Novel self-repairing waterborne polyurethane as well as preparation method and application thereof

A water-based polyurethane and self-repairing technology, applied in the field of polyurethane materials, can solve the problems of increased water absorption, limited material use, and short service life, and achieve the effects of increased strength, high mechanical strength, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

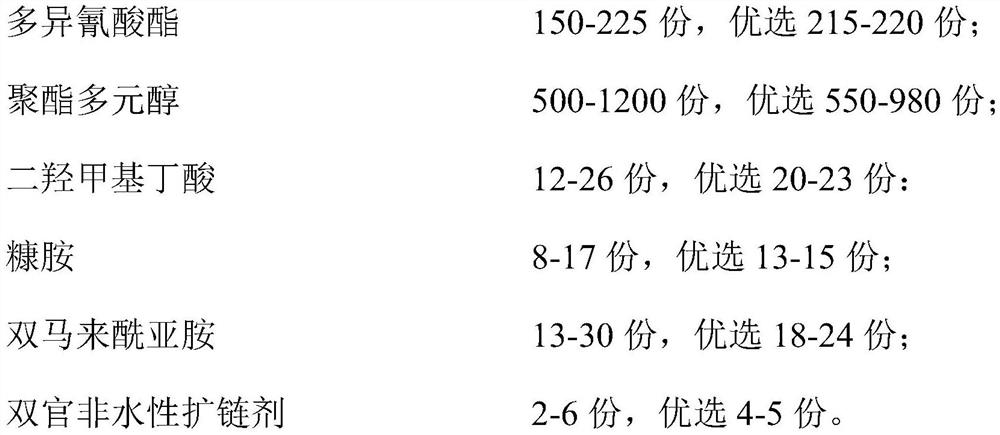

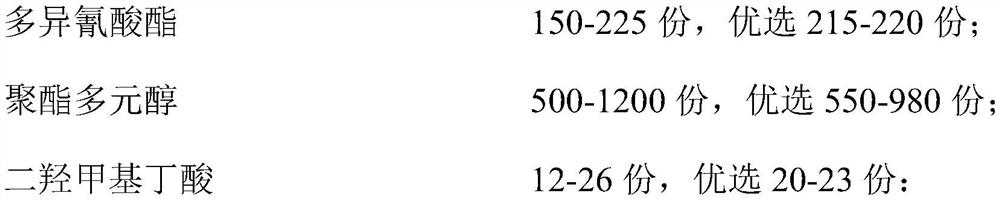

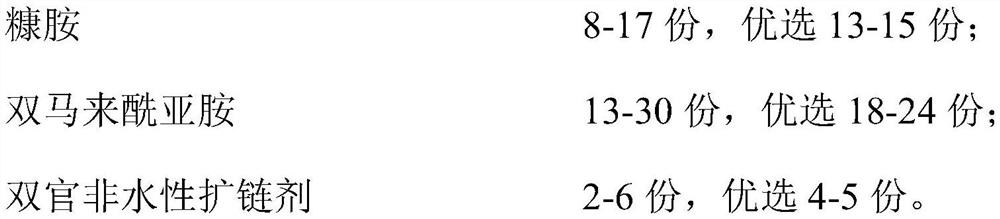

[0029] A preparation method of novel self-repairing water-based polyurethane, comprising the following steps:

[0030] 1) In the presence of an organic solvent, mix dimethylol butyric acid and furfurylamine to obtain a trifunctional monomer solution.

[0031] Wherein, the mixing temperature of dimethylolbutyric acid and furfurylamine is 5-40°C, for example including but not limited to 5°C, 10°C, 15°C, 20°C, 25°C, 30°C, 35°C, 40°C, preferably 15-25°C; the mixing time is 10-30min, for example including but not limited to 15min, 18min, 20min, 23min, 25min, preferably 15-25min.

[0032] 2) Mix and react the polyisocyanate, polyester polyol, and the trifunctional monomer solution obtained in step 1), and then add bismaleimide for water-based reaction to obtain a polyurethane solution.

[0033] Wherein, the reaction temperature of the mixed reaction of polyisocyanate, polyester polyol, and the trifunctional monomer solution obtained in step 1) is 75-80°C, for example including but ...

Embodiment 1

[0075] Preparation of self-healing waterborne polyurethane material:

[0076] 1) Synthesis of monomer mixed solution: Add 200 g of acetone, 23 g of dimethylol butyric acid, and 15 g of furfurylamine into a four-neck flask and stir at room temperature for 25 minutes to obtain a mixed solution of trifunctional monomers.

[0077] 2) Polyurethane synthesis process: continue to add 215g of MDI, 1140g of PC2000, and 1.1g of dibutyltin dilaurate into the four-neck flask, pass through nitrogen protection, heat up to 80°C, react for 3 hours, then add 28g of bismaleimide, The reaction was continued for 2h to obtain a polyurethane solution.

[0078] 3) Preparation of polyurethane emulsion: Use a peristaltic pump to add ultrapure water with twice the polyurethane content at a constant speed within 10 minutes, use a stirring blade to shear and disperse, and disperse at 200rpm for 30 minutes to obtain a stable emulsion, add 4g of ethylenediamine to extend the chain, and stir 5min. Use a r...

Embodiment 2

[0081] Preparation of self-healing waterborne polyurethane material:

[0082] 1) Synthesis of monomer mixed solution: 120 g of tetrahydrofuran, 23 g of dimethylol butyric acid, and 15 g of furfurylamine were added to a four-necked flask and stirred at room temperature for 15 minutes to obtain a mixed solution of trifunctional monomers.

[0083] 2) Polyurethane synthesis process: continue to add 214g of MDI and 1100g of PEA2000 into a four-neck flask, pass through nitrogen protection, raise the temperature to 78°C, react for 3h, then add 28g of bismaleimide, continue to react for 2h, and obtain a polyurethane solution.

[0084] 3) Preparation of polyurethane emulsion: Use a peristaltic pump to add ultrapure water with twice the polyurethane content at a constant speed within 10 minutes, use a stirring blade to shear and disperse, and disperse at 600rpm for 25 minutes to obtain a stable emulsion. Add 4 parts of ethylenediamine and then extend the chain. Stir for 5min. Use a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com