Device and method for installing heavy split type beveling machine

A split-type and beveling machine technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of easy safety accidents for installers, damage to components caused by beveling machines, and increased installation difficulty, and achieve production costs. Low, ensure safety, accurate cutting effect

Active Publication Date: 2021-12-03

PIPECHINA SOUTH CHINA CO +1

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The current installation method of the heavy-duty split beveling machine is: hoist the heavy-duty beveling machine to the designated position of the pipeline for installation by using hoisting equipment, and then manually align the beveling machine and the center of the pipeline. This method is extremely inconvenient. Especially when installing slope pipelines, it

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to view more

Login to view more PUM

Login to view more

Login to view more Abstract

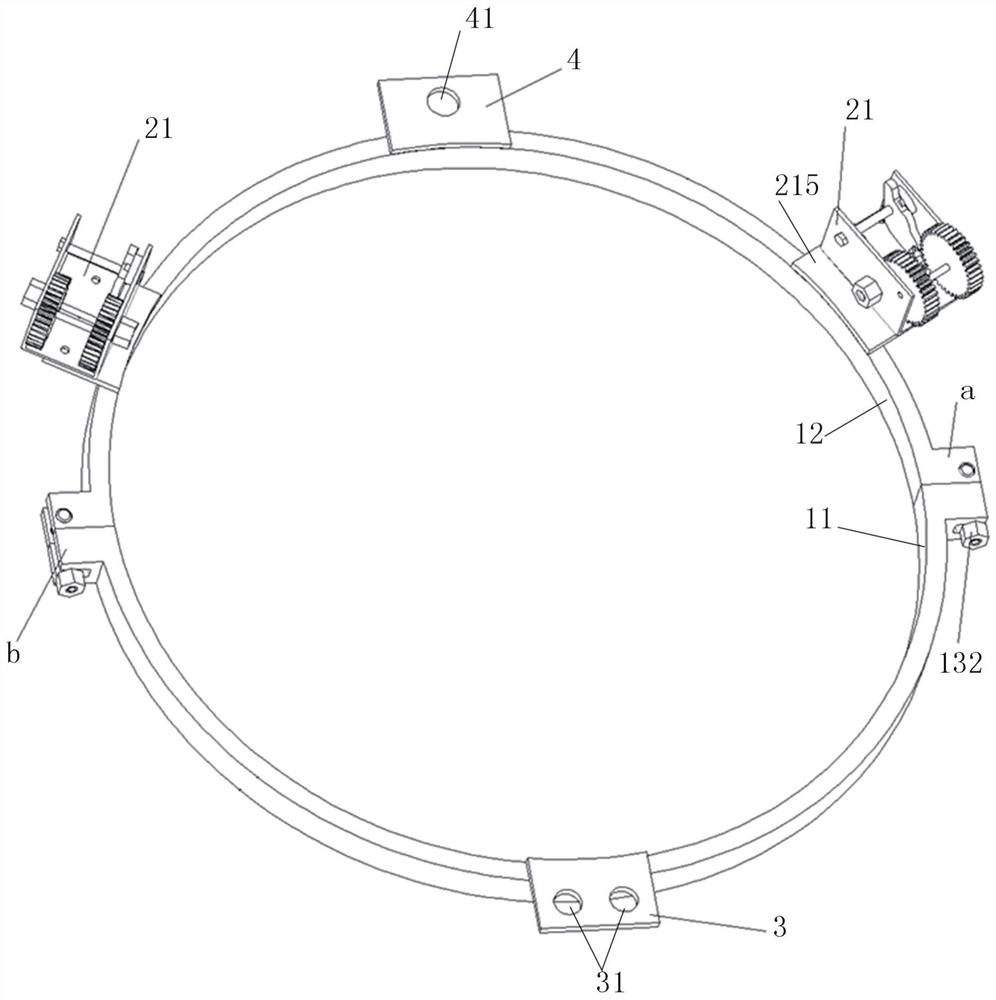

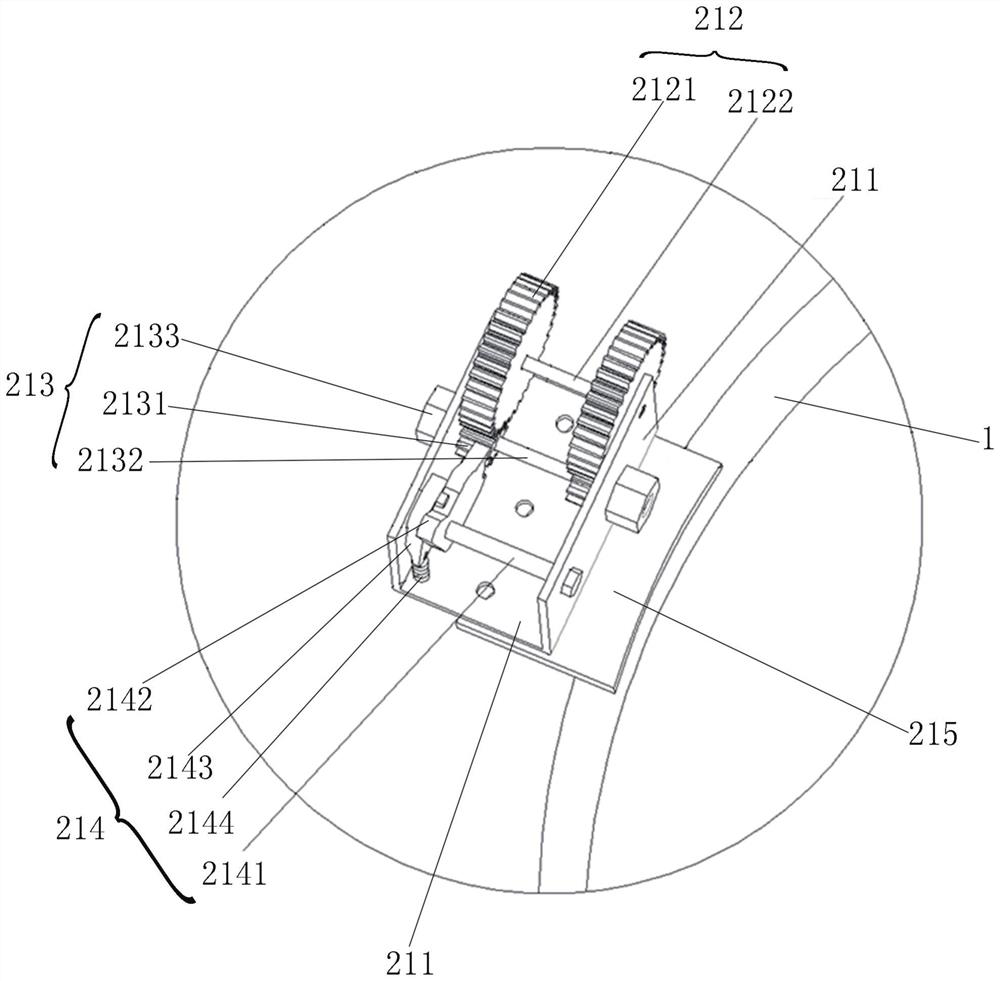

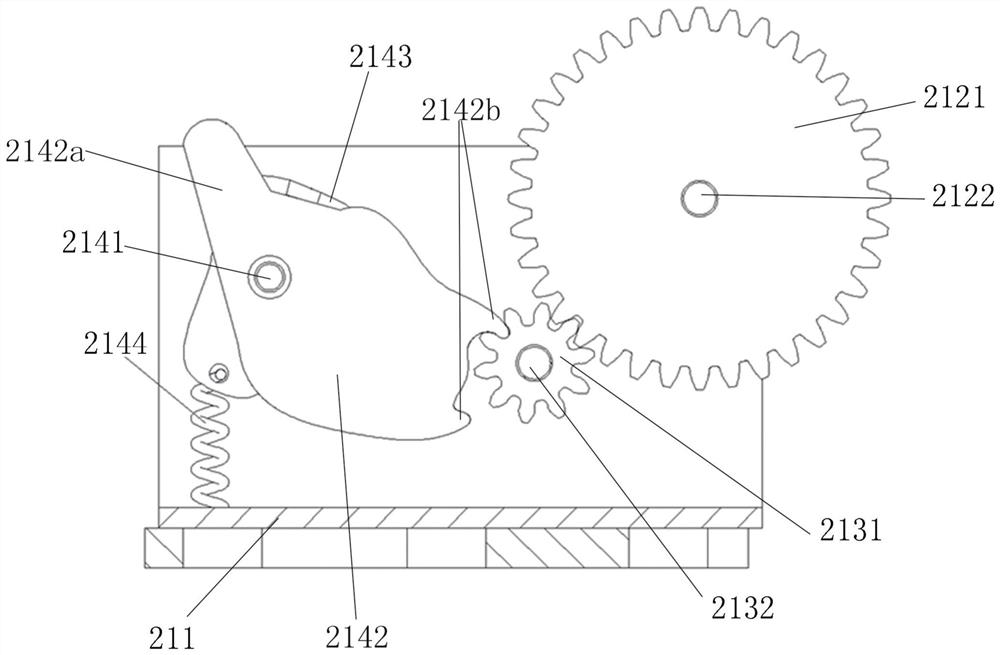

The invention provides a device and method for installing a heavy split type beveling machine. The device comprises a fixing unit, a connecting unit and an adjusting unit, wherein the fixing unit comprises at least two arc-shaped sections and a fixing assembly; the connecting unit comprises at least two ropes; and the adjusting unit is installed on the fixing unit, and can be used for winding and unwinding the at least two ropes simultaneously or separately. The method comprises the steps that the fixing unit is fixed to a pipe body of a pipeline to be operated; the two ends of the at least two ropes are connected to the heavy split type beveling machine and the adjusting unit separately; and the ropes are tightened or loosened through the adjusting unit, and therefore the heavy split type beveling machine is installed. According to the device and method for installing the heavy split type beveling machine, the position of the installation device can be quickly adjusted to achieve the purpose of adjusting the heavy split type beveling machine, and the safety of operators can be ensured.

Description

technical field [0001] The invention relates to the technical field of pipeline installation, in particular to a device and an installation method for installing a heavy-duty split beveling machine. Background technique [0002] The heavy-duty split beveling machine is a portable machine tool developed for the cutting and beveling of heavy-duty pipes such as thick-walled pipes and large-diameter pipes and flange surface processing. The heavy-duty split beveling machine can cut and bevel the pipeline by metal cutting method at the field pipeline construction site. [0003] The current installation method of the heavy-duty split beveling machine is: hoist the heavy-duty beveling machine to the designated position of the pipeline for installation by using hoisting equipment, and then manually align the beveling machine and the center of the pipeline. This method is extremely inconvenient. Especially in the installation of slope pipelines, it takes 6 to 8 people to install the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B25B11/02

CPCB25B11/02

Inventor 汪嘉伟申坤周顺荣杨利岗汪珍

Owner PIPECHINA SOUTH CHINA CO

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap