Electromagnetic heating structure for rapid heating and cooling of thin-wall pot body

A heating structure, heating and cooling technology, applied in heating devices, cooking utensils, household appliances, etc., can solve problems such as unfavorable heating of the heating pot, heating of the heating pot body, inconvenient access and cleaning, etc. The effect of reducing heat waste and facilitating temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

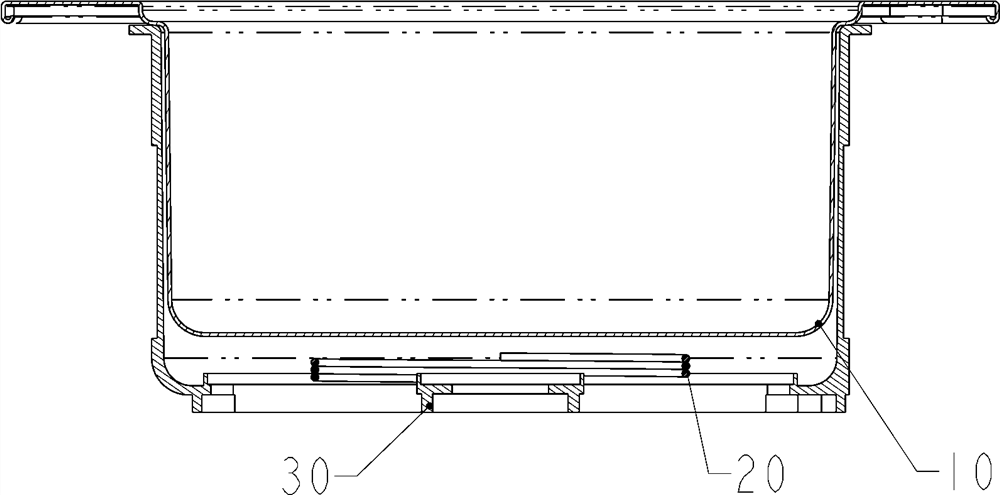

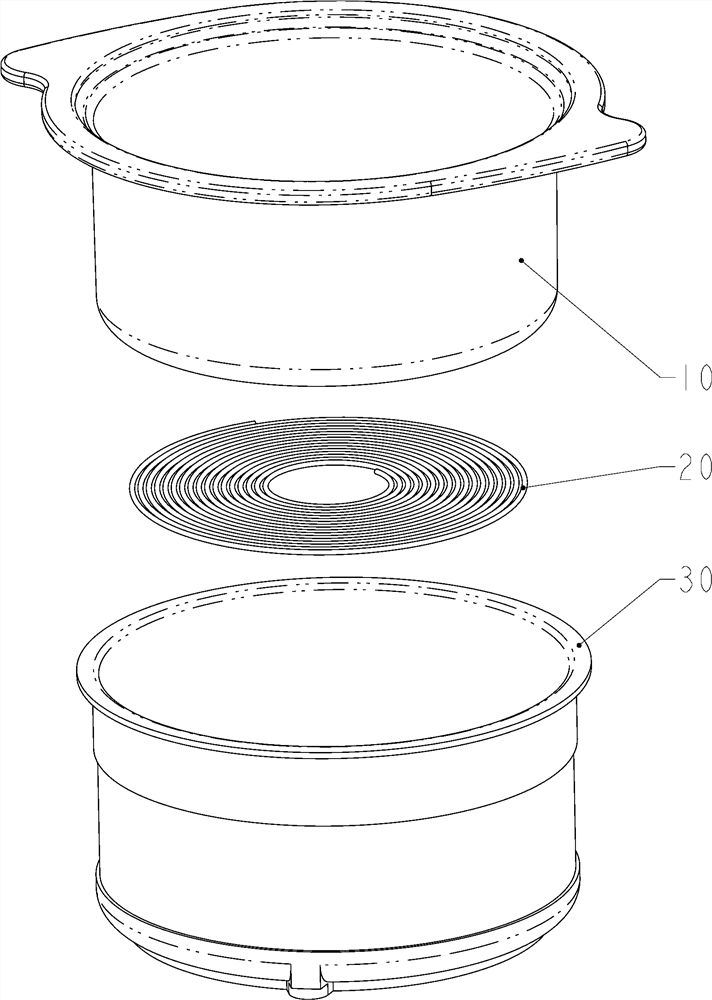

[0042] Implementation method 1: if figure 1 , figure 2 As shown, the coil 20 is placed under the bottom of the thin-walled heating pot 10 , and the bracket 30 connects and fixes the coil 20 and the thin-walled heating pot 10 together.

[0043] Further, the maximum diameter of the coil 20 is smaller than the maximum outer diameter of the bottom of the thin-walled heating pot 10 , and the minimum diameter of the coil 20 is greater than 0.001 times the maximum outer diameter of the bottom of the thin-walled heating pot 10 .

[0044] Furthermore, when the coil 20 generates an alternating magnetic field, the bottom of the thin-walled heating pot 10 corresponding to the coil will generate current to generate self-heating, and this self-heating area is related to the size of the coil, such as Figure 5 As shown, the highest temperature region is larger than the largest diameter A of the coil 20 and smaller than the smallest diameter B of the coil 20 .

[0045] Furthermore, during ...

Embodiment approach 2

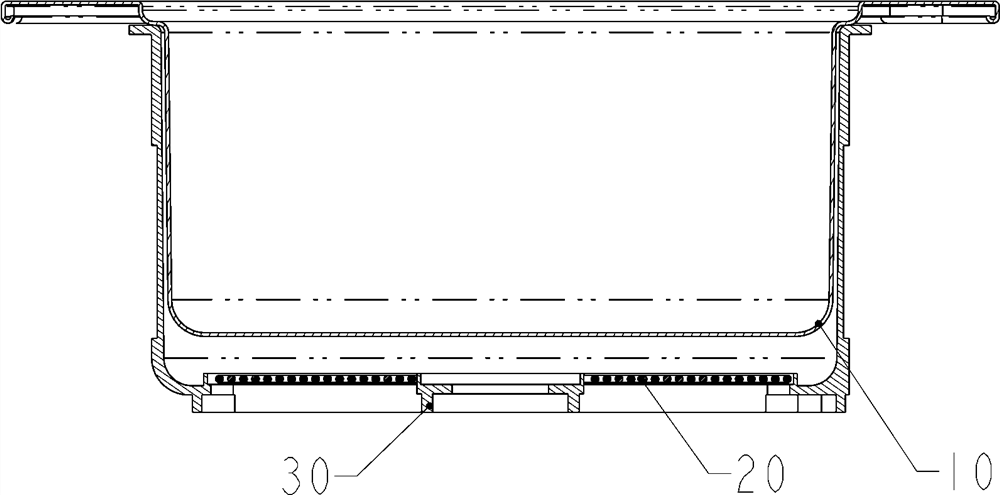

[0050] Implementation method 2: if image 3 , Figure 4 As shown, the coil 20 is not only placed under the bottom of the thin-walled heating pot 10, but also placed outside the vertical wall of the thin-walled heating pot 10, and the bracket 30 connects and fixes the coil 20 and the thin-walled heating pot 10 together.

[0051] Further, the coil 20 on the outside of the vertical wall of the thin-walled heating pot 10 and the coil 20 at the bottom of the thin-walled heating pot 10 generate an alternating magnetic field to heat the thin-walled heating pot 10 to achieve the effect of implementing method 1. The outermost layer of the vertical wall of 10 is as Figure 6 A high-temperature region is generated as shown in middle E, and the heat of this part is transferred to the inner wall of the thin-walled heating pot 10 through the thin wall of the thin-walled heating pot 10 for heating food materials.

[0052] Further, there are many thin-walled heating pots 10 in Embodiment 2 ...

Embodiment approach 3

[0054] Implementation method 3: if Figure 7 As shown, the coil 20 is wound in the shape of a spring, and its effect is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com