Ultrafine powder reinforced rubber as well as preparation method and application thereof

A technology of reinforcing rubber and ultra-fine powder, which is applied in the field of composite rubber, can solve the problems of declining production of natural gas semi-reinforcing carbon black, stagnant production technology, and high natural gas price, and achieve good aging resistance and wear resistance High, good tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of modified fly ash in superfine powder reinforced rubber, comprising the steps of:

[0032] 1) drying the fly ash with a particle size of 150 mesh to constant weight to obtain superfine fly ash;

[0033] 2) Add the superfine fly ash and 0.5 part of activator stearic acid into deionized water together, and after ball milling for 8 hours, evaporate the deionized water at 100°C and dry to constant weight to obtain pretreated powder coal ash;

[0034] 3) Heat the pretreated fly ash in step 2) to 110°C, add 2 parts of coupling agent I and absolute ethanol, first add the silane coupling agent, and stir at constant temperature for 15 minutes, then add the carbonate coupling agent , and stirred at constant temperature for 6 minutes to obtain modified fly ash;

[0035] Wherein, the volume ratio of the absolute ethanol to the coupling agent I is 1:1.

[0036] A preparation method of superfine powder reinforced rubber, comprising the steps of:

[0037] 1)...

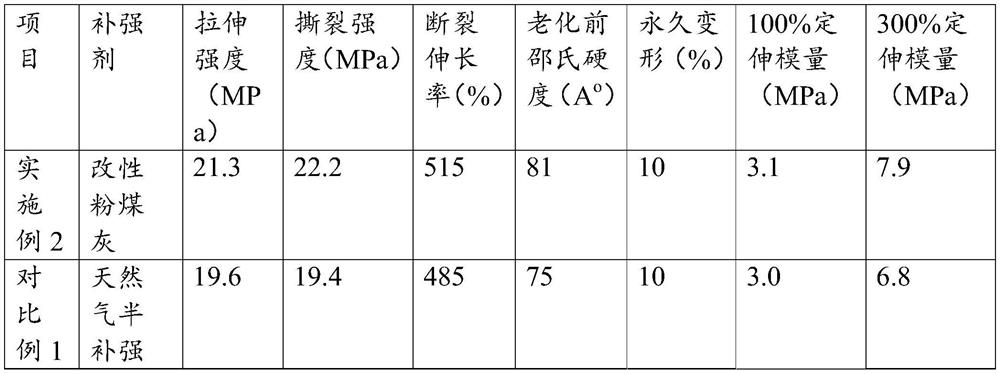

Embodiment 2

[0042] A preparation method of modified fly ash in superfine powder reinforced rubber, comprising the steps of:

[0043] 1) drying the fly ash with a particle size of 100 mesh to constant weight to obtain superfine fly ash;

[0044] 2) Add the superfine fly ash and 0.75 parts of activator stearic acid into deionized water together, and after ball milling for 6 hours, evaporate the deionized water at 110°C and dry to constant weight to obtain pretreated powder coal ash;

[0045] 3) Heat the pretreated fly ash in step 2) to 120°C, add 3 parts of coupling agent I and absolute ethanol, first add the silane coupling agent, and stir at constant temperature for 12 minutes, then add the carbonate coupling agent , and stirred at constant temperature for 8 minutes to obtain modified fly ash;

[0046] Wherein, the volume ratio of the absolute ethanol to the coupling agent I is 1.5:1.

[0047] A preparation method of superfine powder reinforced rubber, comprising the steps of:

[0048] ...

Embodiment 3

[0053] A preparation method of modified fly ash in superfine powder reinforced rubber, comprising the steps of:

[0054] 1) drying the fly ash with a particle size of 60 mesh to constant weight to obtain superfine fly ash;

[0055] 2) Add the superfine fly ash from step 1) and 1 part of activator stearic acid into deionized water, after ball milling for 5 hours, evaporate the deionized water at 120°C and dry to constant weight to obtain pretreated powder coal ash;

[0056] 3) Heat the pretreated fly ash in step 2) to 130°C, add 4 parts of coupling agent I and absolute ethanol, first add the silane coupling agent, and stir at constant temperature for 10 minutes, then add the carbonate coupling agent , and stirred at constant temperature for 10 minutes to obtain modified fly ash;

[0057] Wherein, the volume ratio of the absolute ethanol to the coupling agent I is 2:1.

[0058] A preparation method of superfine powder reinforced rubber, comprising the steps of:

[0059] 1) W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com