Leatherware production punching device with hole diameter adjusting structure

A punching device and aperture adjustment technology, which are used in leather punching/punching/cutting, raw hide/leather/fur manufacturing equipment, small raw hides/large raw hides/leather/fur processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

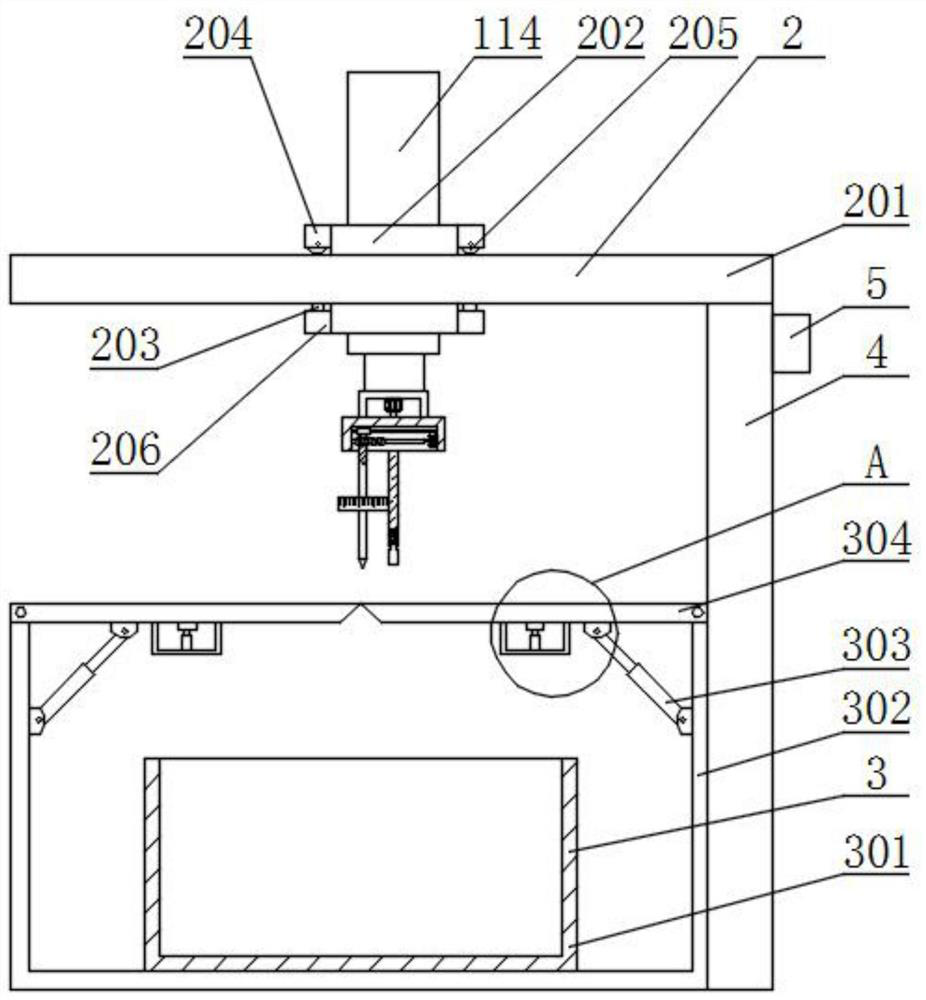

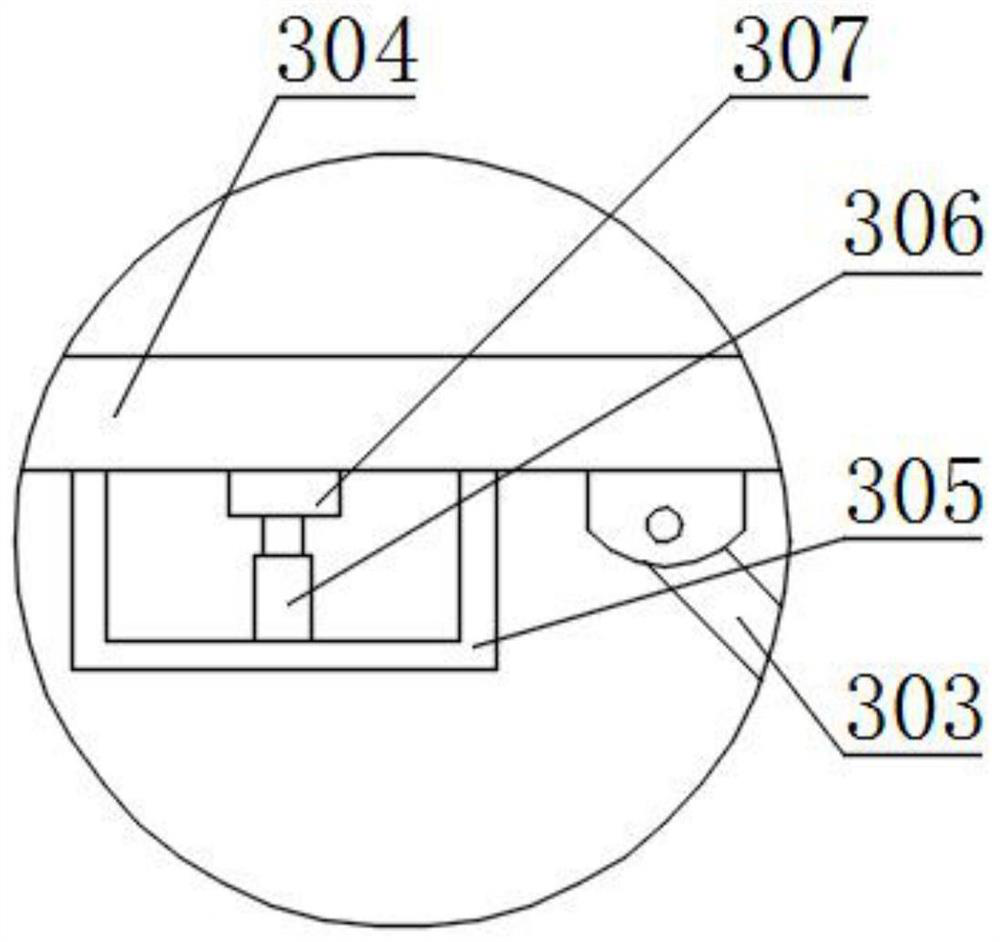

[0037] Such as Figure 1-2 As shown, a leather product production punching device with an aperture adjustment structure, one end of the side plate 4 is provided with a controller 5, the top of the side plate 4 is provided with an adjustment device 2, and one end of the adjustment device 2 is provided There is a punching device 1, the underside of the punching device 1 is provided with a collecting device 3, and the collecting device 3 and the side plate 4 are arranged, and the punching device 1 includes a first An electric telescopic rod 114, one side of the adjusting device 2 is provided with a first electric telescopic rod 114, and the bottom end of the first electric telescopic rod 114 is provided with a fixing bracket 101, and the fixing frame 101 can be realized by the first electric telescopic rod 114. Adjustment of the position of the frame 101, one side of the fixed frame 101 is provided with a first motor 102, the main shaft end of the first motor 102 is provided with...

Embodiment 2

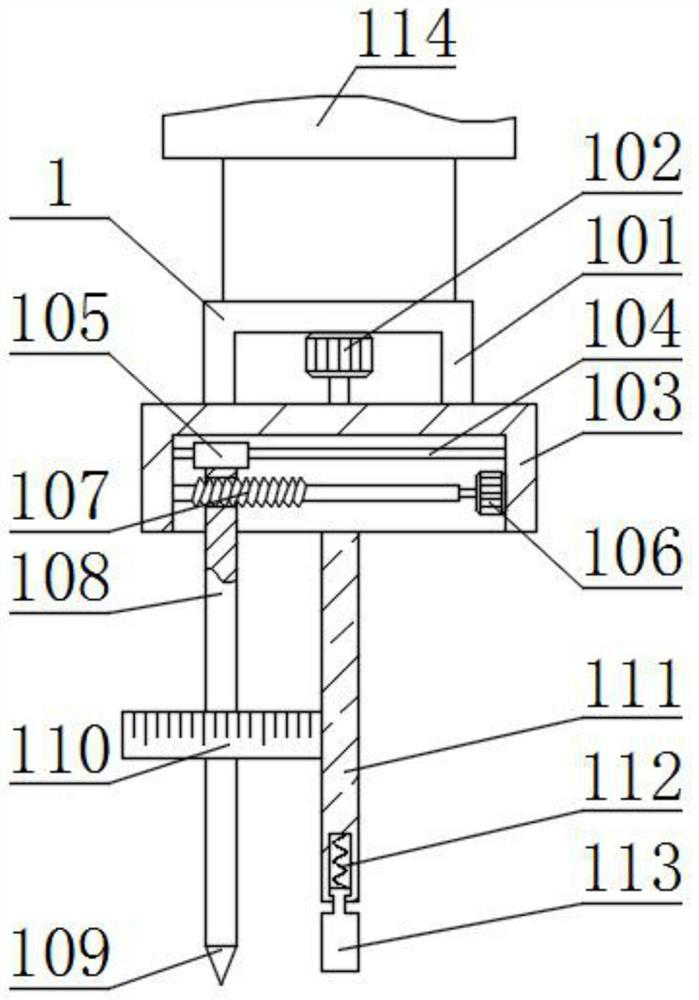

[0039] Such as figure 2 As shown, as a further optimization scheme of the above embodiment: a leather goods production punching device with an aperture adjustment structure, a controller 5 is provided at one end of the side plate 4, and an adjustment device 2 is provided at the top of the side plate 4 One end of the adjustment device 2 is provided with a punching device 1, the lower side of the punching device 1 is provided with a collecting device 3, and the collecting device 3 and the side plate 4 are provided, and the punching device 1 includes a The first electric telescopic rod 114 on one side of the adjustment device 2, the first electric telescopic rod 114 is provided on one side of the adjustment device 2, and the bottom end of the first electric telescopic rod 114 is provided with a fixing frame 101, through the first electric telescopic rod 114 An electric telescopic rod 114 can realize the adjustment to the position of the fixed frame 101, and one side of the fixed...

Embodiment 3

[0041] Such as figure 2 As shown, as a further optimization scheme of the above embodiment: a leather goods production punching device with an aperture adjustment structure, a controller 5 is provided at one end of the side plate 4, and an adjustment device 2 is provided at the top of the side plate 4 One end of the adjusting device 2 is provided with a punching device 1, the lower side of the punching device 1 is provided with a collecting device 3, and the collecting device 3 and the side plate 4 are provided, and one side of the fixing frame 101 is provided with The first motor 102, the main shaft end of the first motor 102 is provided with a connection frame 103, and the connection frame 103 is rotatably connected with the fixed frame 101, and one end side of the connection frame 103 is provided with a second motor 106, the first motor 106 The end of the main shaft of the second motor 106 is provided with an adjusting screw 107, the outer side of the adjusting screw 107 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com