Wall-climbing robot for receiving ballast water of ship

A technology for wall-climbing robots and ship ballast water, applied in the field of wall-climbing robots, can solve the problems of difficult reception and inconsistent interfaces, and achieve the effect of good promotion and application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

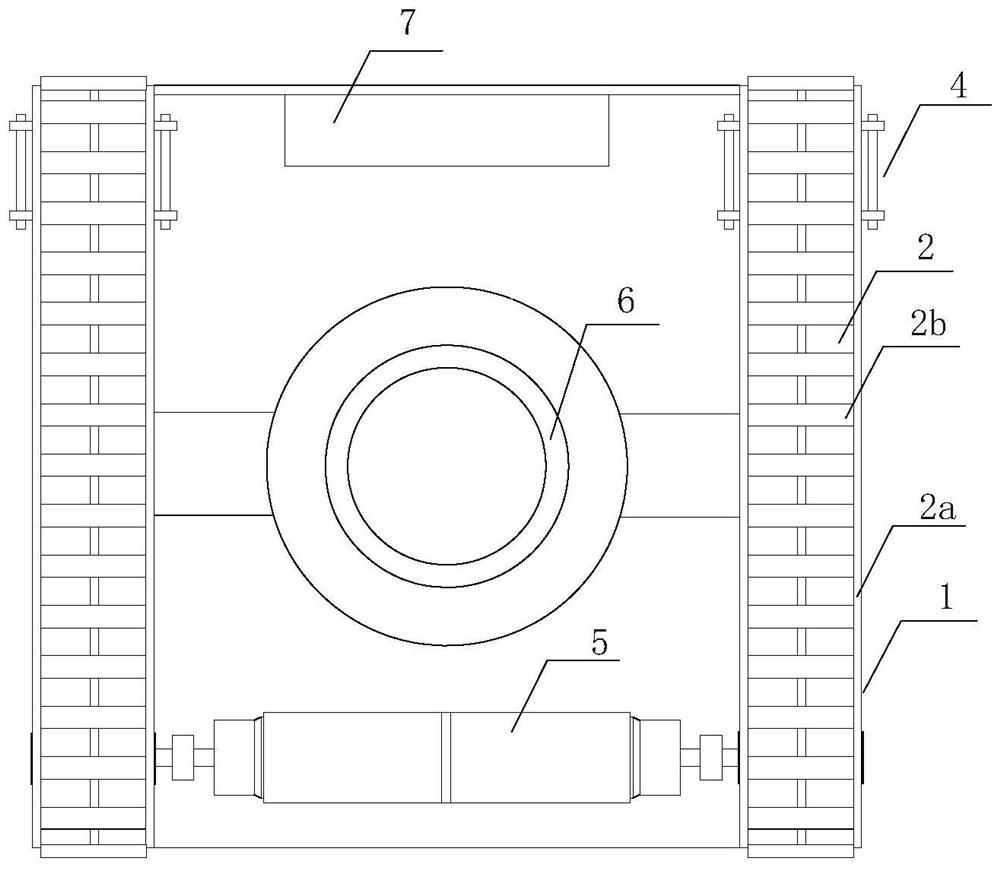

[0025] Such as figure 1 with figure 2 As shown, the wall-climbing robot for receiving ship ballast water includes a magnetic wall-climbing mechanism, a telescopic pipe joint and an electric control mechanism arranged on the mounting frame body 1; wherein,

[0026] The mounting frame body 1 is a cuboid sealed box body with a cavity inside, and the box body is provided with an upper cover that is easy to disassemble, so as to debug and overhaul before use; the mounting frame body 1 is made of non-magnetic metal (such as stainless steel) )production;

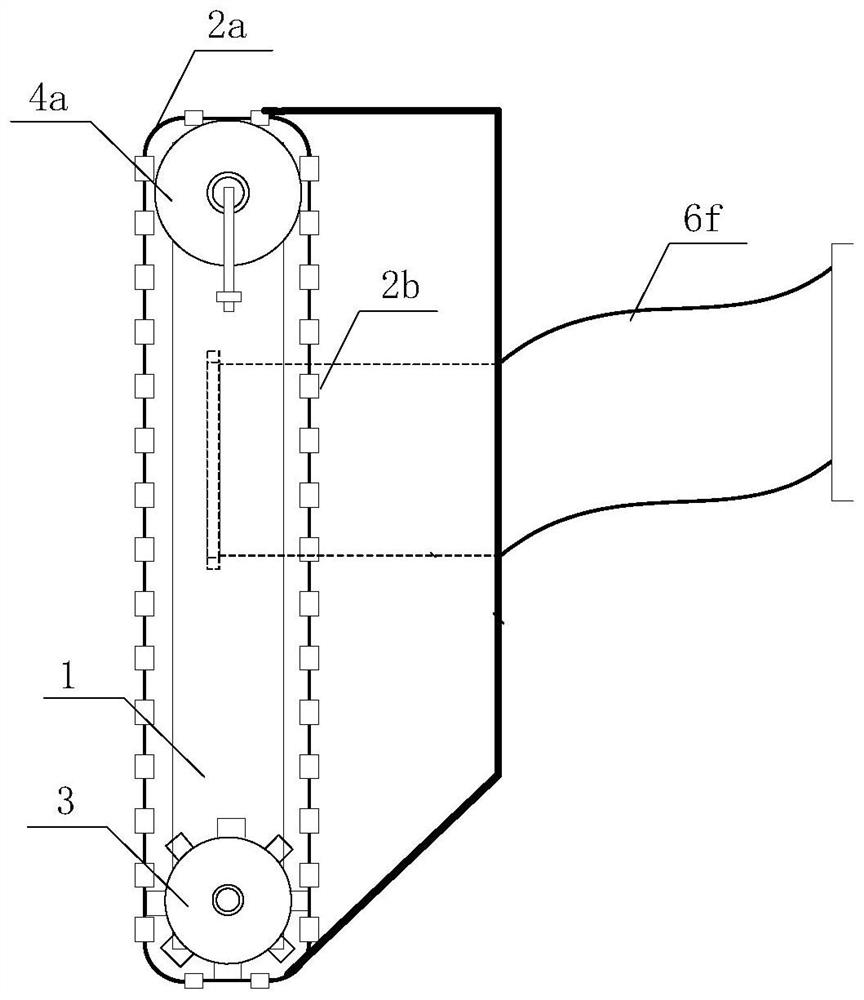

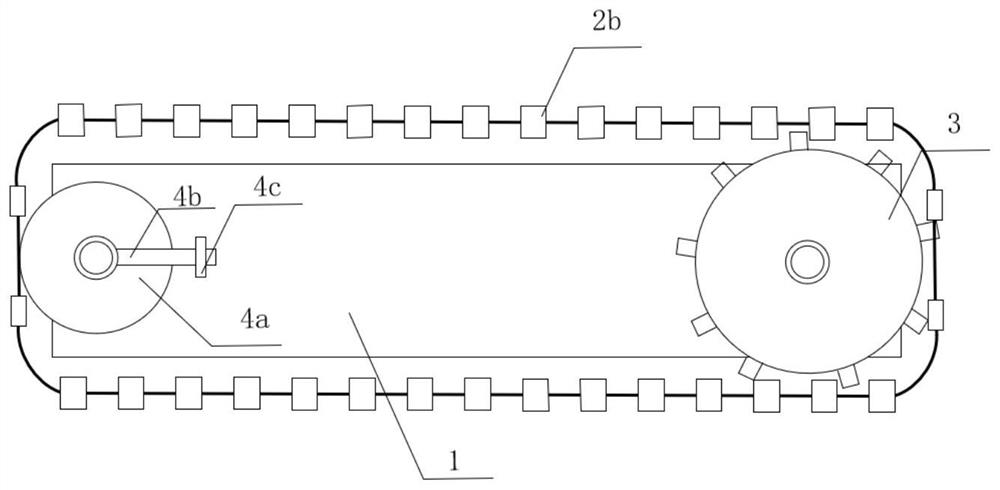

[0027] Such as image 3 As shown, the magnetic wall climbing mechanism includes two sets of moving mechanisms symmetrically arranged on the left and right side walls of the mounting frame body 1 and two drive motors 5 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com