Discharge device for discharging pressed products from rotary press

A discharge device, rotary technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of high energy consumption, high energy demand, large structure space demand, etc., to increase the structure space, The effect of increasing energy demand and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Unless otherwise stated, the same reference numerals denote the same objects in the various figures.

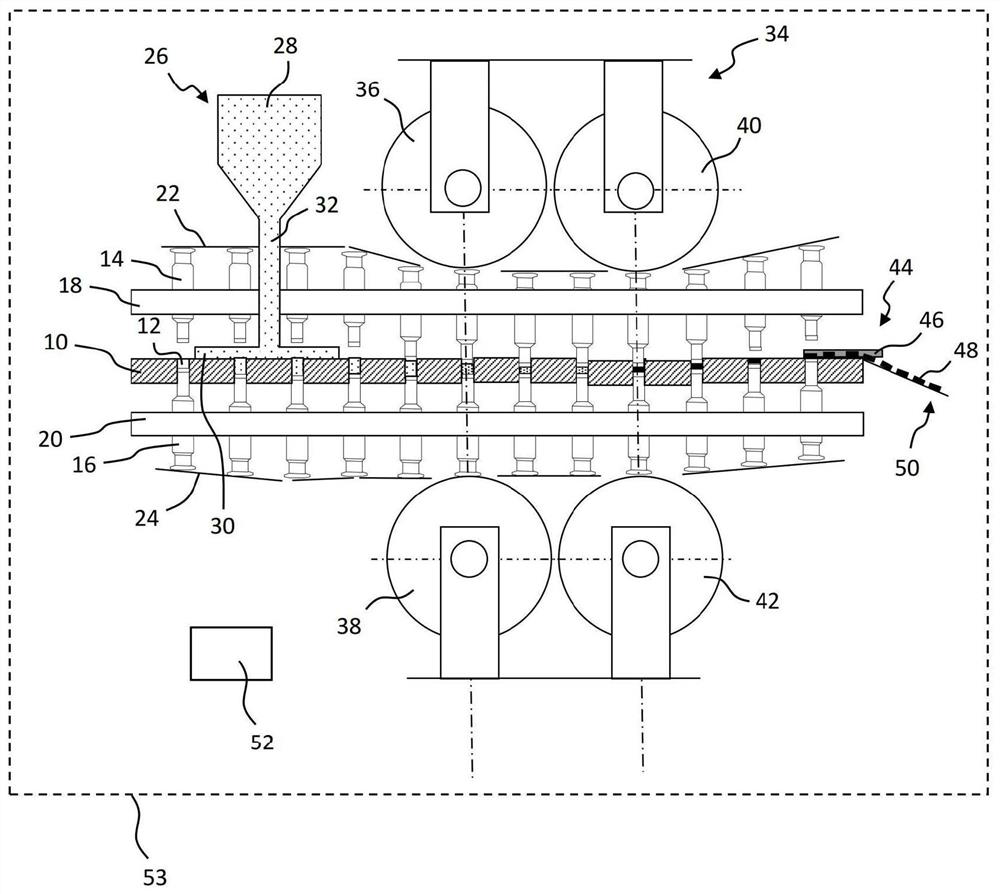

[0032] exist figure 1 The rotary press shown in , in particular a rotary tablet press, comprises a rotor driven in rotation by a rotary drive, said rotor having a die plate 10 with a plurality of receptacles 12 . The receptacles 12 can be formed, for example, by holes in the mold plate 10 . Furthermore, the rotor comprises a plurality of upper punches 14 and lower punches 16 which revolve synchronously with the die plate 10 . The upper punch 14 is axially guided in an upper punch guide 18 and the lower punch 16 is axially guided in a lower punch guide 20 . The axial movement of the upper punch 14 and the lower punch 16 during the rotation of the rotor is controlled by the upper control cam element 22 and the lower control cam element 24 . The rotary press also includes a filling device 26 which has a filling reservoir 28 and a filling chamber 30 which are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com