Method for monitoring SF6 density relay in real time and pre-judging gas leakage

A density relay and real-time monitoring technology, which is applied in the direction of measuring the increase and deceleration rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, instruments, etc., can solve the problem that the air leakage cannot be predicted, and the gas density relay cannot be monitored in real time, etc. problems, to achieve the effects of convenient monitoring and early warning, accurate compensation, and guaranteed accuracy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for real-time monitoring and pre-judging air leakage of SF6 density relays, comprising the following steps:

[0043] S1: Pressure and temperature integrated sensor 4 pairs of SF 6 SF inside a density relay 6 Gas real-time detection pressure value; SF 6 Density relays are used to monitor SF in closed containers 6 The density value of the gas, in order to facilitate the unification of inflation and monitoring standards, the industry often uses P 20 The value is the pressure value at 20°C to characterize; the pressure and temperature integrated sensor 4 real-time SF 6 The gas in the density relay is detected, and its specific model can be TE's 89BSD-012BA-8. The sensor has high measurement accuracy, small compensation error, accuracy ±0.3%, and wide operating temperature range -40 ° C ~ +85 ° C; preferred In this implementation, the pressure and temperature integrated sensor 4 is directly connected to the SF 6 SF inside a density relay 6 Gas contact and dete...

Embodiment 2

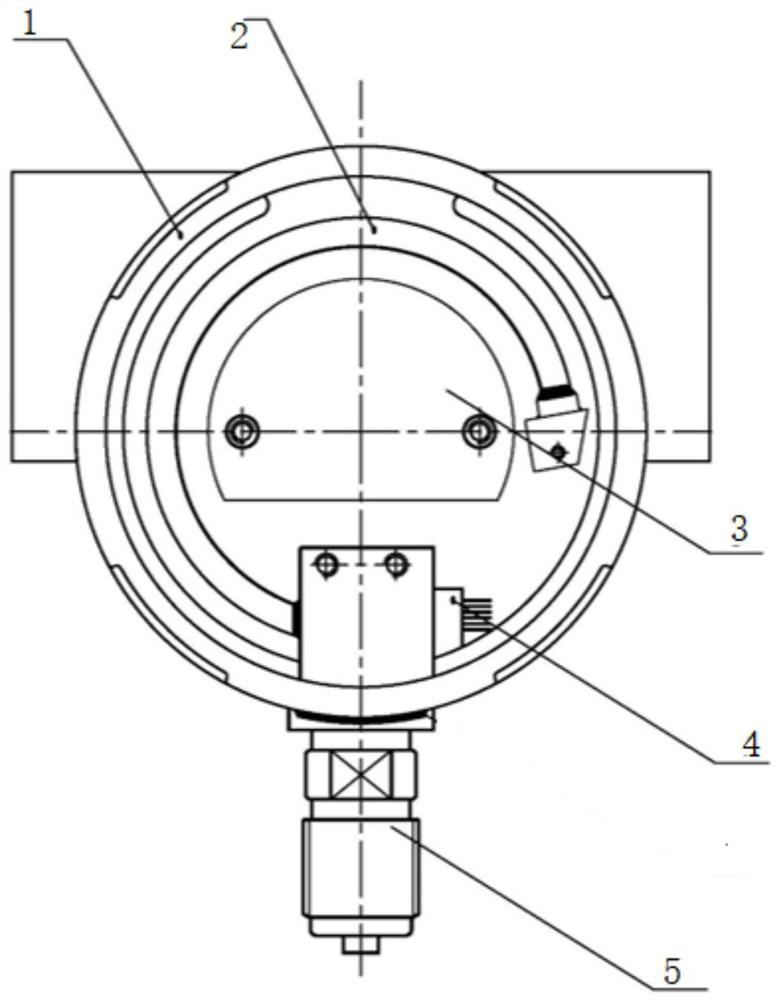

[0056] Basically the same as embodiment 1, such as figure 1 As shown, in this implementation SF 6 The density relay includes a housing 1, which plays the role of overall sealing and support; the housing 1 is connected to the external pressure vessel through the joint 5, and the external pressure vessel is loaded with SF 6 gas container, the SF inside the container 6 The gas enters the housing 1 through the connection 5 . The housing 1 is provided with a spring tube 2 and a transmitter 3. One end of the spring tube 2 is connected to the joint 5. The spring tube 2 is a pressure-sensitive element. Because the spring tube 2 is hollow inside, SF 6 The gas enters the spring tube 2 directly through the connection 5, SF 6 The gas rushes into the spring tube 2 to elastically deform it. The spring tube 2 is equipped with a pressure and temperature integrated sensor 4, which is electrically connected to the transmitter 3, and the transmitter 3 is embedded with a chip to calculate the...

Embodiment 3

[0060] Basically the same as embodiment 2, in order to further improve the overall work efficiency, the steps S3 and S4 can be replaced by the following steps:

[0061] S5: put T 1 ~T 2 Several equivalent pressure values within the time period are compared with the threshold value one by one, if the threshold value is exceeded, it will be recorded once, and when the recording times exceed the preset value, the SF will be judged 6 Density relay leaks, the threshold value is -0.035Mpa, the preset value here can be set according to the specific situation, while ensuring T 1 ~T 2 The time period goes through three stages of temperature rise, constant temperature and temperature drop to ensure the comprehensiveness of data collection, avoid large errors in short-term measurement, and improve the accuracy of the entire judgment process; by recording the number of times exceeding the threshold and setting the value Compare and judge SF 6 The density relay leaks air, the judgmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com