Independent flow online detection and verification method for parallel equipment of refrigeration station

A refrigeration station and equipment technology, applied in the direction of mechanical equipment, lighting and heating equipment, heating methods, etc., can solve problems such as wrong analysis conclusions, unrealistic flowmeters, and insufficient length of straight pipes required for normal installation of common flowmeters, etc., to achieve The effect of low cost and easy on-site implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

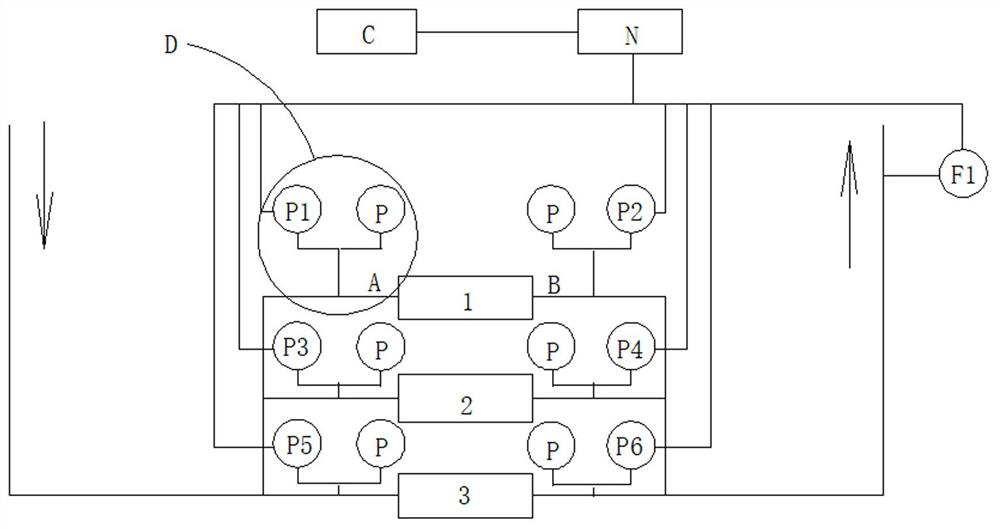

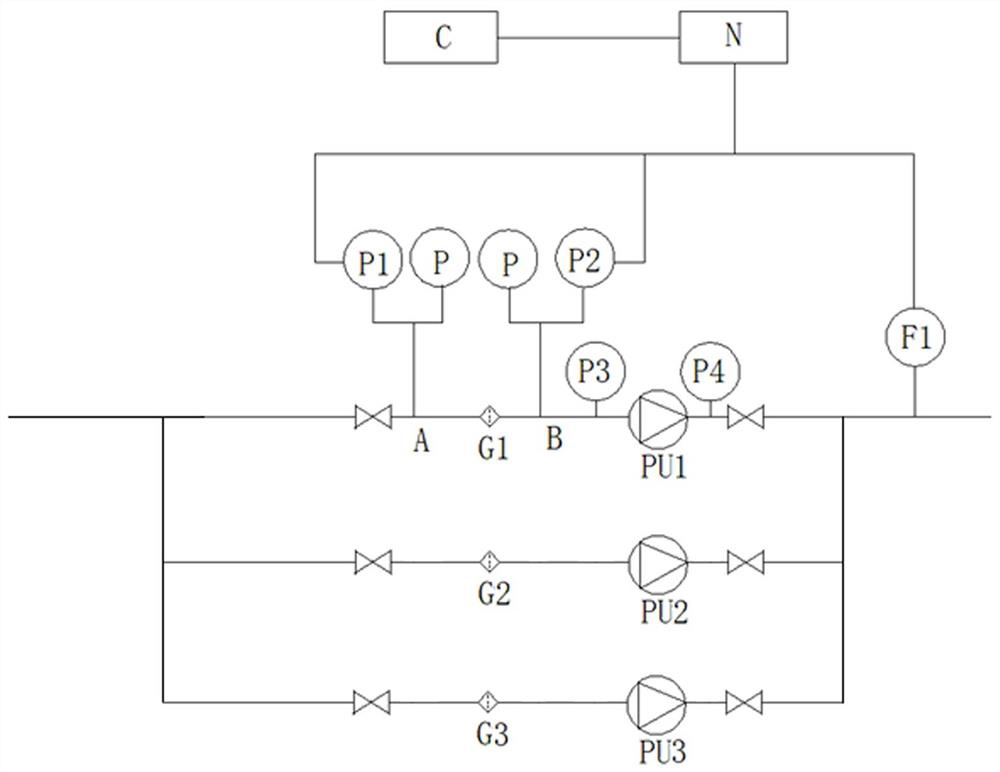

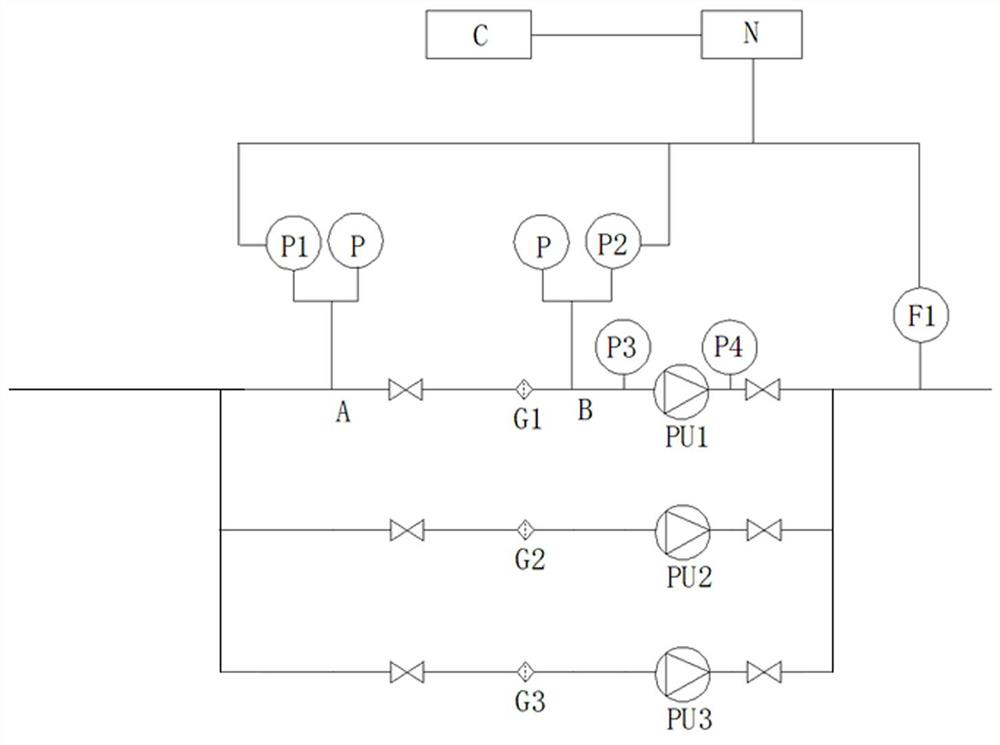

[0081] See attached figure 1 , 3 , independent flow online detection of parallel equipment in freezing stations:

[0082] In the parallel air-conditioning water system equipment, it includes a plurality of parallel resistance devices 1 to 3, main pipe flowmeter F1, data collector N, processor and memory C, main pipe flowmeter F1 inputs the flow data of the main pipe into the data collector N and processor and memory C; also includes the pipeline composed of pressure sensors P1, P2, inspection valve JV, annular buffer bend H, tee joint XT and connecting pipe, and the upstream and downstream straight pipe sections A and B of the resistance equipment are processed Install the pressure-taking pipe G, set the maintenance valve JV and the annular buffer bend H on the pressure-taking pipe G, connect a three-way joint XT at the end of each pressure-taking pipe G, and the other two interfaces of each three-way joint XT respectively Connect to ordinary pressure gauge (for on-site indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com