Steel box girder bending performance detection device for road and bridge construction

A detection device, the technology of steel box girder, which is applied in the direction of measuring device, using stable bending force to test the strength of materials, bridges, etc., can solve the problems of increasing construction cost and time cost, increasing construction cost and time cost, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

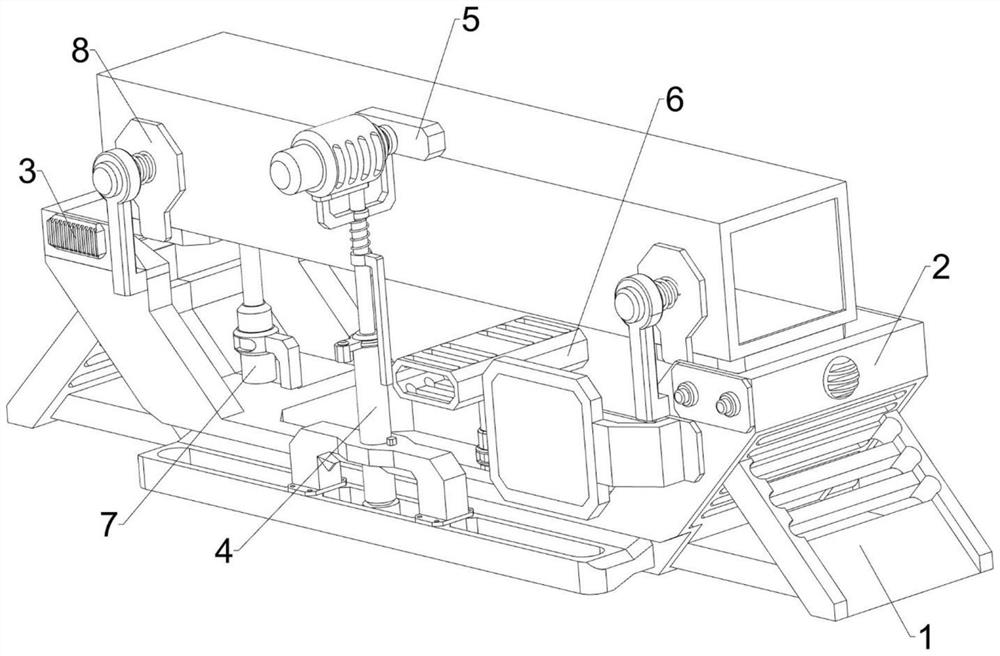

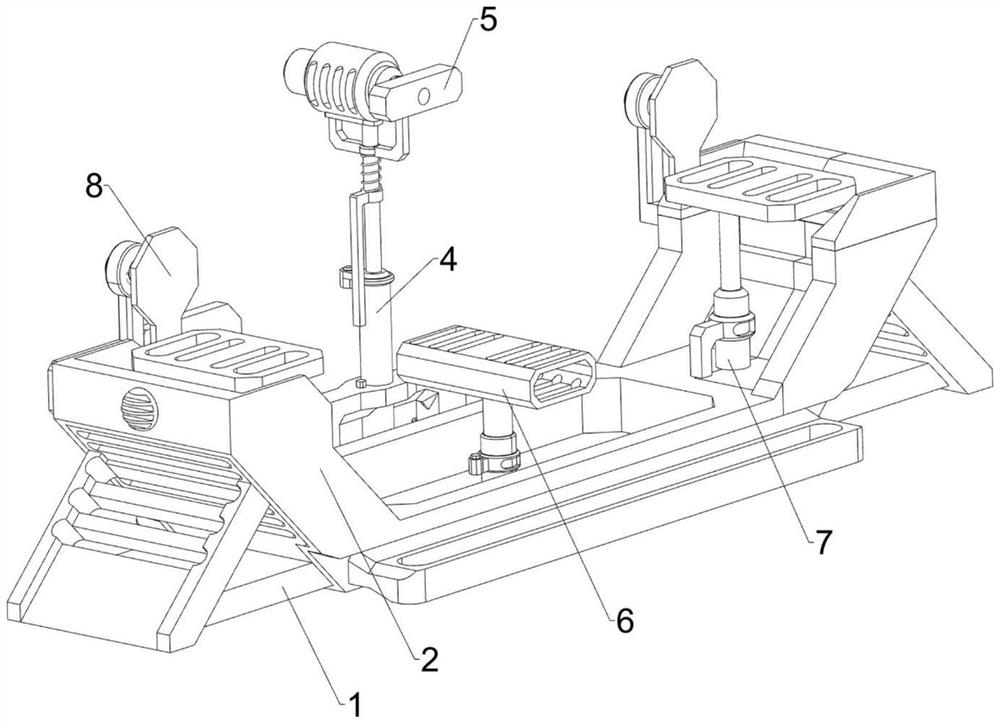

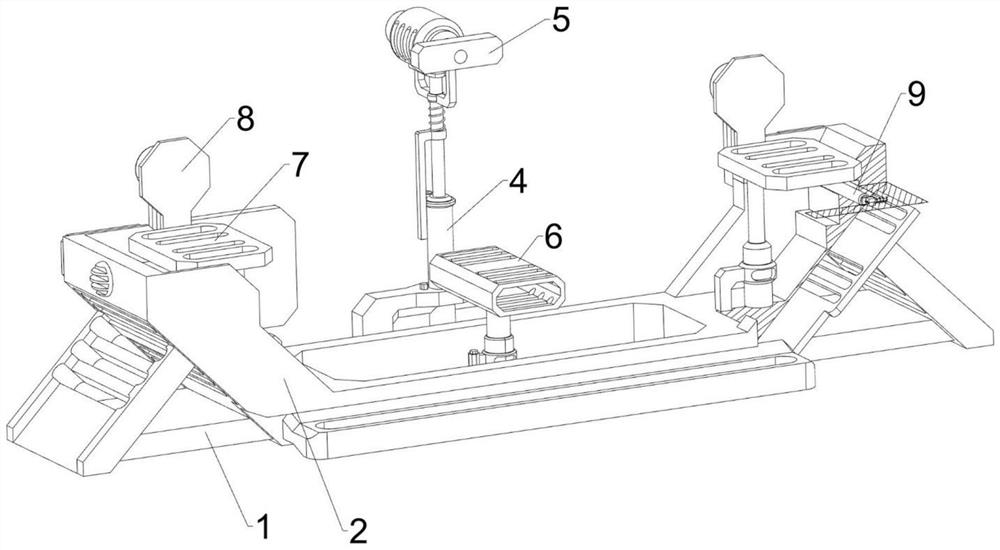

[0036] Embodiment: A bending performance detection device for steel box girders used in road and bridge construction.

[0037] refer to Figure 1-Figure 7 As shown, it includes a connection seat 1, a frame 2, a start switch 31, a reset switch 32, a telescopic assembly 4 and a pressure test assembly 5. A telescopic assembly 4 is provided on the front side of the bottom, and a pressure test assembly 5 is provided between the telescopic assembly 4 and the frame 2. A start switch 31 and a reset switch 32 are fixedly connected to the upper right side of the outer front side of the frame 2, and the start switch 31 is located at the reset position. Switch 32 to the right.

[0038] The telescopic assembly 4 includes a first electric push rod 43, a connecting sleeve 44 and a first distance sensor 45. The first electric push rod 43 is fixedly connected in the middle of the front side of the inner bottom of the frame 2, and the upper part of the first electric push rod 43 is fixed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com