Vibration flocking tool

A tooling and flocking technology, which is applied in the field of vibrating flocking tooling, can solve problems such as insufficient flocking and uneven flocking, and achieve the effect of fast clamping and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

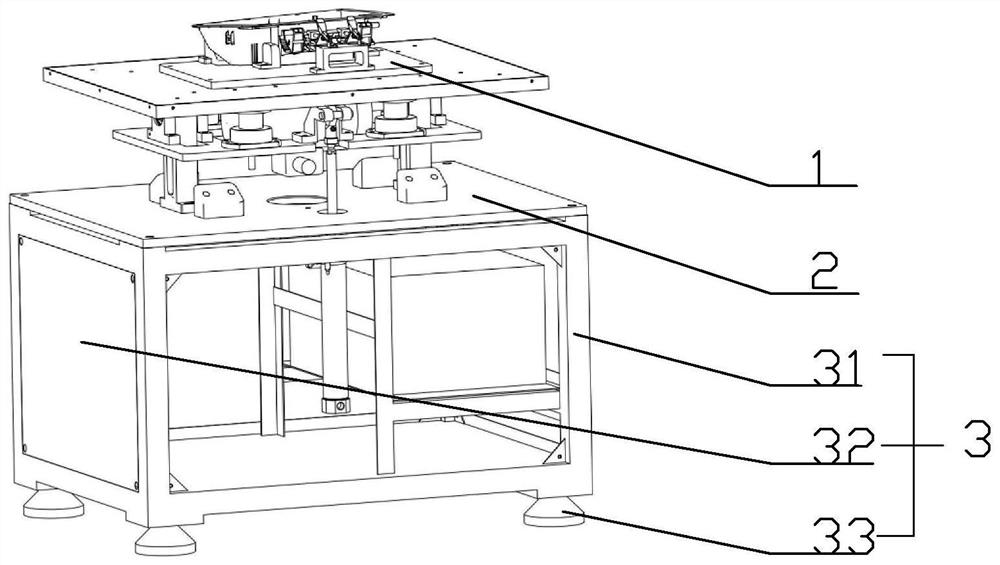

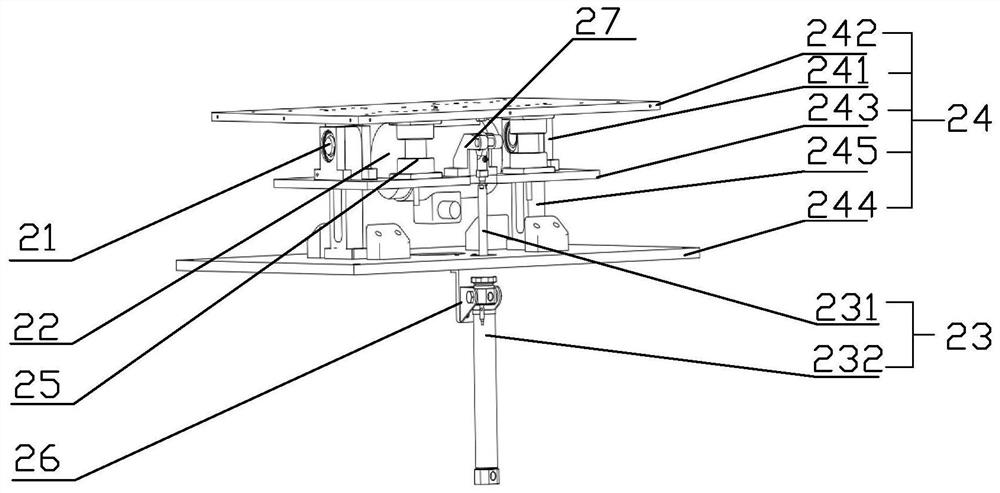

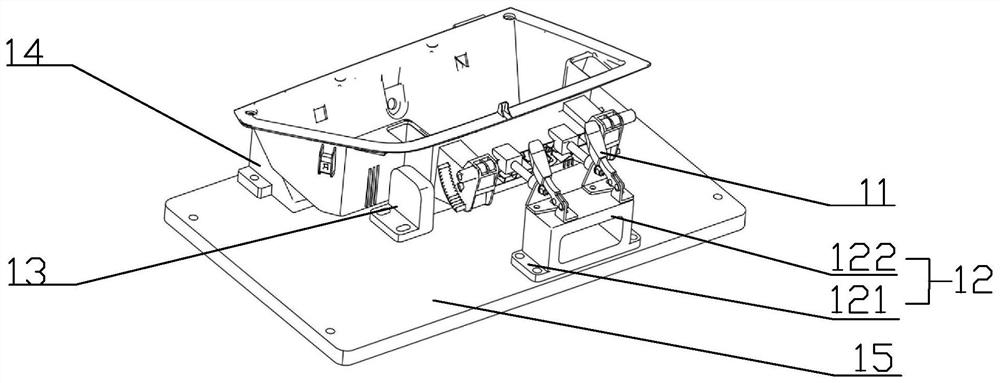

[0039] Such as figure 1 and figure 2 As shown, a vibrating flocking tooling includes a vibrating mechanism 1 and an overturning stand 2 arranged below the vibrating mechanism 1. The overturning stand 2 includes a stand body 24 and two turning bearings 21 arranged on the stand body 24. , the vibrating motor 22 arranged between the two reversing bearings 21 and the reversing cylinder 23 arranged below the vibrating motor 22 , the reversing cylinder 23 is connected to the stand body 24 .

[0040] The overturning bearing is used to drive the vibration mechanism overturning when the overturning table is overturned, so that the product is turned over at an angle so that the classic fluff can better contact the inner wall of the product. The vibration motor drives the vibration mechanism to vibrate in the form of vibration, and the high flat rate o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com