Indexable forming gear milling cutter head device

A tooth milling and cutter head technology, which is applied in the fields of high-efficiency roughing milling cutters and forming tooth milling cutter heads, can solve problems such as strength damage, hidden dangers to worker safety, and slow down the gear manufacturing process, so as to achieve extended service life and chip removal rate High, the effect of avoiding heat deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

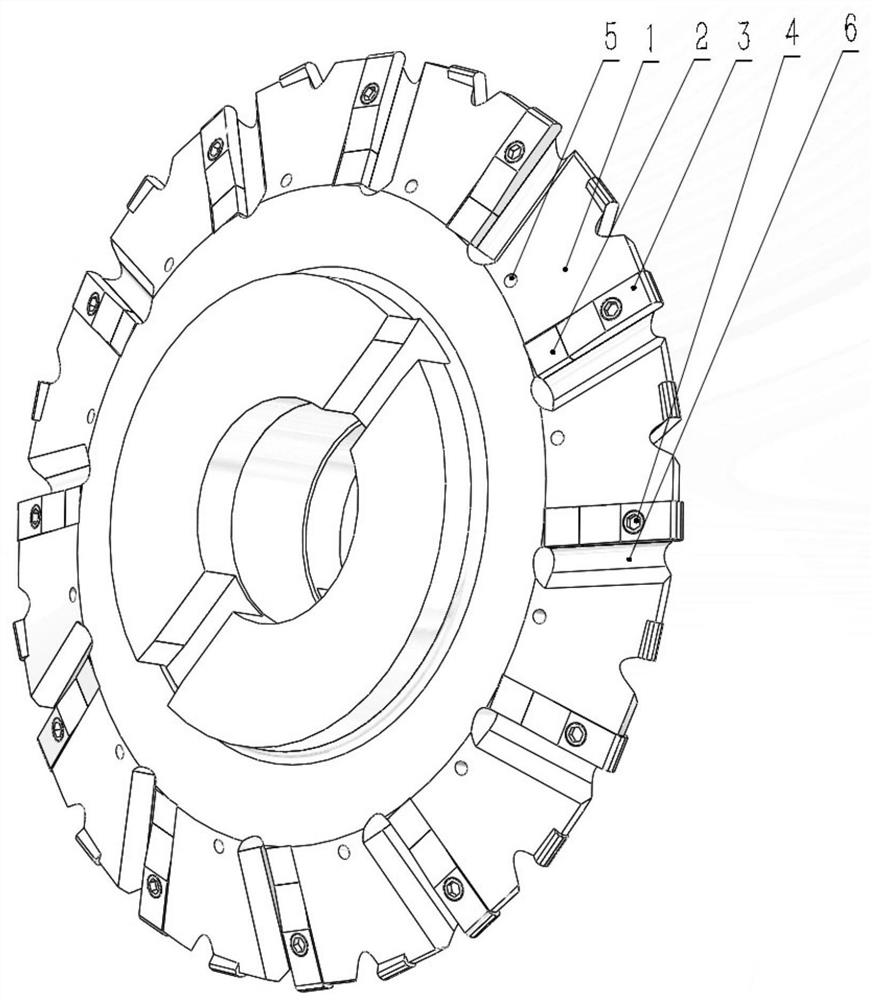

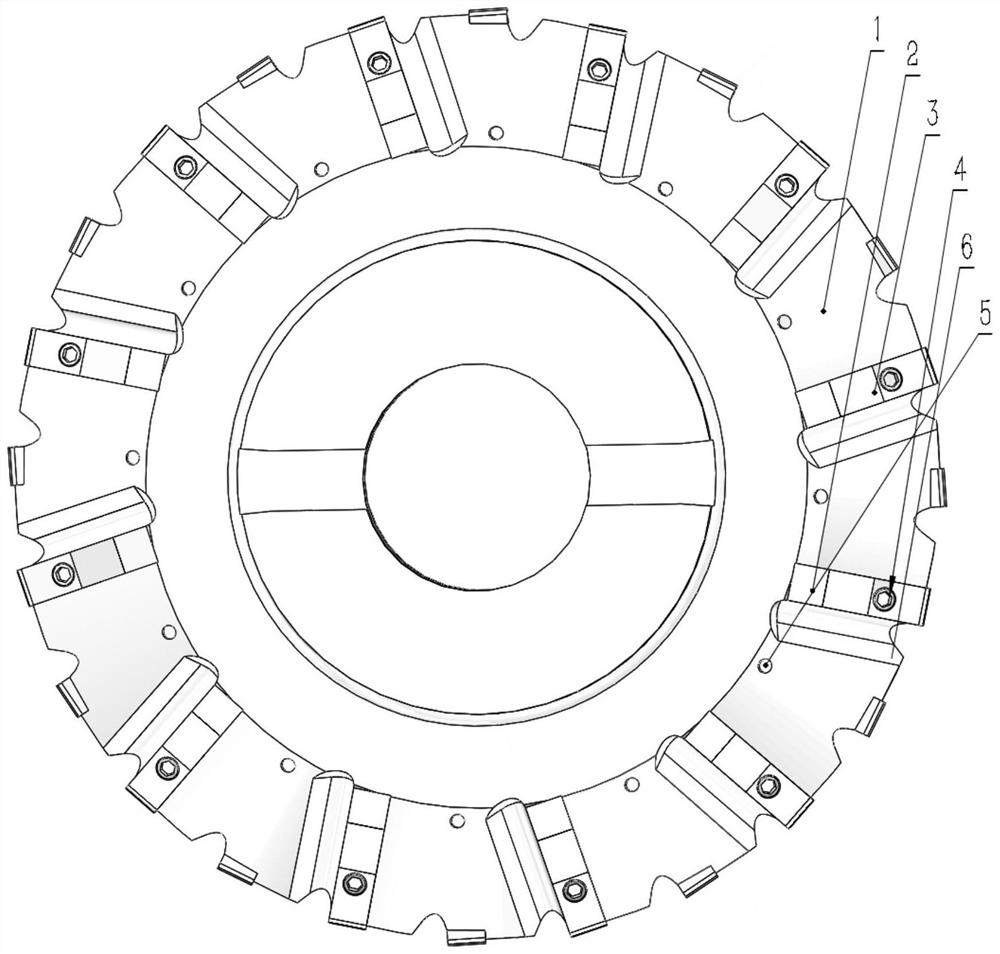

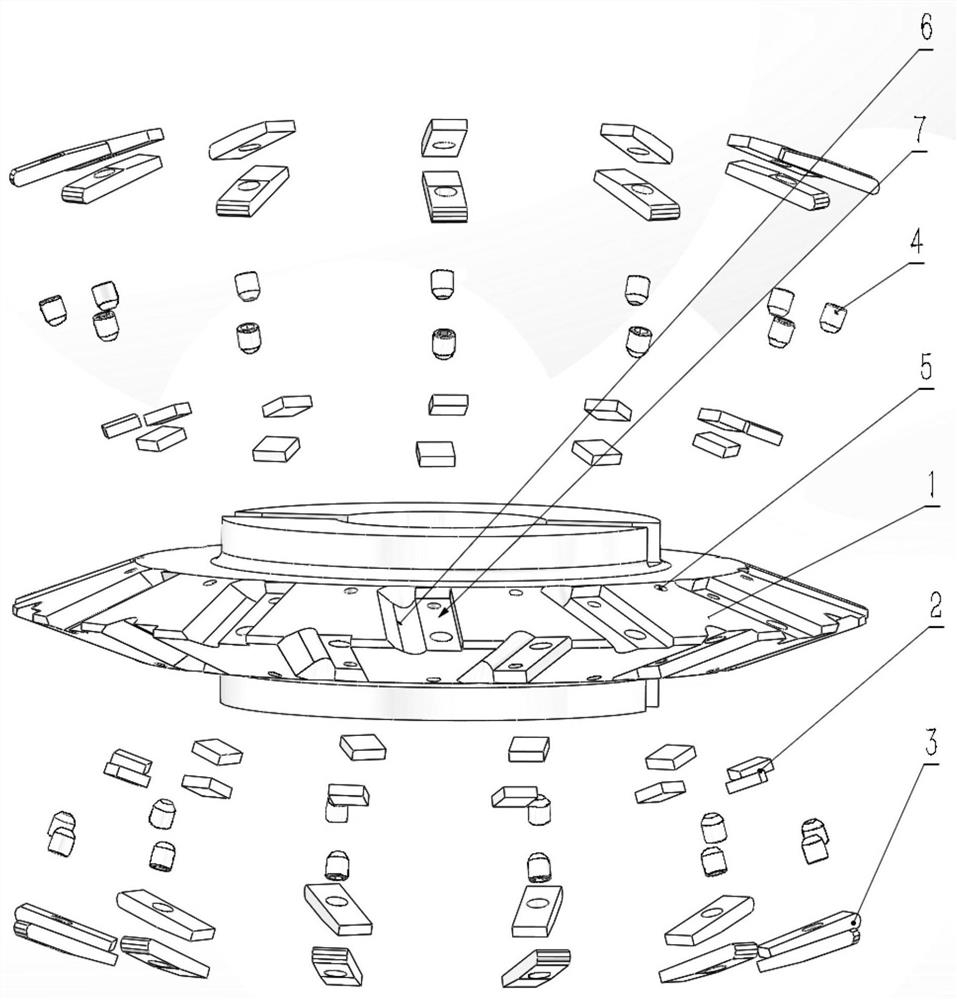

[0022] refer to Figure 1-Figure 6 , an indexable form milling cutter head device, the device does not separate the top edge milling blade 3 and the side edge milling blade 2 on the cutter head, but are placed together in a blade groove 7, A total of 24 sets of blade combinations are arranged on the cutter head base 1, 12 sets of blade combinations are evenly spaced on each side, and 12 sets of blade combinations are distributed on the other side with staggered teeth. At the same time, the chip flute 6 is designed next to the insert groove 7, and a section of smooth curved surface is lofted and cut off under the chip flute 6, so as to facilitate the rapid flow of chips.

[0023] In this embodiment, the top edge milling insert is designed according to the tooth profile curve in the principle of gear meshing. The top edge milling insert 3 is fastened on the cutterhead base 1 by the hexagon socket head screw 4, and the top edge milling insert 4 penetrates the top edge milling bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com