Auxiliary oil return control method of multi-split air conditioner, auxiliary oil return device of compressor and multi-split air conditioner

An oil return control, multi-connection technology, applied in compressors, control inputs involving air characteristics, heating and ventilation control systems, etc., can solve problems such as slow oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

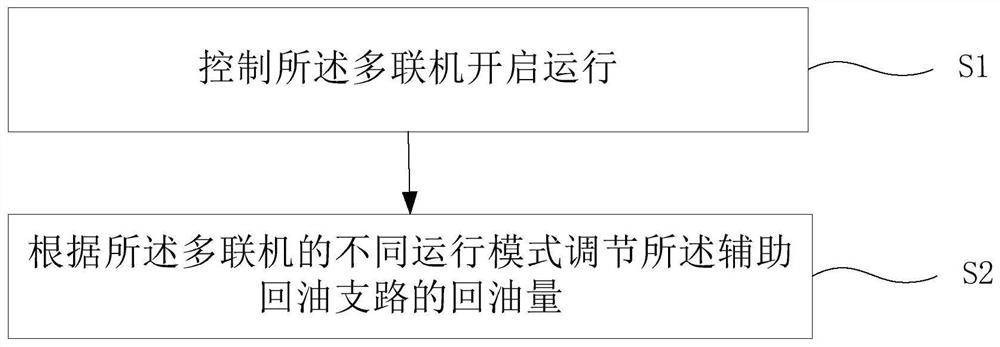

[0038] see figure 2 , which is a schematic flowchart of a multi-line auxiliary oil return control method provided in Embodiment 1 of the present invention. The multi-line includes a compressor 10, an auxiliary oil return branch 30 and a gas-liquid separator 40; wherein the auxiliary oil return branch 30 is connected between the compressor 10 and the gas-liquid separator 40, combined Figure 3-Figure 4 , the auxiliary oil return control method includes, for example:

[0039] S1: controlling the multi-connection to start and run;

[0040] S2: Adjust the oil return volume of the auxiliary oil return branch (30) according to the different operation modes of the multi-line.

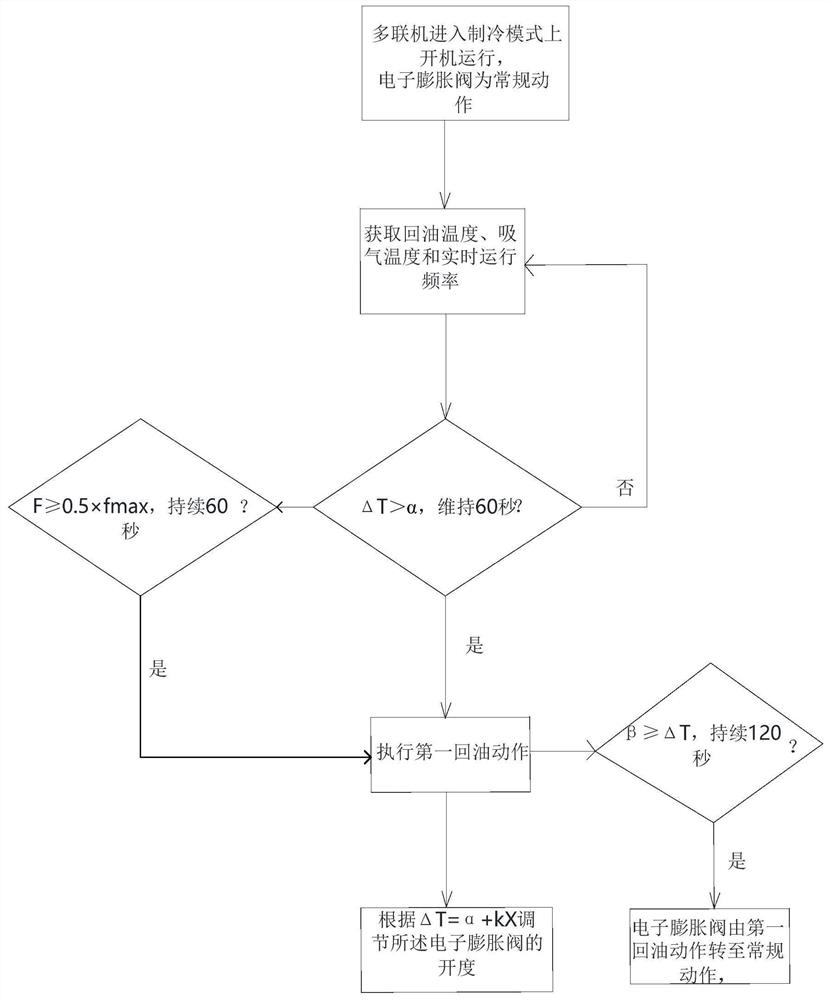

[0041] Preferably, the auxiliary oil return control method includes, for example: obtaining the real-time operating frequency of the compressor 10, the suction temperature of the compressor 10, the oil return temperature of the auxiliary oil return branch 30, and the relationship between the suction tempera...

Embodiment 2

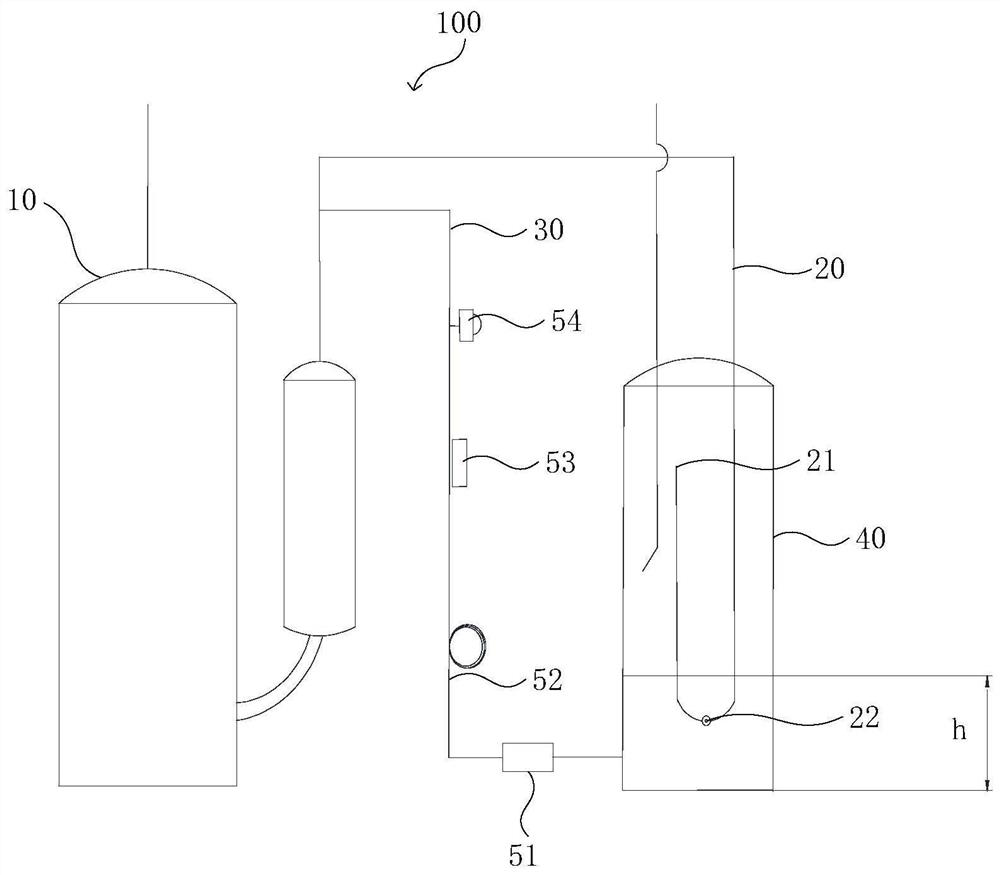

[0058] see figure 1 , which is a schematic connection diagram of a compressor auxiliary oil return device 100 provided in Embodiment 2 of the present invention. The compressor auxiliary oil return device 100 includes, for example, a compressor 10, a gas-liquid separator 40 and an air return pipeline 20. The air return pipeline 20 is used to connect the compressor 10 and the gas-liquid separator 40, so that it is stored in the gas-liquid separator 40 The lubricating oil is returned to the compressor 10 through the air return pipeline 20, so that the compressor 10 can be supplemented by returning oil during operation.

[0059] In a specific embodiment, combined with the actual operating conditions of the compressor 10, generally, the lubricating oil will be discharged from the output end of the compressor 10 and recirculated back to the input end of the compressor. Specifically, when the multi-line When the control is operated at a low frequency, it will lead to slow oil return...

Embodiment 3

[0066] Embodiment 3 of the present invention provides a multi-connection unit, which can run the auxiliary oil return control method as described in the first embodiment above; or, the multi-connection unit includes the compressor auxiliary oil return control method as described in the second embodiment above. Oil unit 100.

[0067] Preferably, an auxiliary oil return assembly is provided on the auxiliary oil return branch 30 , wherein the auxiliary oil return assembly is used to control and adjust the opening of the oil return opening of the auxiliary oil return branch 30 .

[0068] For example, in combination with the actual oil return situation, when the amount of oil returned from the air return pipeline 20 to the compressor 10 is sufficient, the opening of the oil return opening can be closed or kept at a small opening; otherwise , then increase the opening of the oil return opening, so that the auxiliary oil return branch 30 plays the role of auxiliary oil return, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com