Full-automatic double-end processing equipment for data line

A processing equipment, fully automatic technology, applied in the direction of circuit/collector parts, electrical components, circuits, etc., can solve the problems of easy operation, low product quality, affecting the stripping accuracy, etc., to avoid the welding position. Correct, high degree of automation, realize the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

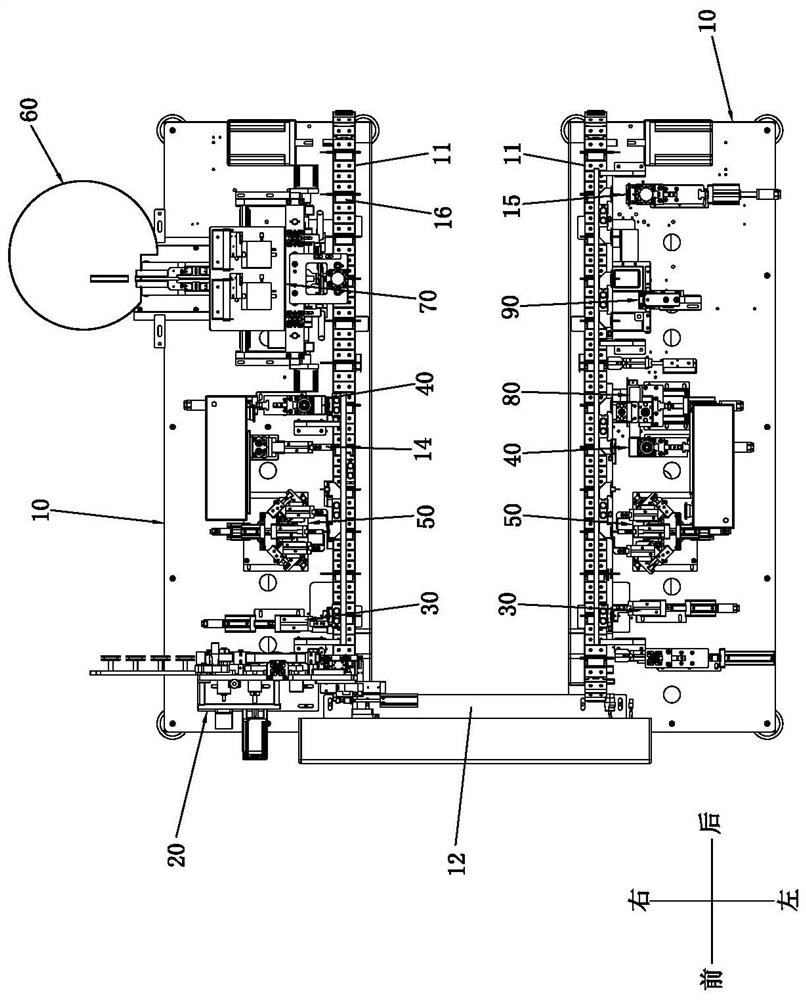

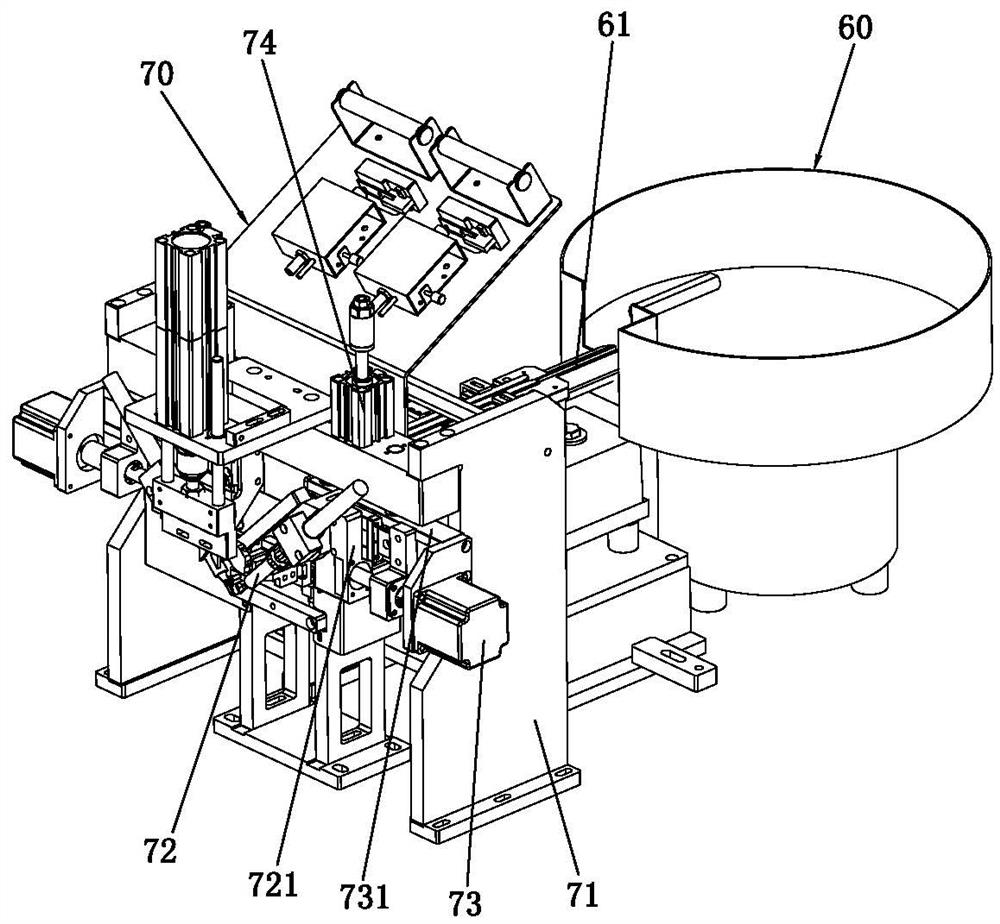

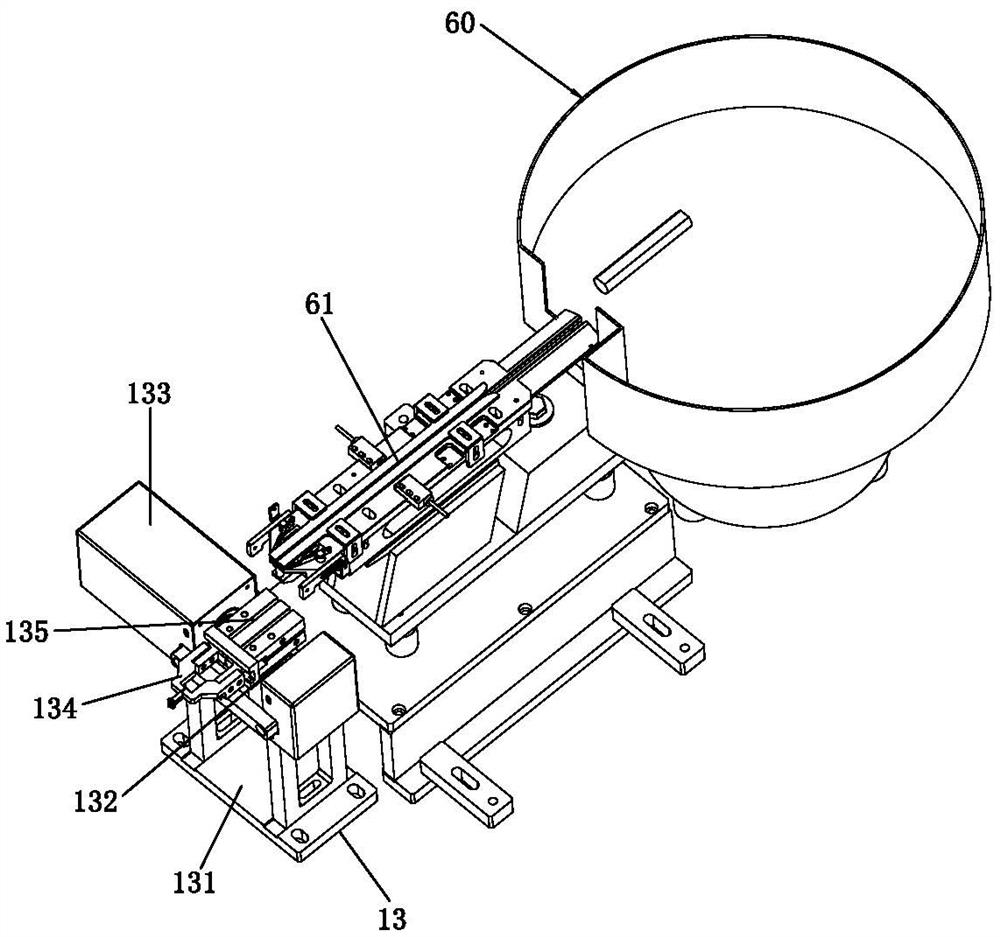

[0056] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the embodiment of the present invention.

[0057] A fully automatic double-head processing equipment for data wires, which is suitable for processing data wires with two or more core wires, including an organism 10, a wire feeding mechanism 20 for conveying wires, and a device for peeling wires The first stripping mechanism 30, the second stripping mechanism 40 for stripping the core wire, the line whole mechanism 50 for leveling the core wire and adjusting the position, the joint feeding mechanism 60 for transporting the joint, and the joint feeding mechanism 60 for connecting the joint with the The welding mechanism 70 for core wire welding, the twisting mechanism 80 for twisting the core wire, and the processing mechanism 90 for tinning the core wire; wherein: the body 10 is provided with two parallel arrangements, Both bodies 10 are provided with conveying mechanisms 11 for conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com