Carbon fiber composite telescopic pipe and manufacturing method thereof

A technology of composite materials and manufacturing methods, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of low work efficiency, easy to be stuck, inconvenient operation, etc., and achieve high safety in use, wide range of use, Unlock handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings.

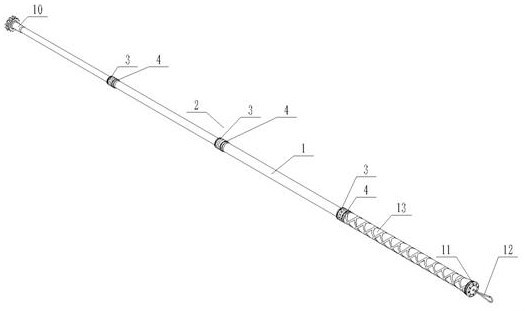

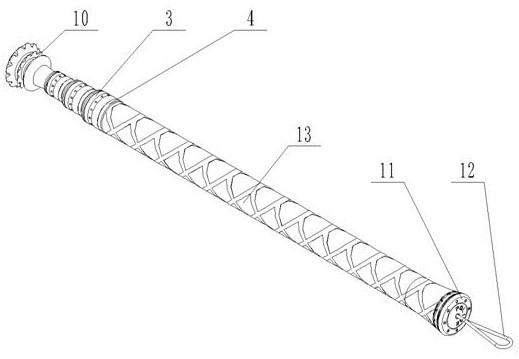

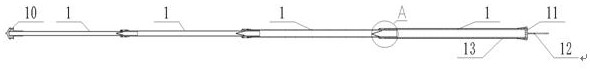

[0036] refer to Figure 1-Figure 6 , a carbon fiber composite telescopic tube and a manufacturing method thereof, comprising a multi-section sleeve 1 that can be telescopically arranged sequentially, and the outer diameter of each sleeve 1 decreases step by step from the outside to the inside, that is, the diameter of the outermost sleeve 1 is the largest , a protective sleeve 13 is set on the outer surface of the outermost casing 1 to improve the comfort of the user's grip, and anti-slip protrusions are processed on the surface of the protective sleeve 13 to prevent slipping during use and make it easier to be used Hold tight, the rear end of the outermost casing 1 is threaded with an anti-off ring 11, and a hole for installing a lanyard 12 is processed in the center of the anti-off ring 11, and the lan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com