Test equipment for detection of anti-collision performance of shell of energy automobile

A technology of automobile casing and test equipment, applied in the direction of measuring device, strength characteristics, instrument, etc., can solve the problems of cylinder damage, reducing impact energy of impact hammer, and failing to meet impact test requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

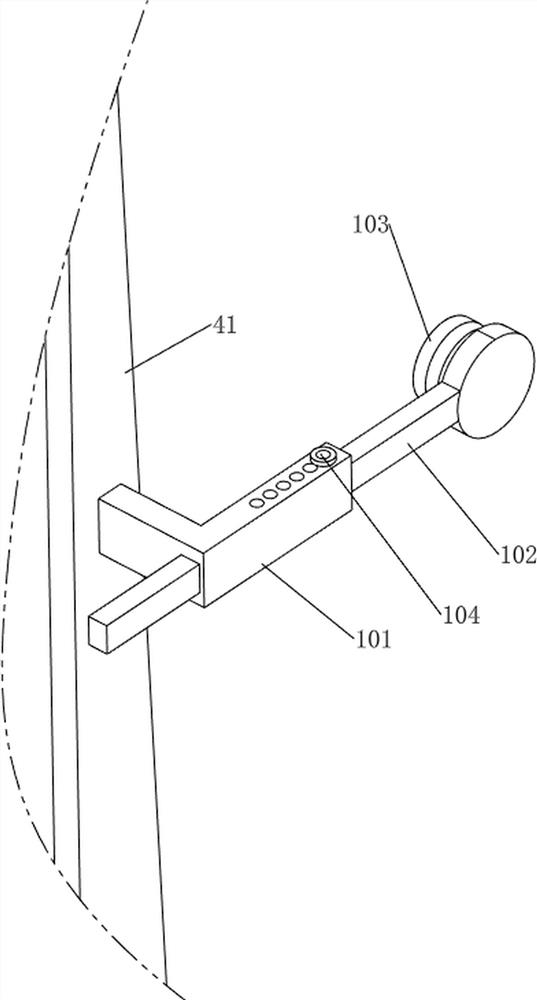

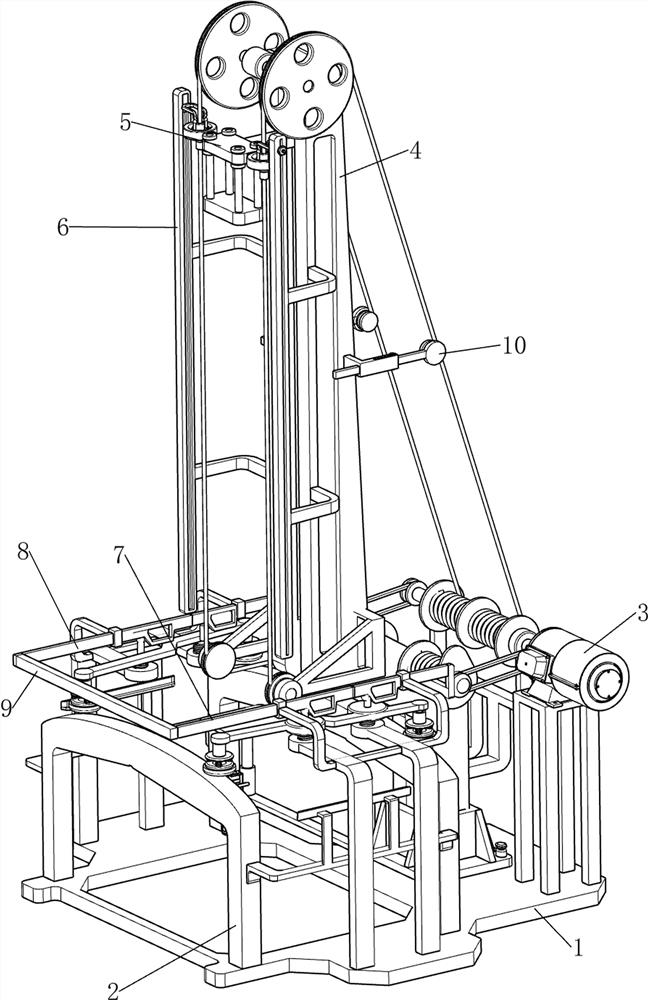

[0027] A test equipment for testing the anti-collision performance of the shell of targeted energy vehicles, such as Figure 1-4 As shown, it includes a base 1, a supporting platform 2, a motor 3, a pulling mechanism 4 and a pressing mechanism 5, the left side of the base 1 is provided with a supporting platform 2, the right front side of the base 1 is provided with a motor 3, and the output shaft of the base 1 and the motor 3 Pulling mechanism 4 is arranged between, and pulling mechanism 4 is provided with pressing mechanism 5, and pressing mechanism 5 comprises first sliding block 51, pressing block 52, pulling block 53, clamping block 54 and telescopic rod 55, pulls The parts of the mechanism 4 are slidably connected with a first sliding block 51, the bottom of the first sliding block 51 is provided with a detachable lower pressing block 52, and the parts of the pulling mechanism 4 are all provided with a pulling block 53, the front and rear of the first sliding block 51 Tw...

Embodiment 2

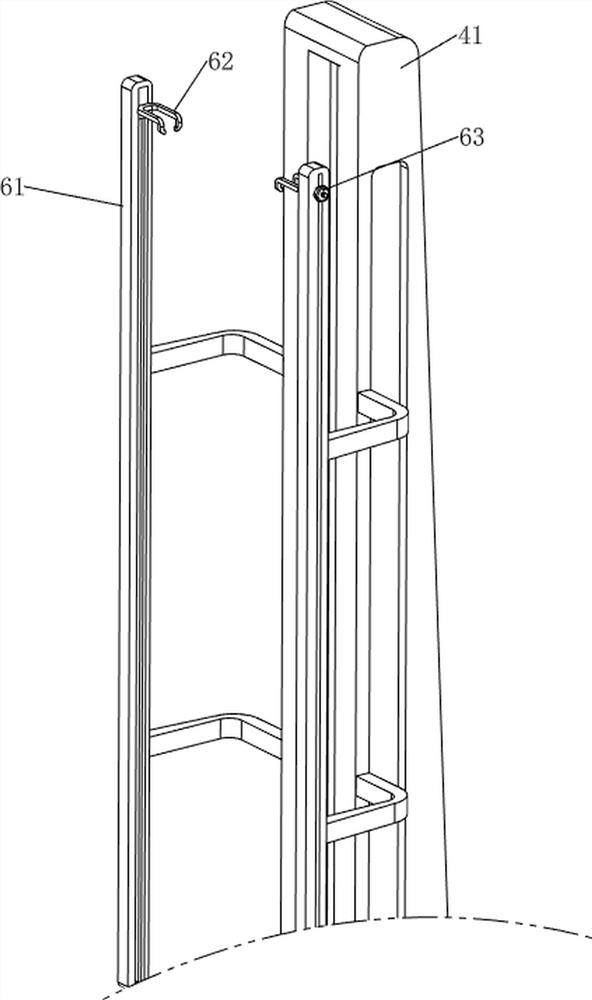

[0031] On the basis of Example 1, such as Figure 5-9 As shown, the distance adjustment mechanism 6 is also included, and the distance adjustment mechanism 6 includes a fixed rod 61, a second sliding block 62 and a fixed bolt 63. A second sliding block 62 is connected in a sliding manner, and a fixing bolt 63 is threadedly connected to the outside of the second sliding block 62 .

[0032] According to the degree of detection of the car shell, the fixing bolt 63 can be removed first, and then the second sliding block 62 can be moved up and down so that the second sliding block 62 can be moved to a suitable position, and then the fixing bolt 63 can be rotated and reset so that the second sliding block The block 62 is fixed, so that the height of the upward movement of the lower pressing block 52 can be adjusted. When the locking block 54 moves upwards and contacts the second sliding block 62, the locking block 54 is moved to the outside, and the lower pressing block 52 is moved do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com