Bending machine for a plate welding seam

A bending machine and plate technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of non-conformity and inability to realize repeated bending of welds, achieve simple structure, improve detection accuracy, Ease of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

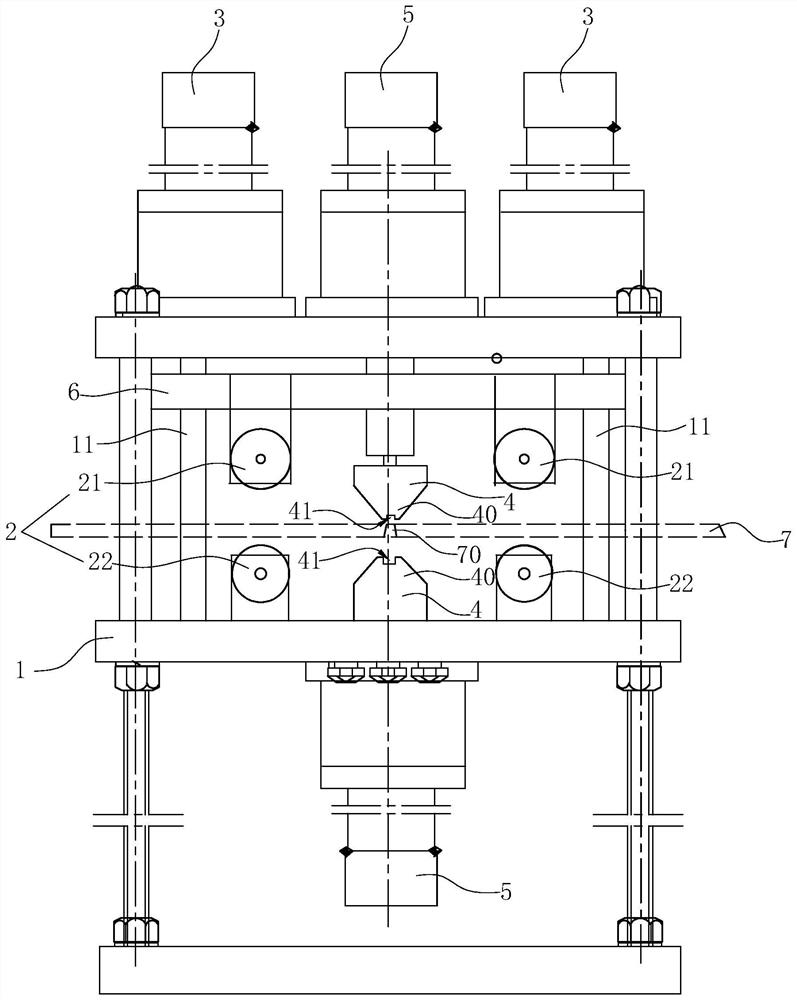

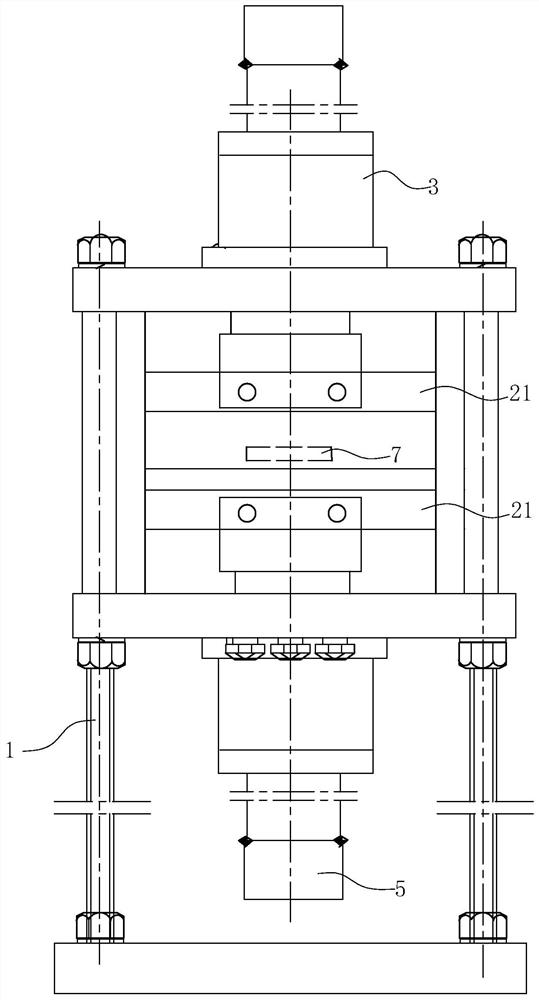

[0028] Such as figure 1 , 2 As shown, it is a preferred embodiment of a bending machine for welding seams of plates according to the present invention. Drive 5.

[0029] Wherein, the bottom of the frame 1 is provided with casters for supporting the frame 1 (the casters are not shown in the figure, the casters are designed with reference to existing structures, such as adopting existing universal wheels, etc.). The casters have four and are arranged on the four corners of the bottom of the frame 1 .

[0030] Two pressure rollers (respectively being the first pressure roller 21 and the second pressure roller 22) are used as a group, and the pressure roller 2 has two groups and is arranged side by side along the horizontal direction at intervals. In each group, the first pressure roller 21 and the second pressure roller The pressing rollers 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com