Vertical bin storage structure for chemical fertilizer

A fertilizer and storage technology, applied in chemical instruments and methods, containers, mixers, etc., can solve the problems of clogging of the discharge port of fertilizer, caking of fertilizer particles, and difficulty in outputting fertilizer, so as to avoid caking, improve full contact, Avoid the effect of clumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

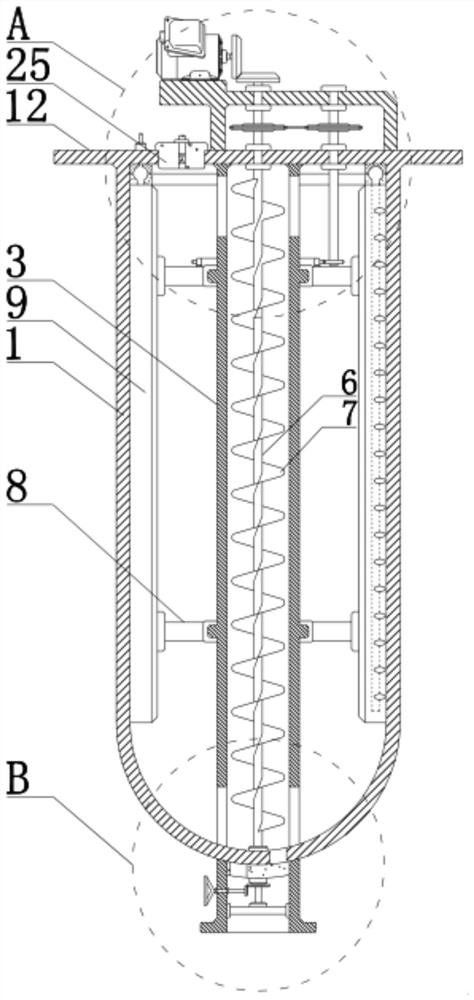

[0024] see Figure 1-3 , a vertical storage structure for chemical fertilizers, comprising a vertical warehouse body 1, a material turning mechanism, a scraping mechanism, and an air blowing mechanism, the vertical warehouse body 1 is vertically arranged, and the material turning mechanism, the scraping mechanism, and the blowing mechanism are all installed in the vertical warehouse The inner side of the body 1, and the turning mechanism and the scraping mechanism are both connected to the driving motor 2, and the driving motor 2 drives the returning mechanism and the scraping mechanism to move in the vertical bin body 1;

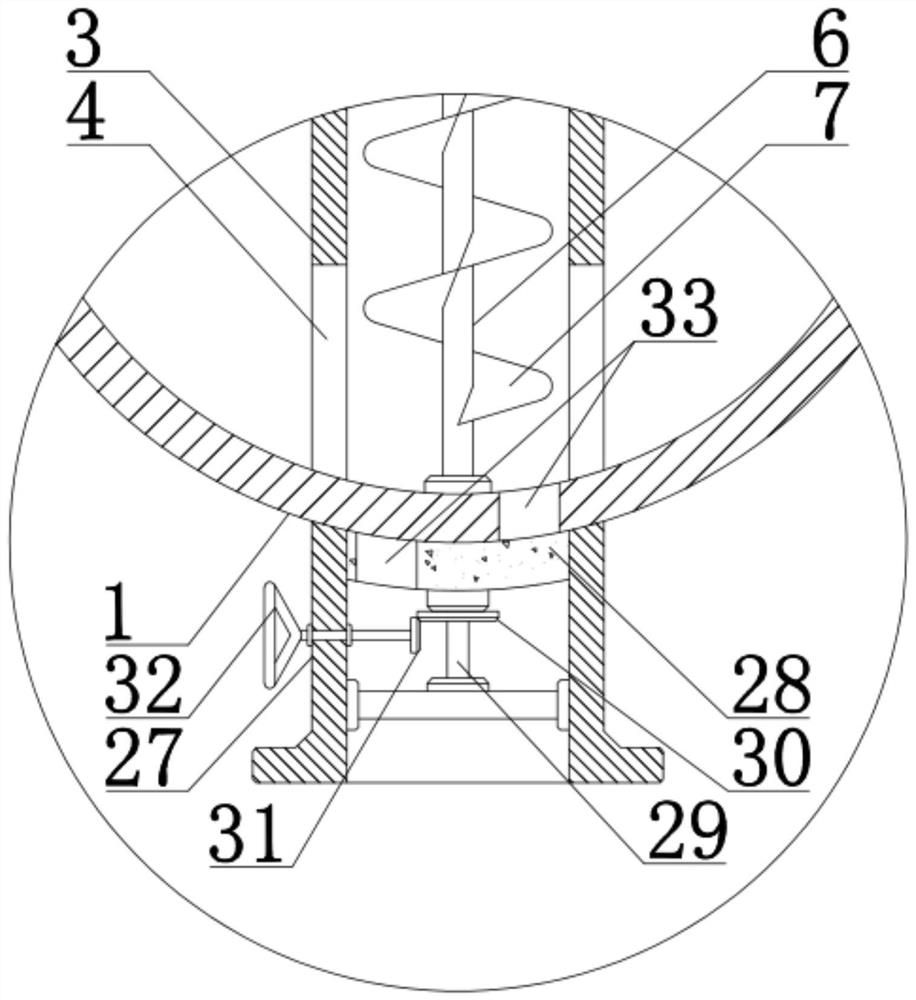

[0025] The material turning mechanism includes: the feeding pipe body 3 vertically consolidated in the vertical bin body 1 along the central position of the vertical bin body 1, the feed port 4 and the discharge port respectively provided at the bottom and top of the clinker pipe body. Port 5, the power shaft 6 that is nested and installed at the inner cent...

Embodiment 2

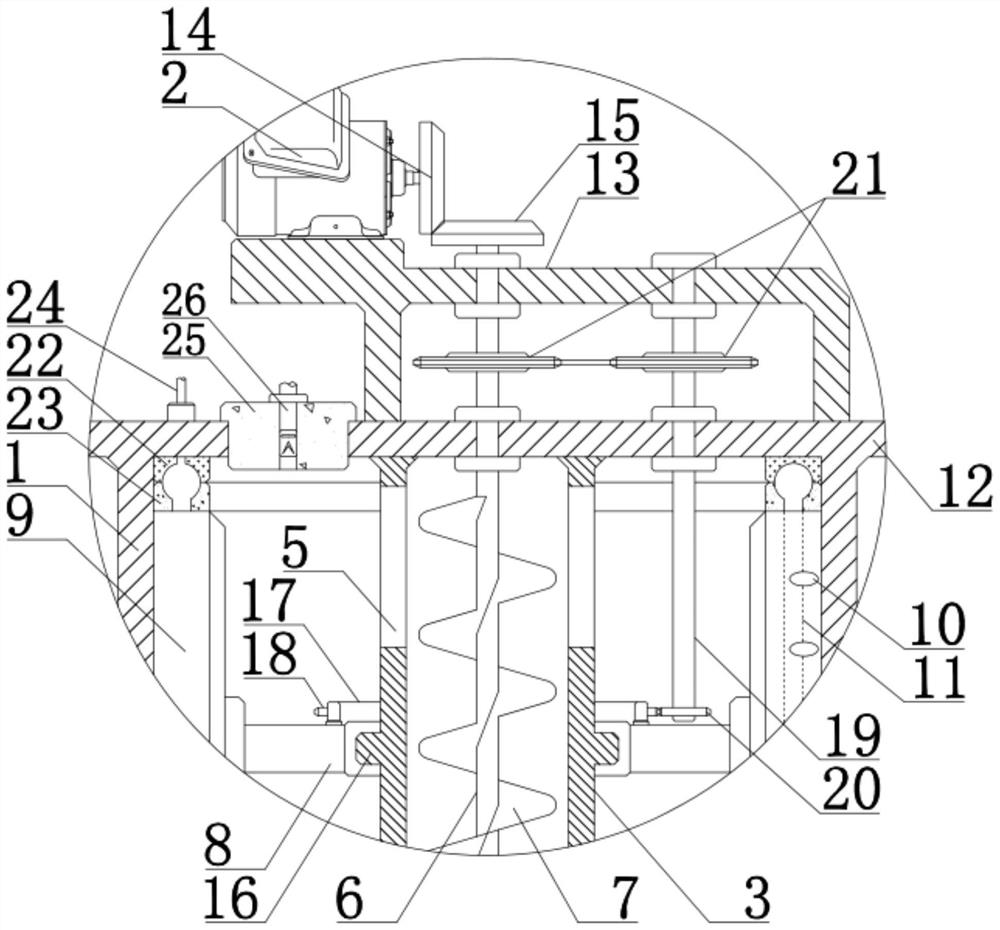

[0029] see Figure 1-2 , and according to Embodiment 1, the mode of power connection between the drive motor 2 and the power shaft 6 and the scraper 9 is described:

[0030] The top of the vertical warehouse body 1 is sealed and consolidated with a mounting plate 12, and a mounting bracket 13 is fixedly installed on the mounting plate 12, and the driving motor 2 is fixedly mounted on the mounting bracket 13, which ensures the stable installation of the driving motor 2 on the vertical warehouse body 1 The first reversing gear 14 is fixedly installed on the rotating shaft of the driving motor 2, the top of the power shaft 6 is passed out by the mounting plate 12, and the second reversing gear 15 is fixedly installed on the part of the power shaft 6 passing out of the mounting plate 12 The first reversing gear 14 is engaged with the second reversing gear 15, and the driving motor 2 drives the first reversing gear 14 to rotate, thereby driving the second reversing gear 15 and the ...

Embodiment 3

[0034] Please refer to 1-2, this article describes the communication mechanism in detail and technical supplements according to the embodiment 1-2. The opposite surfaces of the connecting ring body 22 and the second connecting ring body 23 are in close contact and keep relative rotation. The first connecting ring body 22 is fixedly installed on the lower surface of the mounting plate 12, and the second connecting ring body 23 is fixedly installed on each group of scrapers. The top of the plate 9, the contact surfaces of the first connecting ring body 22 and the second connecting ring body 23 are respectively provided with a first annular groove and a second annular groove, and the first annular groove is arranged on the lower surface of the first connecting ring body 22 and The air inlet pipe 24 is connected, and the air inlet pipe 24 is connected with the air source. The second annular groove is arranged on the upper surface of the second communicating ring body 23 and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com