A kind of nano drag reducer and its preparation method and slick water fracturing fluid

A drag reducer, nanotechnology, applied in the directions of nanotechnology, chemical instruments and methods, drilling compositions, etc., to achieve the effect of improving dispersion, increasing stability, and increasing rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The present embodiment prepares a kind of nano drag reducing agent, comprises the following steps:

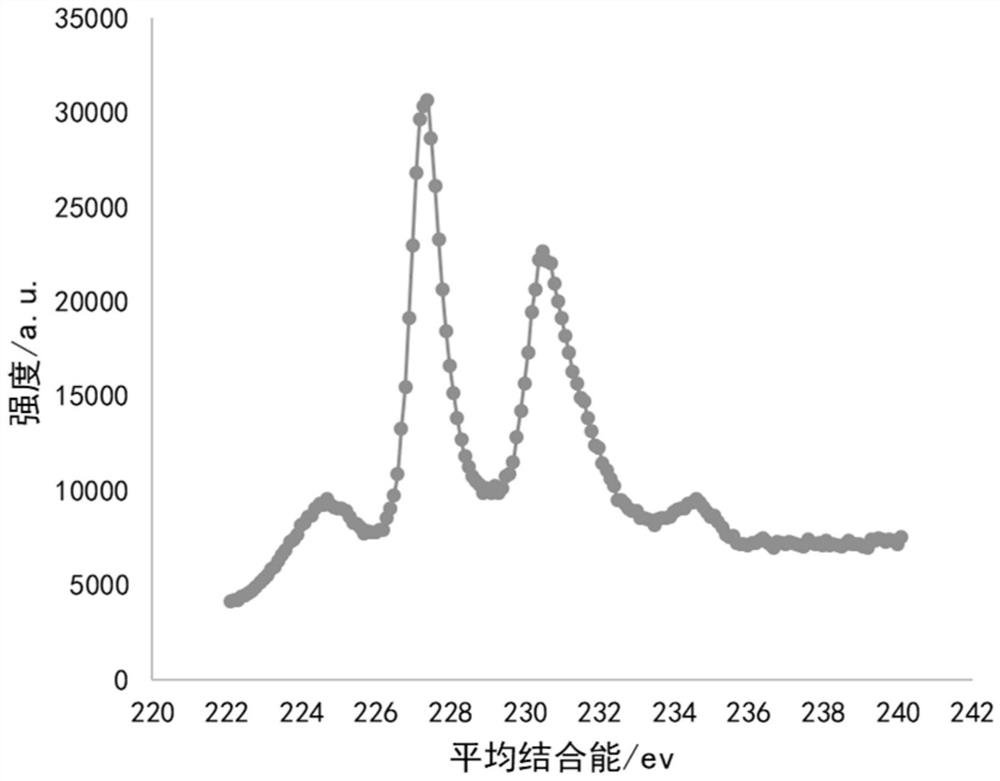

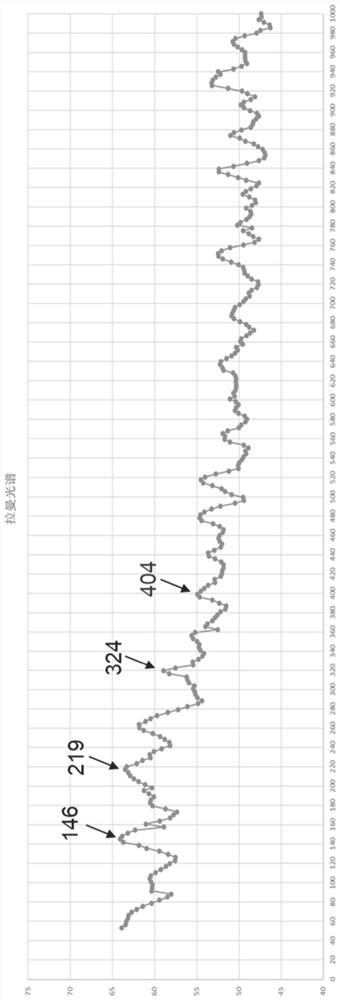

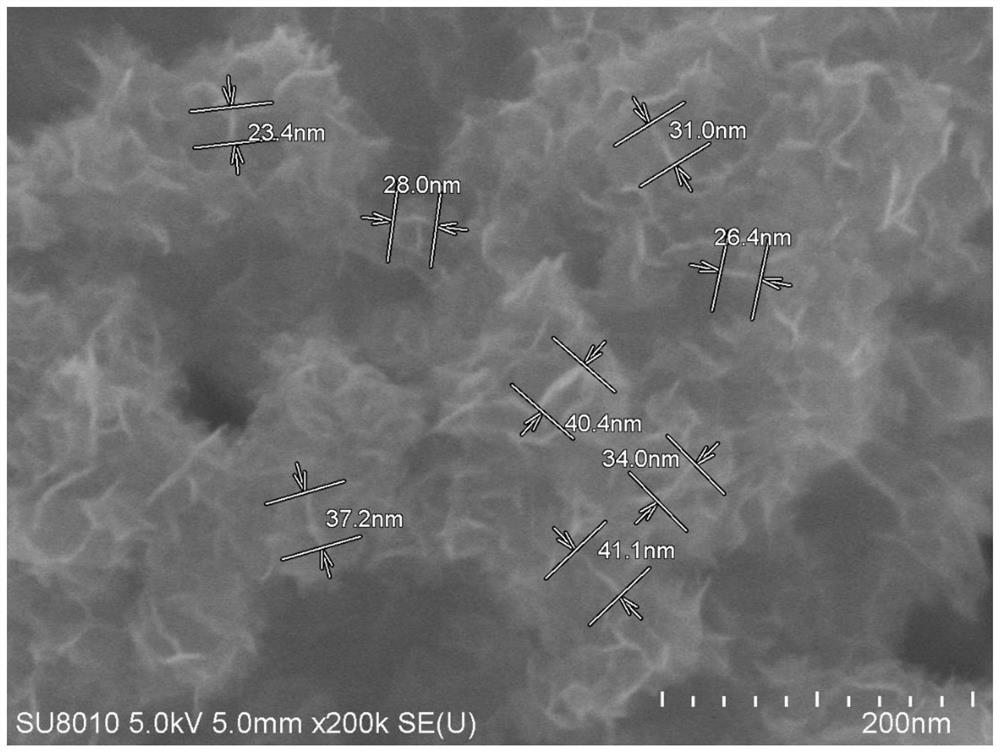

[0065] 1) Add 1g of molybdenum trioxide powder, 5g of thioformamide and 8g of citric acid into 100mL of deionized water and stir for 30min; then pour the mixed solution into a hydrothermal reactor and react at 180°C for 12 hours. Then wash with deionized water to obtain molybdenum disulfide nanosheets. figure 1 It is the XPS experimental data of molybdenum disulfide nanosheets, the average binding energy of 1T type molybdenum disulfide is 227,231ev, and the average binding energy of 2H type molybdenum disulfide is 229ev, 232ev; figure 2 It is the Raman spectrum data of molybdenum disulfide nanosheets, where the Raman spectrum is 146cm -1 The characteristic peaks show that it is 1T molybdenum disulfide. image 3 It is the SEM image of molybdenum disulfide nanosheets, the size of which is between 23.4nm and 41.1nm.

[0066] 2) The synthesized molybdenum disulfide nanos...

Embodiment 2

[0069] The present embodiment prepares a kind of nano drag reducing agent, comprises the following steps:

[0070] 1) Add 0.1g of molybdenum trioxide powder, 1g of sodium sulfide and 0.6g of hydrazine hydrate into 50mL of deionized water and stir for 30min; then pour the mixed solution into a hydrothermal reactor and react at 220°C for 6 hours. Then wash with deionized water to obtain molybdenum disulfide nanosheets.

[0071] 2) The synthesized molybdenum disulfide nanosheets and acrylamide were added into deionized water at a mass ratio of 1:1, ultrasonicated at room temperature for 30 min; then stirred at room temperature at 1000 rpm for 24 hours. Then wash with deionized water to remove unreacted acrylamide, and dry at 50°C to obtain molybdenum disulfide nanosheets with surface-modified functional groups.

[0072] 3) Add 0.1g of molybdenum disulfide nanosheets with surface-modified functional groups and 4g of acrylamide into a Shrek bottle, use deionized water as the react...

Embodiment 3

[0074] The present embodiment prepares a kind of nano drag reducing agent, comprises the following steps:

[0075] 1) Add 1g of molybdenum trioxide powder, 8g of thiourea, 3g of sodium sulfide and 10g of urea into 100mL of deionized water and stir for 30min; then pour the mixed solution into a hydrothermal reactor and react at 200°C for 10 hours. Then wash with deionized water to obtain molybdenum disulfide nanosheets.

[0076] 2) The synthesized molybdenum disulfide nanosheets and acrylamide were added into deionized water at a mass ratio of 1:1, ultrasonicated at room temperature for 30 min; then stirred at room temperature at 1000 rpm for 24 hours. Then wash with deionized water to remove unreacted acrylamide, and dry at 50°C to obtain molybdenum disulfide nanosheets with surface-modified functional groups.

[0077] 3) Add 1g of molybdenum disulfide nanosheets with surface-modified functional groups, 4g of acrylamide and 4g of acrylic acid into a Shrek bottle, use deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com