Automatic integrated forming equipment and method for 3D luminous character printing

A technology of molding equipment and luminous characters, which is applied in the field of 3D printing, can solve the problems of increasing the probability of product damage, cumbersome process flow, and increasing labor costs, so as to save costs, increase the success rate, and realize the effect of integrated automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

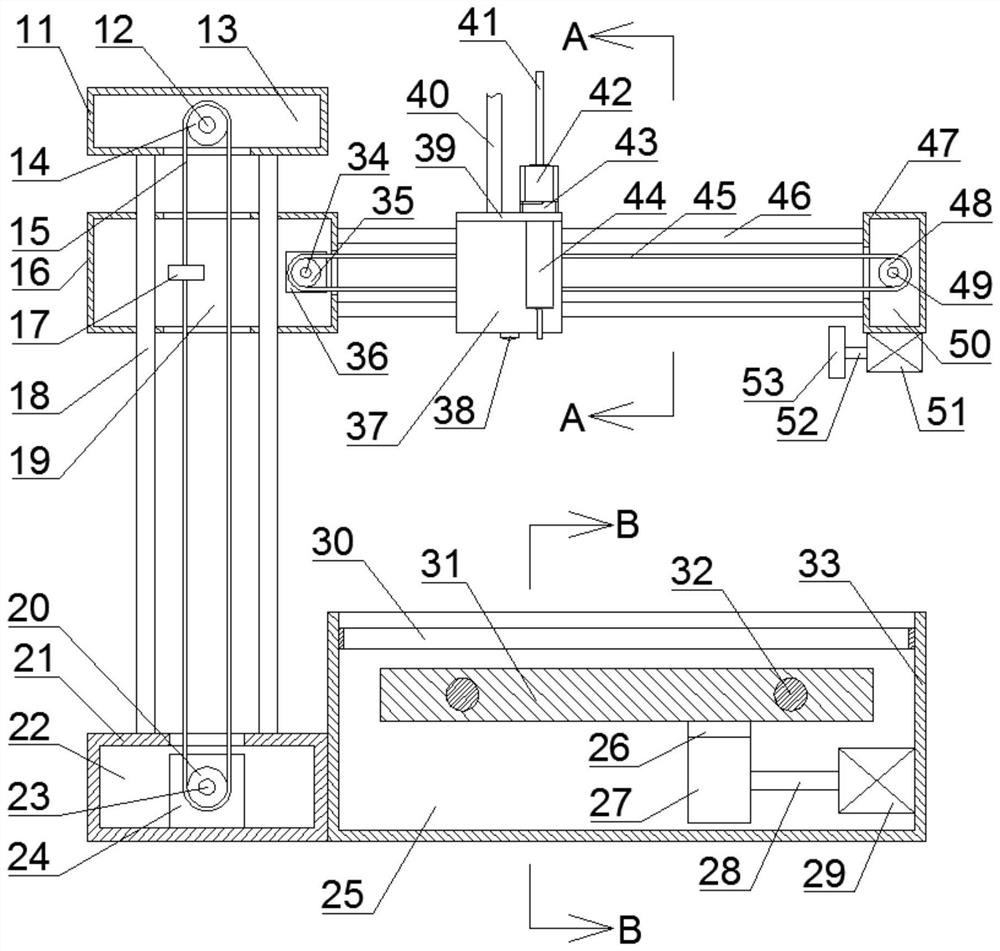

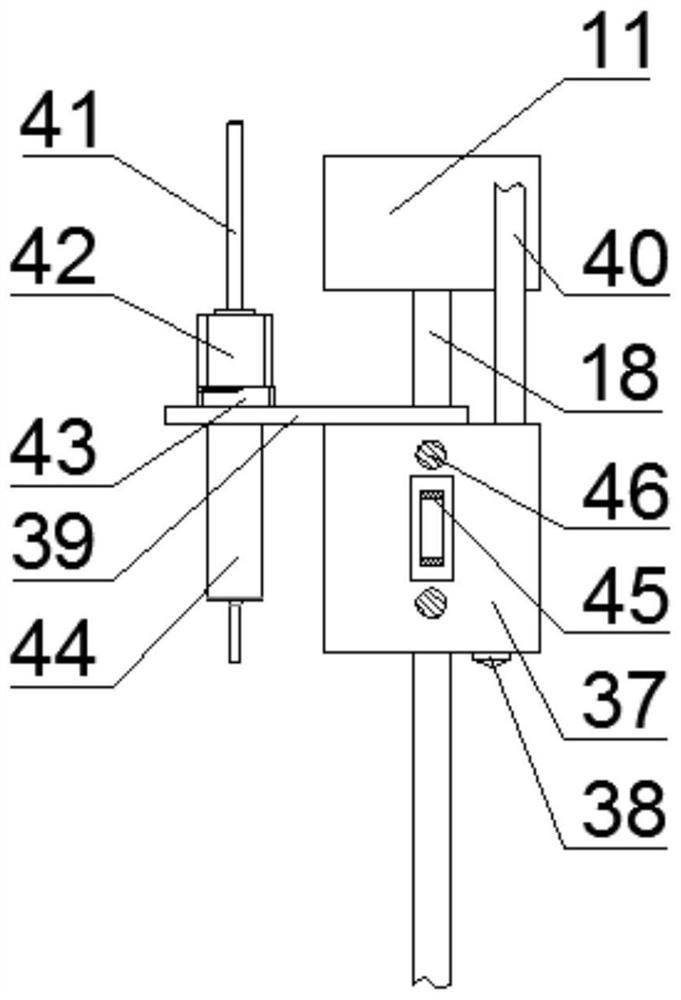

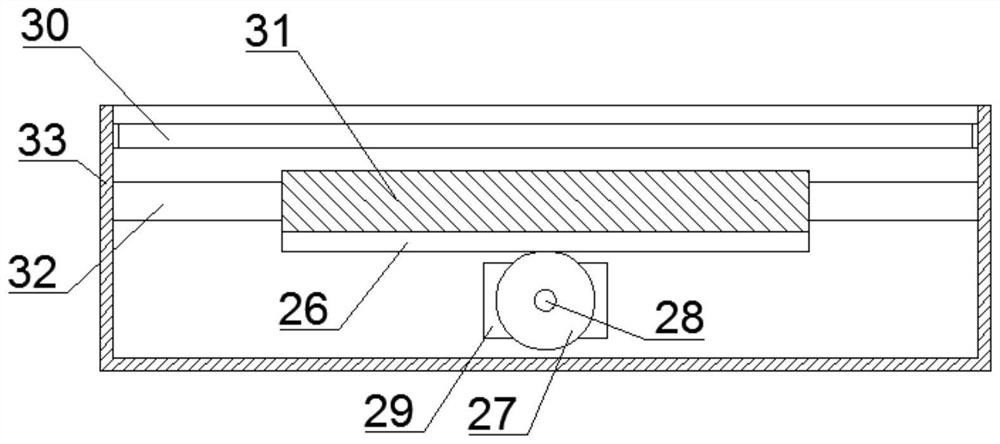

[0038] Combine below Figure 1-6 Describe the specific implementation of the present invention, an automatic integrated molding equipment for 3D luminous character printing, including a control block 37, one end of the control block 37 is fixed with a nozzle 38, and the end of the control block 37 is far away from the nozzle 38 Fixedly be provided with fixed bracket 39, one side of described control block 37 is provided with the slot 43 that is fixed on described fixed bracket 39, and one end of described slot 43 is fixedly provided with screw motor 42, and described screw motor 42 is controlled with a screw 41 that runs through the screw motor 42, and the end of the slot 43 away from the screw motor 42 is fixedly provided with a needle cylinder 44, and a piston 54 is slidably arranged in the needle cylinder 44, so that One end of the piston 54 close to the screw motor 42 is fixedly connected to one end of the screw rod 41 .

[0039] Beneficially, a rubber strip 40 is dispose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com