A kind of high-barrier bromobutyl rubber with alternating layered structure and preparation method thereof

A technology of bromobutyl rubber and alternating layers, which is applied in the field of composite materials, can solve the problems of reducing air tightness, high production costs, and complicated procedures, and achieve the effects of improving gas barrier properties, improving mechanical properties and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Preparation of carbon black modified bromobutyl rubber (BIIR / CB):

[0044] Before the experiment, the carbon black was dried in a drying oven at 105 °C ± 2 °C for 2 h. Weigh the materials according to the ratio in Table 1, set the temperature of the front and rear rolls of the open mill (LRMR-S-150 / W, Thailand Labtech Co., Ltd.) to be 45°C and 35°C respectively, and the roll speed ratio to be 1.25. After the mill was stabilized for 30min, put the bromobutyl rubber (BIIR) into the mill, make it roll, according to zinc oxide, stearic acid, magnesium oxide, carbon black, tackifier, naphthenic oil, Add the small materials to the roller in the order of sulfur and accelerator. After each feeding, the left and right knives are cut twice to make the components fully mixed. The roller distance is reduced to 0.5mm, and the triangular bag and the roll are each 5 times. time, and finally adjust the required roller distance to eject the sheet.

[0045] Using the above-mentioned pr...

experiment example

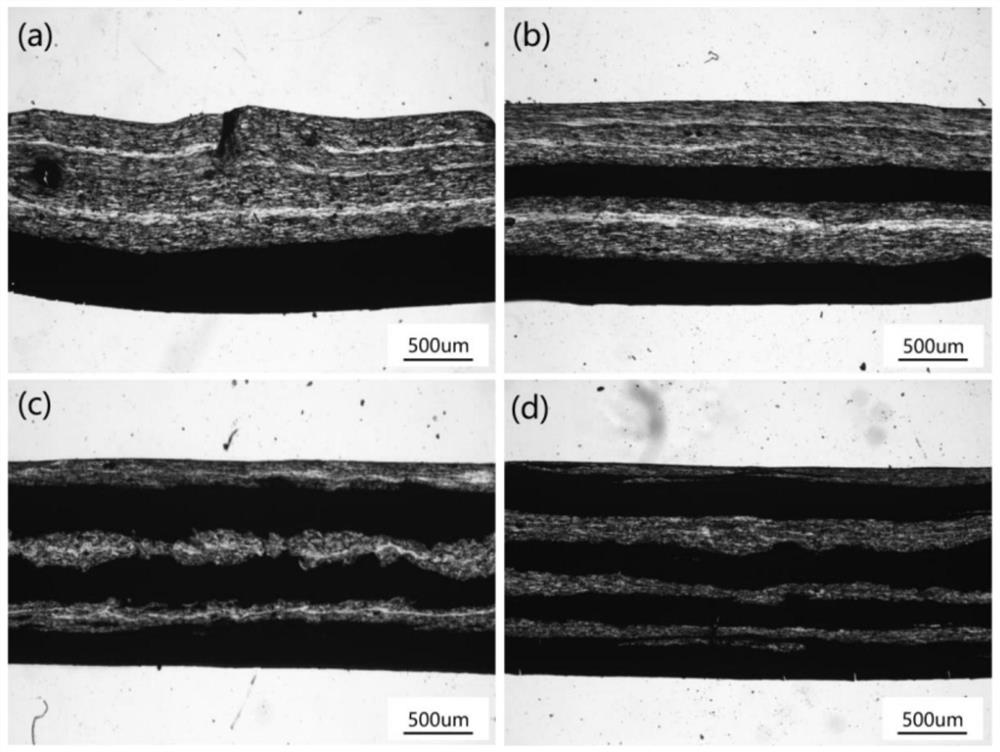

[0076] 1. Microstructure of layered rubber material

[0077] Under an optical microscope, the cross-sectional microstructures of the layered rubber materials of Examples 3, 5, 6, and 7 were observed, and the results were as follows: figure 1 As shown, a-d in the figure correspond to Embodiments 3, 5, 6, and 7, respectively.

[0078] from figure 1 As can be seen from the above, in a-d, it can be clearly seen that the layers of 2 layers, 4 layers, 6 layers and 8 layers. The distribution of graphene and carbon black in the composite material is uniform, and the BIIR / CB layers and BIIR / mGO layers are alternately arranged. Since the matrix is all BIIR, there is no obvious phase interface. In BIIR, graphene is arranged in layered sheets and the content is relatively small, and it appears as well-ordered layered barrier walls on the side of the material.

[0079] 2. Gas barrier properties of layered rubber materials

[0080] The carbon black modified bromobutyl rubber, graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com