Device for preheating boiler water through boiler chimney smoke

A technology for preheating boilers and chimneys, applied in the field of boiler chimney flue gas preheating boiler water devices, can solve the problems of low-temperature water and high-temperature hot gas heat exchange efficiency reduction, heat transfer effect reduction, aggravated air pollution, etc., to improve utilization , to ensure cleanliness and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

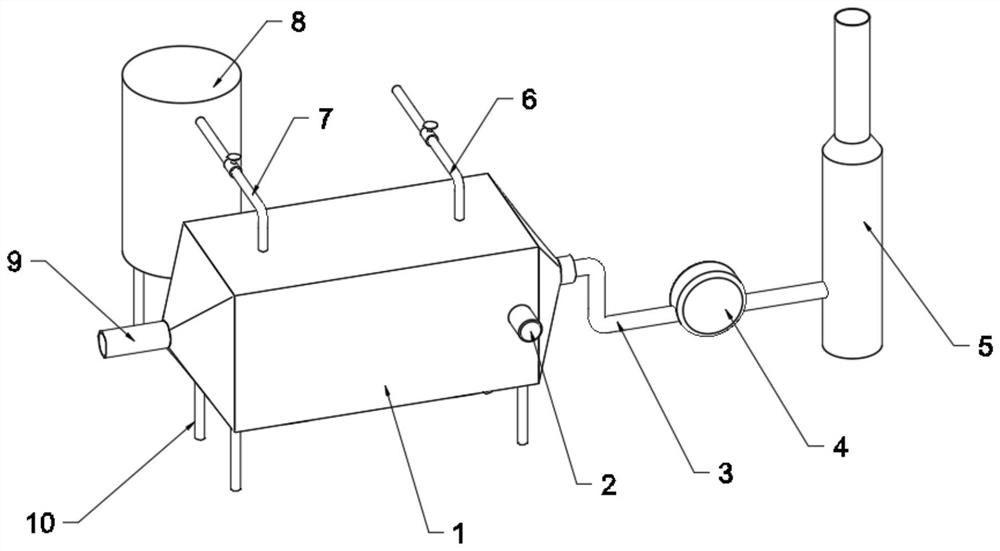

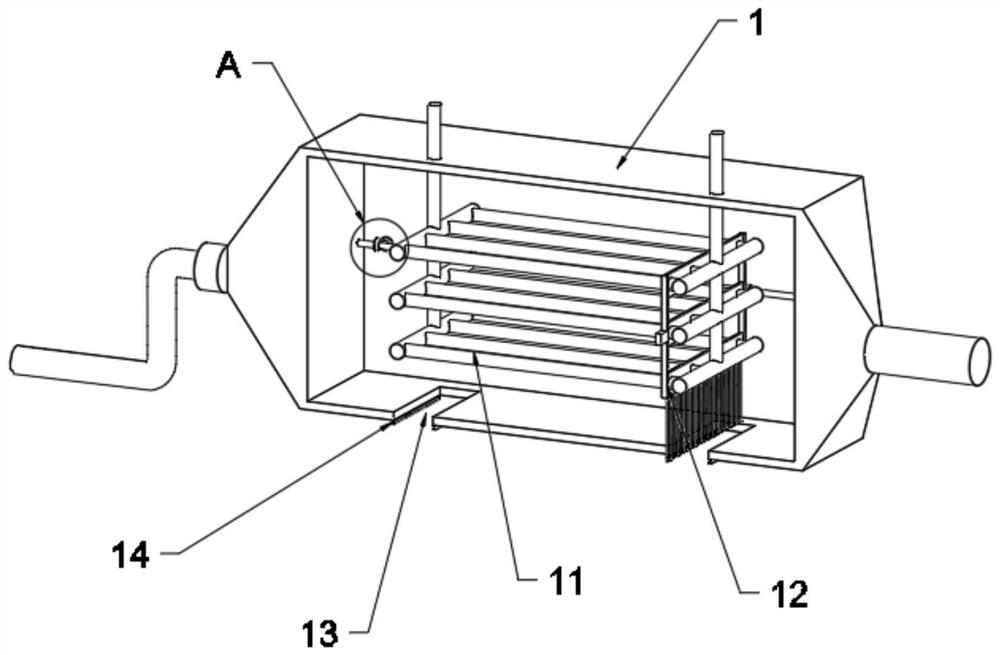

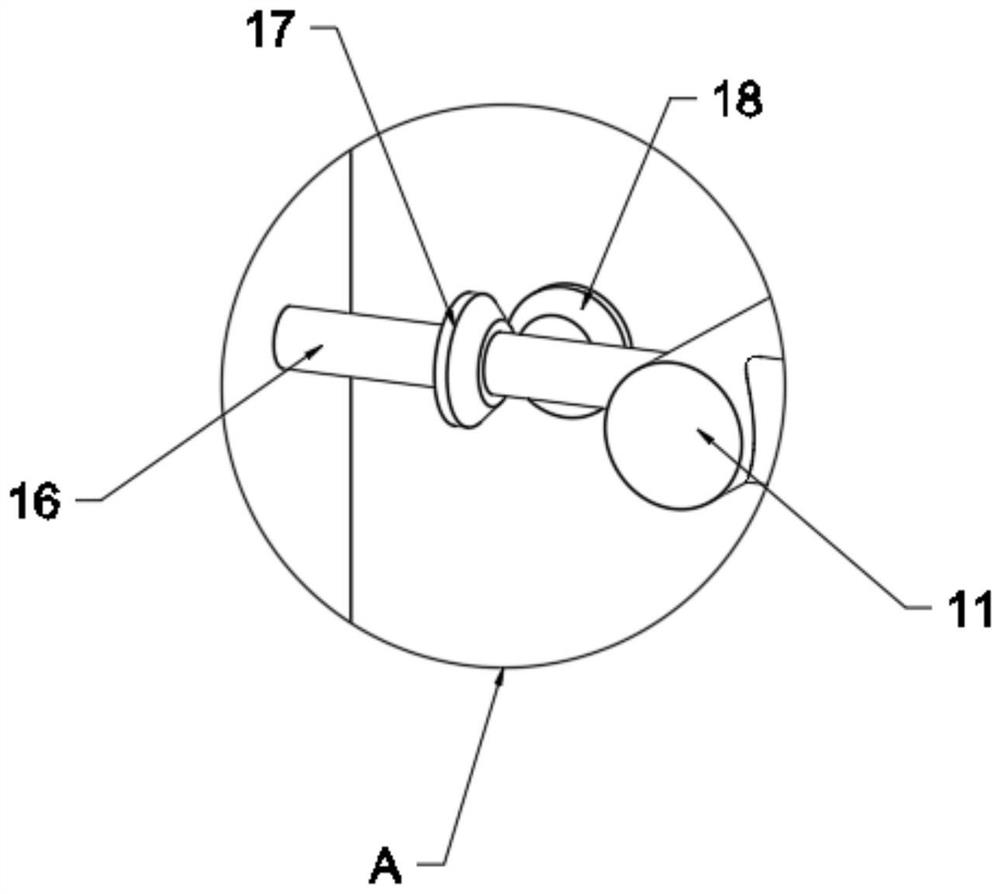

[0037] see Figure 1-5 , a boiler chimney flue gas preheating boiler water device, comprising a heat exchange box 1, a hot water storage tank 8 and a heat exchange tube 11; one end of the heat exchange box 1 is connected to the boiler through a smoke inlet pipe 9, and the heat exchange box 1 The other end is connected with the chimney 5 through the smoke outlet pipe 3, and the hot gas burned by the boiler flows into the heat exchange box 1 from the smoke inlet pipe 9, and then flows into the chimney 5 from the smoke outlet pipe 3 to be discharged; It is beneficial to discharge the hot gas in the boiler from the chimney 5 .

[0038] Both the heat exchange box 1 and the hot water storage tank 8 are installed on the ground through support feet 10 .

[0039] The upper end surface of the heat exchange box 1 is respectively provided with a water inlet pipe 6 and an outlet pipe 7, the water inlet pipe 6 is connected with the tap water pipe, and the outlet pipe 7 is connected with th...

Embodiment 2

[0045] see Figure 6 , the present embodiment adds the following scheme on the basis of Embodiment 1, the two ends of the bottom surface of the heat exchange box 1 are symmetrically provided with fouling notches 13, and the lower end of the descaling and fouling is provided with sweeping scales into the fouling notch The bristle 124 of 13, the outside of fouling notch 13 is provided with collecting mechanism.

[0046] The collection mechanism includes a fixed frame 14 arranged on both sides of the fouling notch 13 and a fouling box 15 arranged on the fixed frame 14. The upper end of the fixed frame 14 is fixedly connected to the lower end surface of the heat exchange box 1, and the two fixed frames 14 A second chute 141 is provided on the opposite surface of the dirt box 15 , and a second sliding protrusion 152 is provided on both sides of the upper end of the fouling box 15 , and the second sliding protrusion 152 is slidably connected in the second chute 141 .

[0047] The u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap