Double-arm robot

A robot and dual-arm technology, applied in the field of robotics, can solve the problems of reducing manufacturing costs, the rhythm cannot keep up, and the robot cannot be responsible for multiple work stations at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

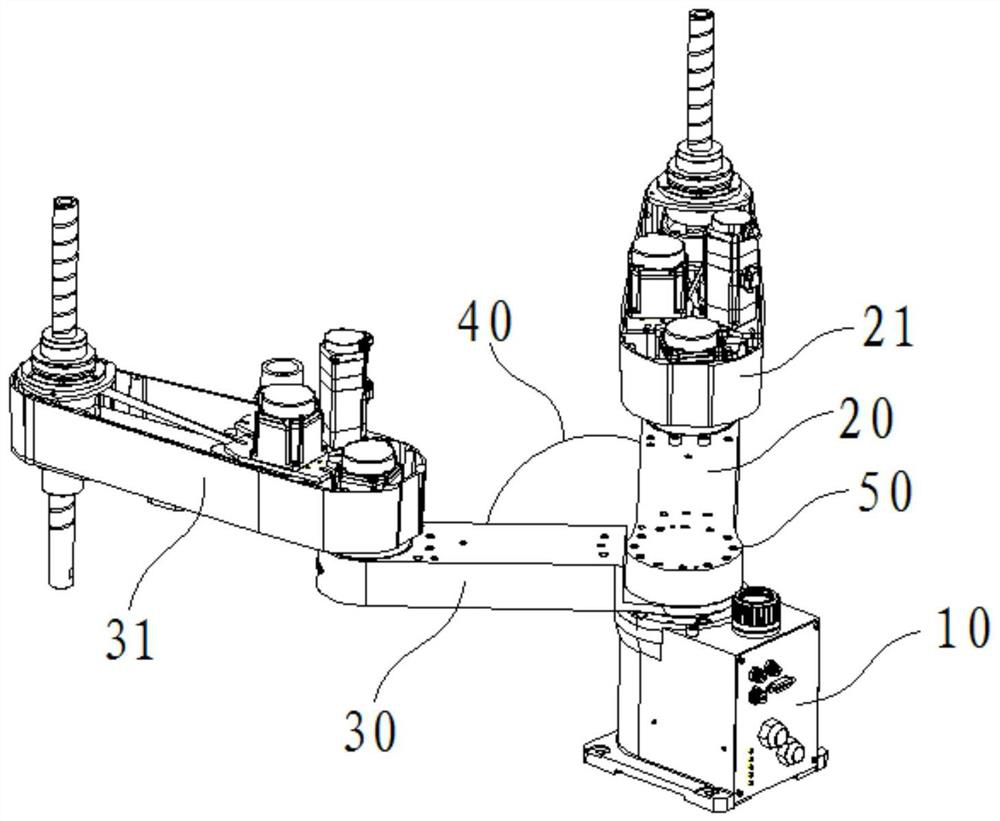

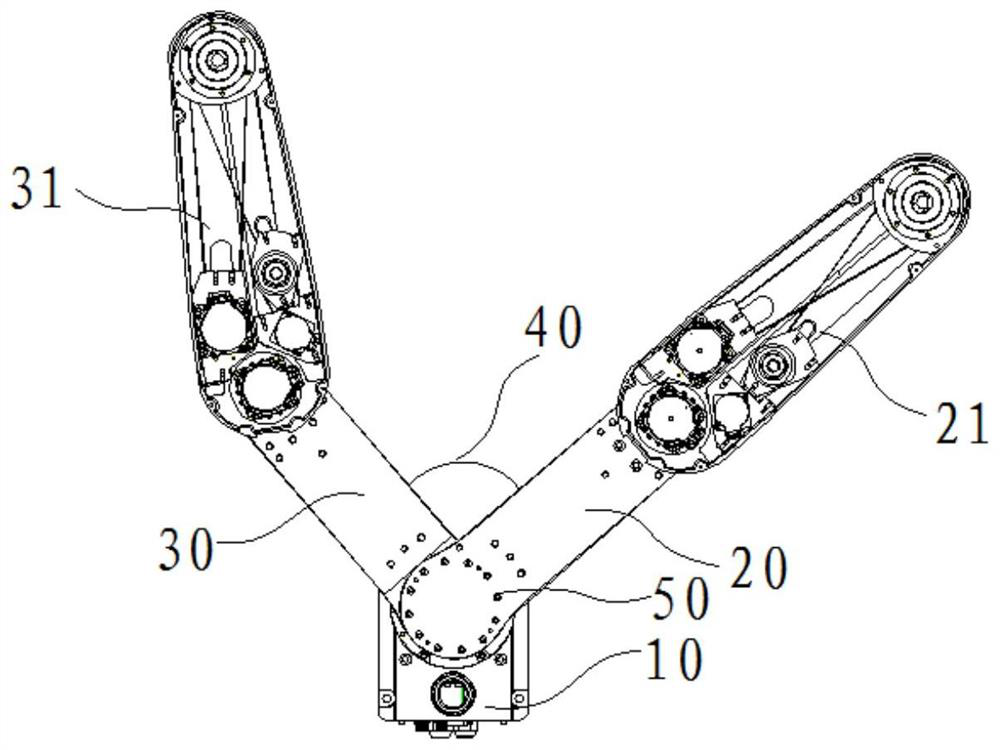

[0032] In order to make the purpose, technical solution and advantages of the application clearer, the application will be further described in detail below in conjunction with the accompanying drawings.

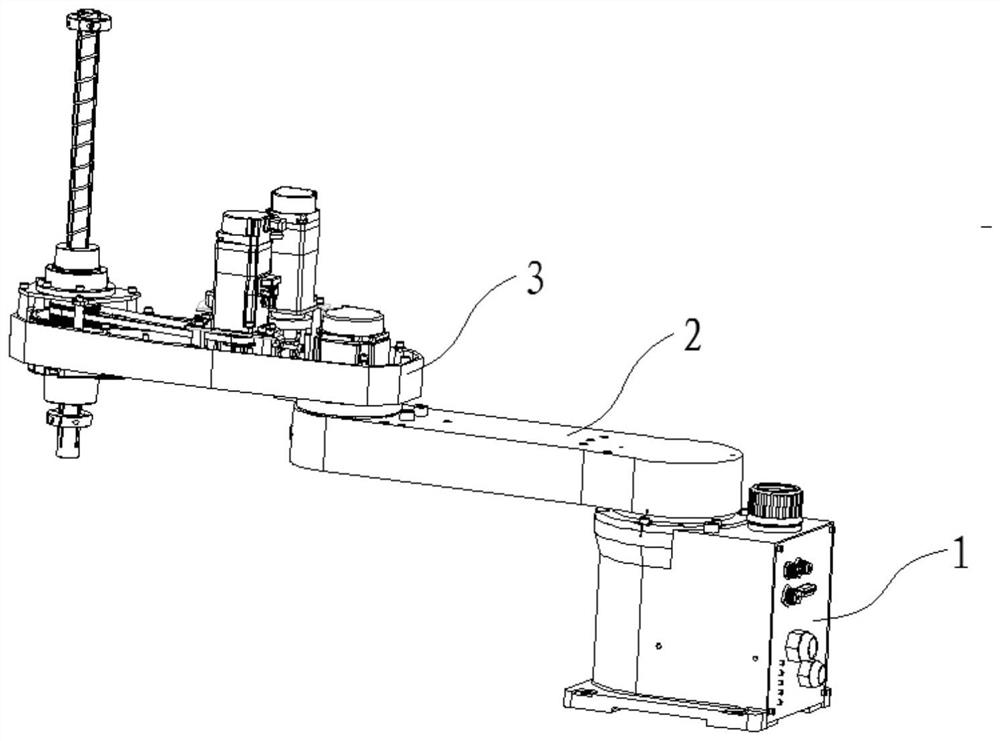

[0033] In order to facilitate the understanding of the dual-arm robot provided by the embodiment of the present application, firstly, its application scenario is explained, such as figure 1 As shown in , a conventional single-arm SCARA robot has a base 1 on which a large arm 2 is connected through a reducer, and the large arm 2 is connected to a small arm 3 .

[0034] It can be seen that one SCARA robot needs to correspond to one station process to meet the production cycle requirements. A single-arm SCARA robot cannot be responsible for multiple station processes at the same time, resulting in higher production equipment costs. Moreover, the existing dual-arm robot is difficult to manufacture, the process is cumbersome, and the manufacturing cost is relatively high, so it d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com