A method for automatic adjustment and control of ship attitude

An automatic adjustment and control method technology, applied in the field of ships, can solve the problems of low efficiency of artificial ship attitude adjustment, insufficient or over-adjusted ship attitude adjustment, over-adjustment and improper adjustment, etc. capacity, ensuring stability and personnel comfort, avoiding the effects of under-adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

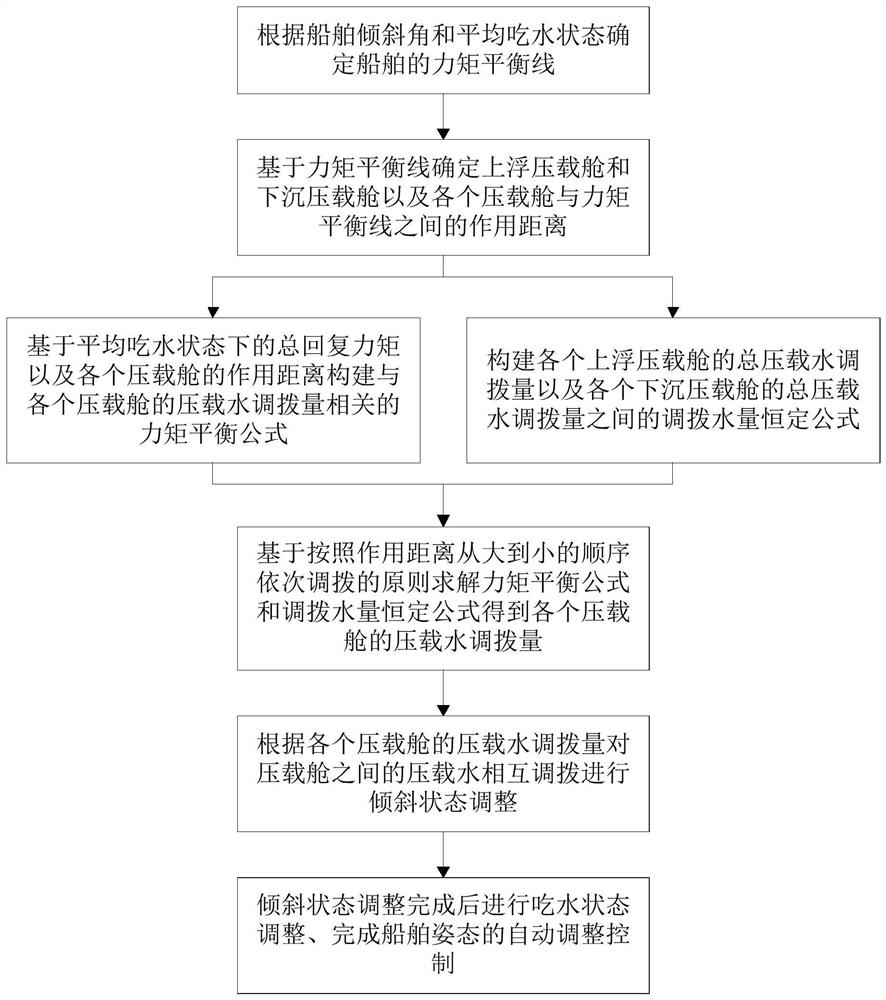

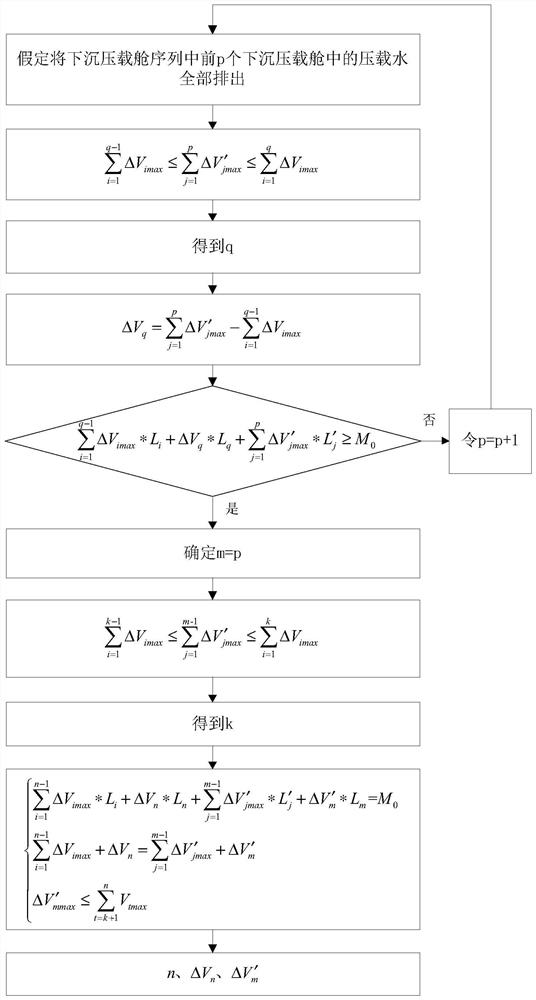

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

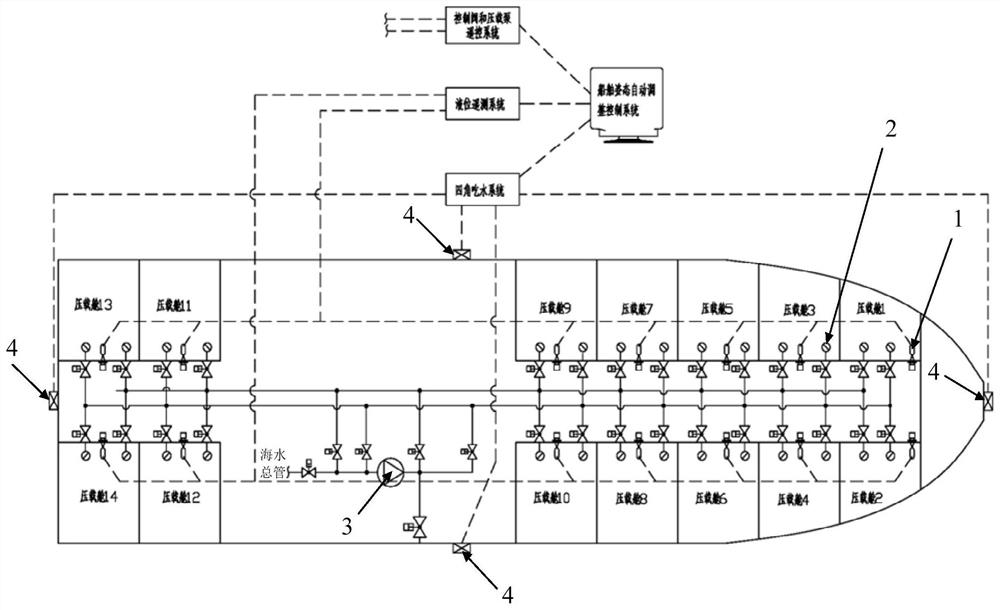

[0019] This application discloses a control method for automatic adjustment of ship attitude, please apply the method on ships, please refer to figure 1 As shown in the schematic diagram, there are several ballast tanks inside the ship, such as figure 1 14 ballast tanks are shown, and each ballast tank is generally symmetrically arranged relative to the ship's length direction. The arrangement position of each ballast tank, the total tank volume and the ballast water volume corresponding to the unit liquid level height are all known Yes, the calculation relationship between the internal liquid level state of the ballast tank and the ballast water volume can be determined according to the "Hull Capacity Calculation Sheet" provided at the design stage.

[0020] Each ballast tank is provided with a liquid level sensor 1, and each liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com