Laminated slab module and pallet module and box body module of laminated slab

A technology of laminated boards and pallets, applied in bridge parts, bridge materials, building materials, etc., can solve problems such as easily affecting flexibility and convenience, poor impact resistance and moisture resistance of boards, and rising wood prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

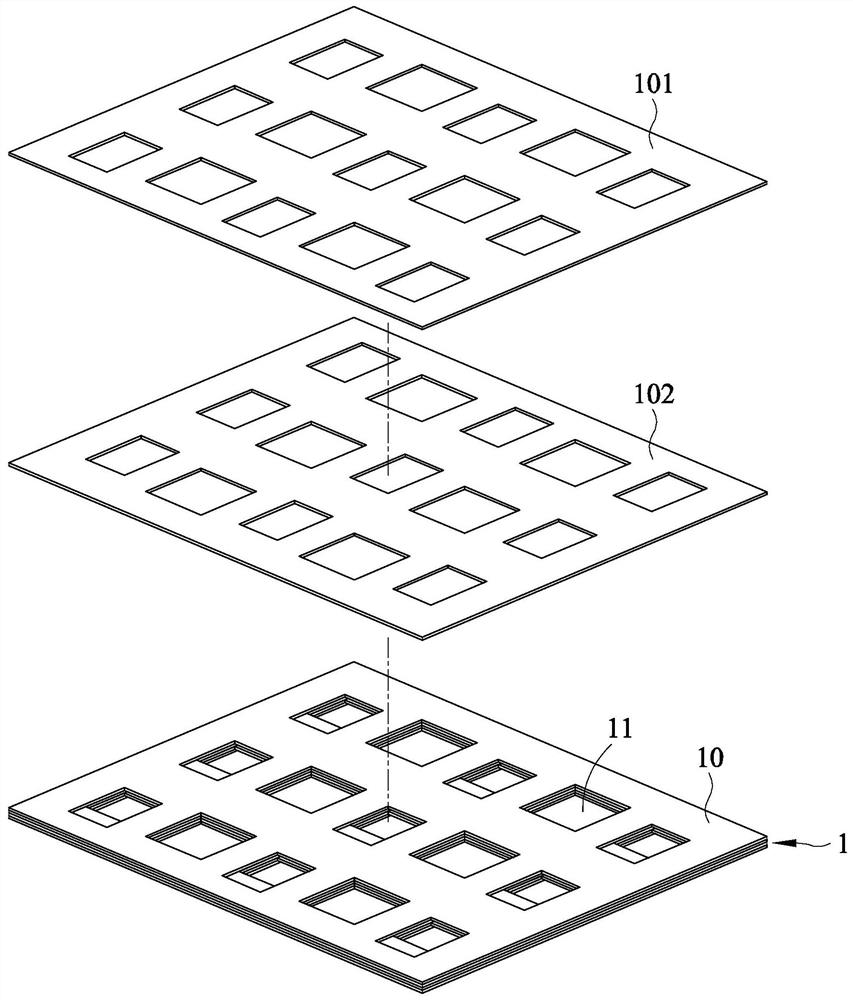

[0070] In the laminated board module disclosed by the present invention, the main board has greater rigidity due to the stacking of boards, and reduces weight and saves materials. Please refer to the following figure 1 , is an exploded schematic view of the first embodiment of the laminated board module of the present invention; in the figure, the main board 1 includes a plurality of boards 10 stacked, wherein at least one reduced structure is arranged on the board 10, and the reduced structures are identical and different The position and direction form the bearing surface, wherein the reduced structure is a plurality of perforations 11, and the perforations 11 can be rectangular or square. Differently, make the parts of the upper and lower perforations 11 communicate with each other, and set it to directly meet the needs of structural purposes, so as to save and reduce the processing procedures.

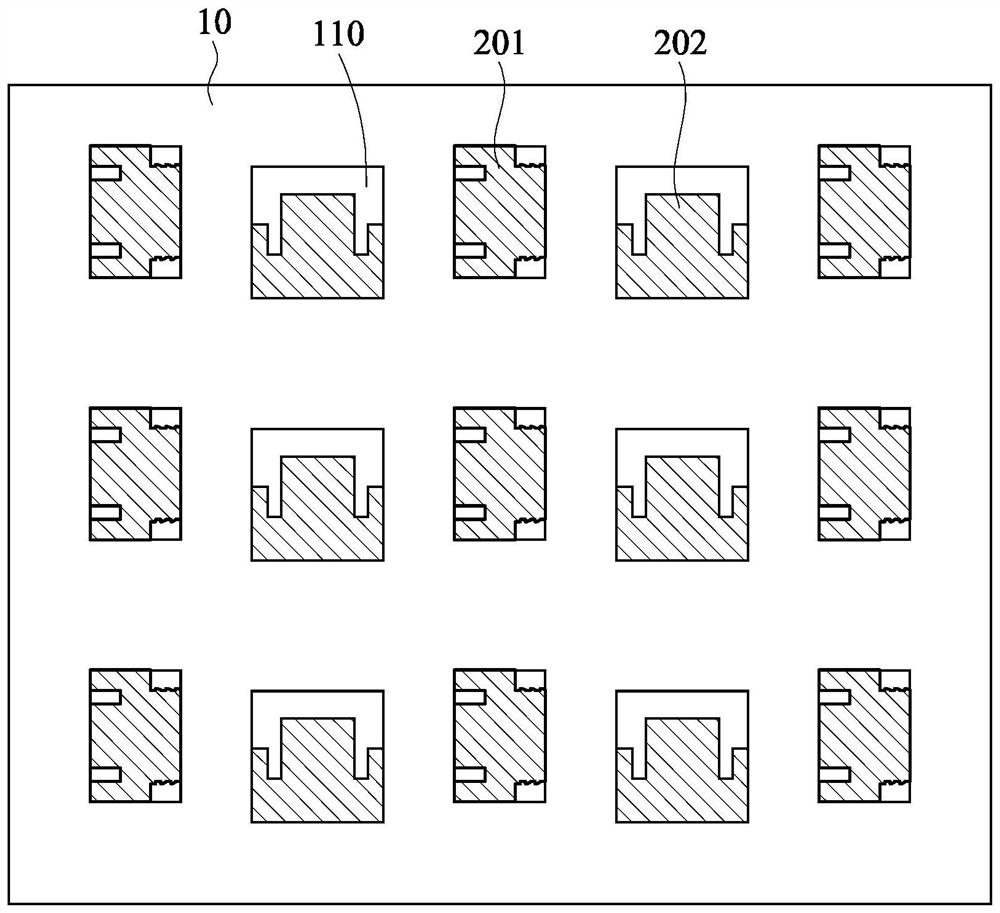

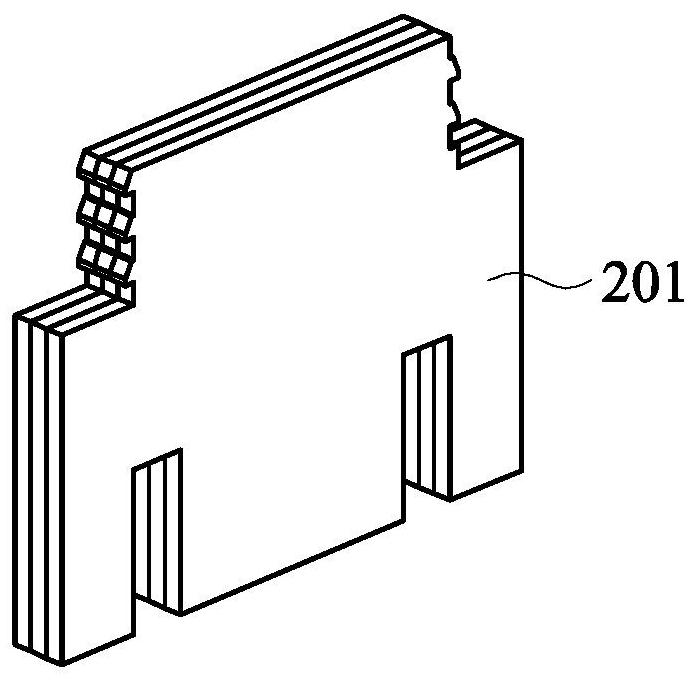

[0071] Next please refer to figure 2 , is a construction schematic diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com