Method and device for continuous extraction of crystalline magnesium in Pidgeon magnesium smelting process at high temperature

A technology of crystalline magnesium and high temperature, which is applied in the field of crystalline magnesium in the high-temperature continuous extraction Pidgeon method magnesium smelting process, which can solve the problems of large water consumption, non-continuous process, elevated temperature, etc., and achieve reduction of energy waste and mutual infiltration Small, big improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

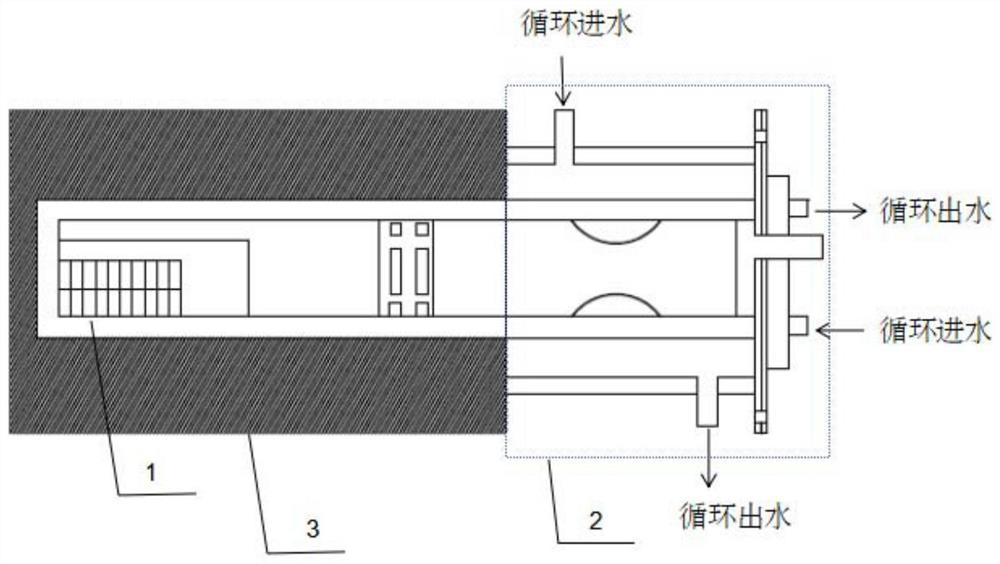

[0044] like figure 1 As shown, the present invention includes a reduction tank 1 arranged in the reduction furnace 3 and a magnesium crystallizer 2 communicated with the reduction tank 1 .

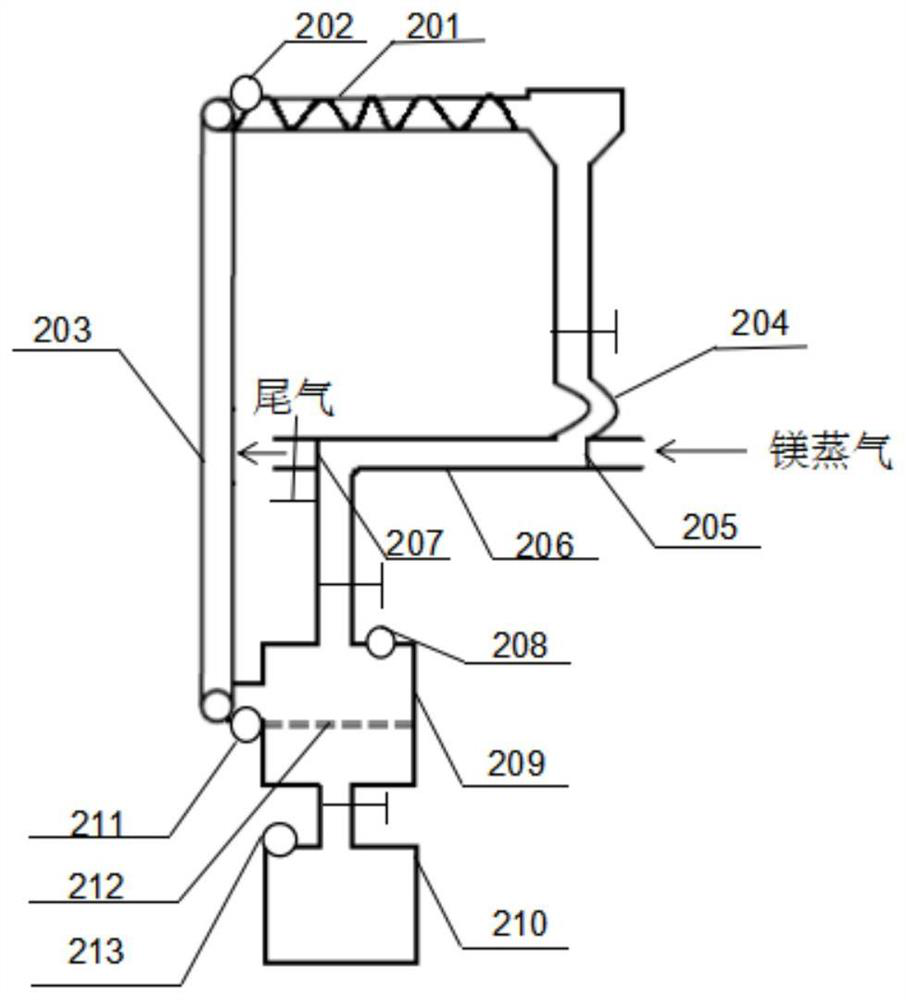

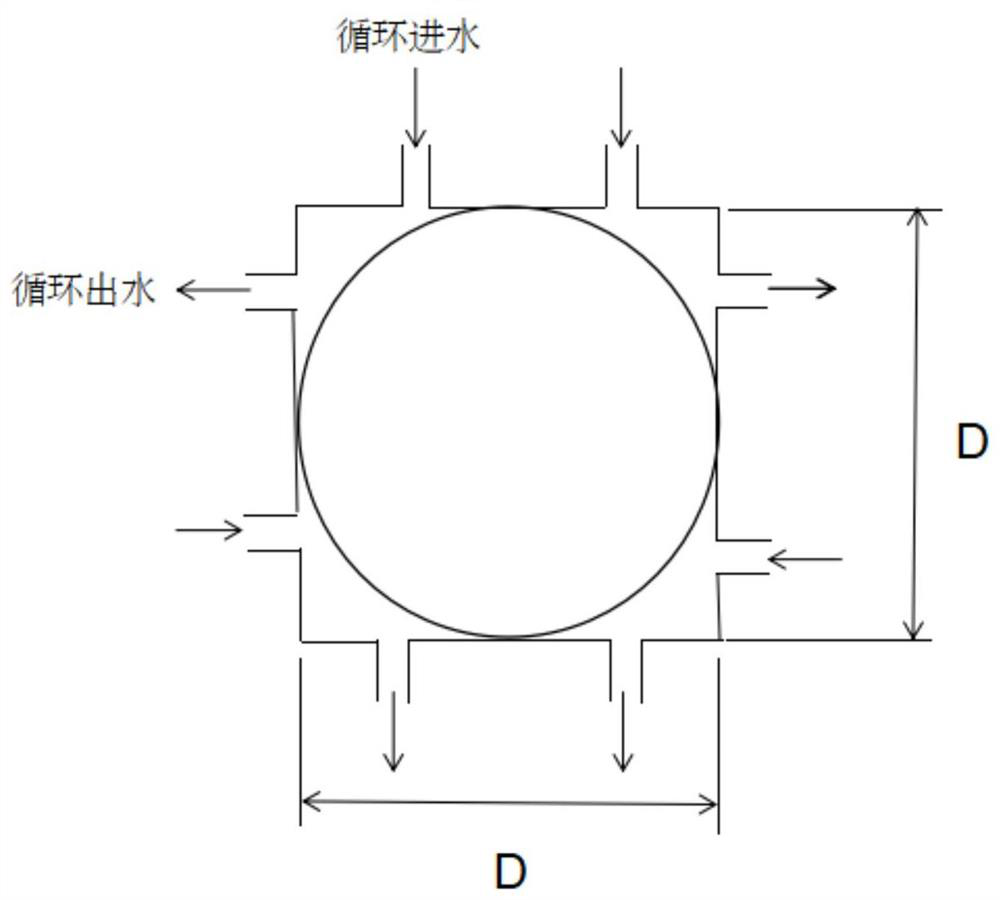

[0045] see figure 2 , the magnesium crystallizer 2 of the present invention includes a refining furnace 210 with a furnace mouth 213, and a ball material and a crystalline magnesium separator 209 communicated with the upper end of the refining furnace 210 is provided. The ball material and the crystalline magnesium separator 209 A porous screen 212 is installed inside, and the upper end of the porous screen 212 is provided with a circulating feeding device. The circulating feeding device includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com