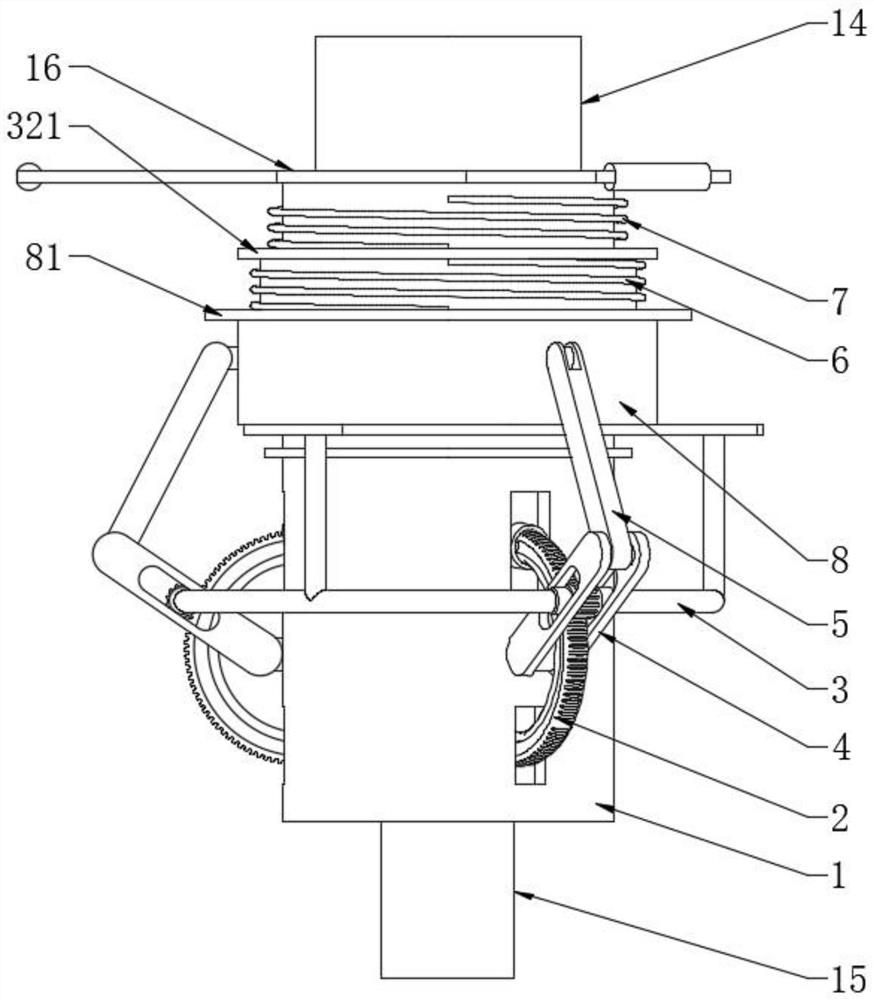

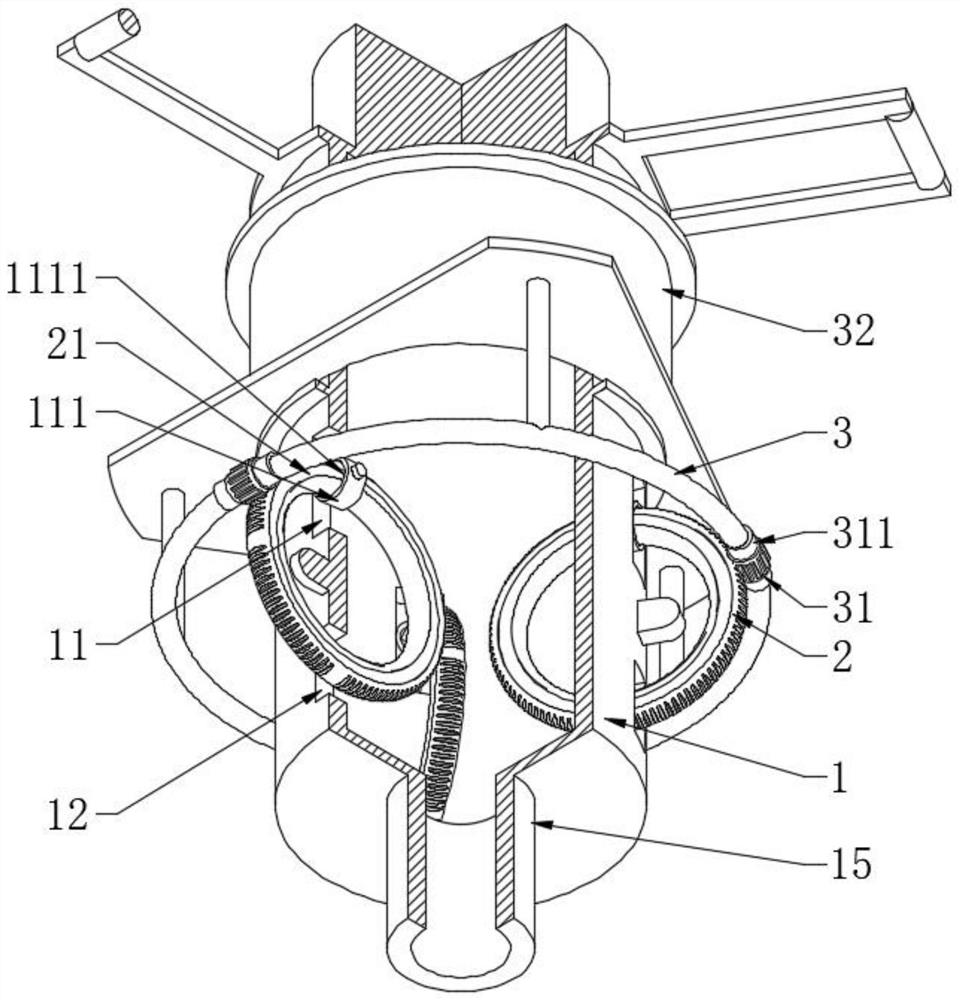

[0027] see Figure 1-4 , a kind of clamping device that is used for drilling machine to be easy to replace drill bit, comprises fixed sleeve 1, clamping ring 2, limit ring 3, pressing arm 4, spring one 6, spring two 7 and auxiliary sleeve 8, the peripheral wall of fixed sleeve 1 A positioning hole 11 and a limiting hole 12 are provided. The limiting hole 12 is located on one side of the positioning hole 11 along the axial direction of the fixed sleeve 1. The number of the positioning holes 11 is at least three and is evenly distributed in the circumferential direction. A positioning sleeve 111 is rotatably connected in the hole 11, and the forming shaft of the clamping ring 2 passes through the positioning sleeve 111 and the limiting hole 12 in sequence. The outer wall is provided with an annular groove 21 coaxially distributed, and the positioning sleeve 111 is fixedly provided with a limit shaft 1111 slidingly fitted with the annular groove 21, that is to say, the clamping r...

Embodiment 2

[0029] see Figure 4 The difference with Embodiment 1 is that the outer peripheral wall of the annular limiting plate 16 is fixedly provided with a grooved baffle 161. It should be pointed out that this grooved baffle 161 acts as a fulcrum, and the horizontal axis in the middle of the grooved baffle 161 can be Sleeve the sleeve, when it is necessary to slide control the guide sleeve 32 and the auxiliary sleeve 8, with the help of the external seesaw, with the sleeve as the fulcrum, the external of the auxiliary sleeve 8 is fixed with an annular limit plate 3 81, the annular limit plate Three 81 and annular limit plate one 321 act as contact baffles of the seesaw, and then manual control is convenient for operation.

[0030] Working principle: When in use, the docking shaft 14 is fixedly connected with the output shaft of the drilling machine. When replacing the drill bit, use the pry plate to pry the ring-shaped limit plate 3 81 with the grooved baffle 161 as the fulcrum, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com