Anesthesia cabin with waste gas recovery effect for anesthesia room

A waste gas recovery, anesthesia room technology, applied in veterinary instruments, medical science, dispersed particle separation, etc., can solve the problem of long time required for anesthesia, and achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

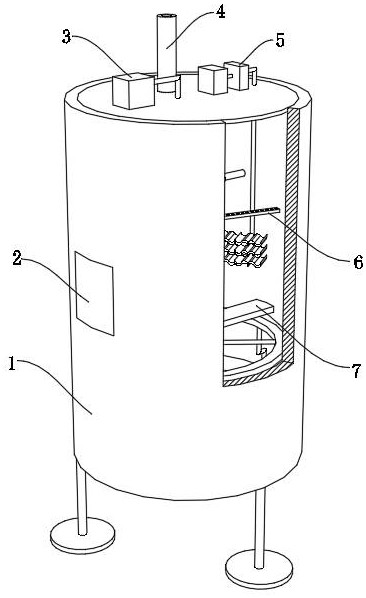

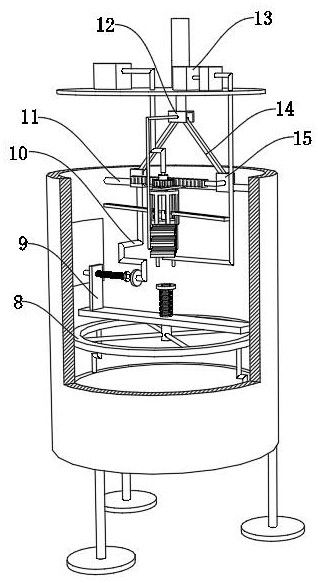

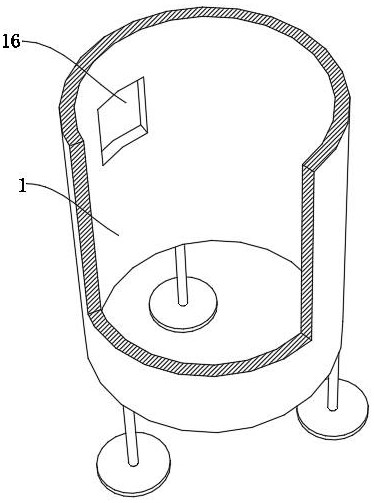

[0035] An anesthesia cabin for an anesthesia room with waste gas recovery effect, such as Figure 1-6As shown, it includes an anesthesia cabin main body 1, the inner wall of the arc surface of the anesthesia cabin main body 1 is fixed with a traverse column 11 by bolts, and the outer wall of the traverse column 11 is slidably connected with two sliding seats 15, and the anesthesia cabin main body 1 The outer wall of the top is fixed with an electric telescopic rod 4 by bolts, and the output end of the electric telescopic rod 4 is fixed with a lifting frame 12 by bolts, and the inner wall of the lifting frame 12 is rotatably connected with two connecting rods 14, and the two connecting rods 14 are away from One end of the lifting frame 12 is respectively rotatably connected to the inner walls of two sliding seats 15, wherein the outer wall of one side of the sliding seat 15 is fixed with a rack 21 by bolts, and the outer wall of the traverse column 11 is fixed with a guard plate...

Embodiment 2

[0041] An anesthesia cabin for an anesthesia room with waste gas recovery effect, such as Figure 1-5 As shown, in order to collect the exhaust gas produced in the anesthesia process; this embodiment makes the following supplements on the basis of embodiment 1: the outer wall of the top of the anesthesia cabin main body 1 is fixed with an adsorption stuffing box 5 and an exhaust fan 13 by bolts, and the The adsorption stuffing box 5 and the exhaust fan 13 are plugged and fixed through a hose, and one end of the adsorption stuffing box 5 is plugged into the bottom end of the guide hollow column 28 through a hose, and the exhaust fan 13 can be used to control the main body of the anesthesia cabin. 1, the anesthesia waste gas inside is sucked, and the sucked anesthesia waste gas can enter the interior of the adsorption stuffing box 5 through a hose for adsorption, so as to avoid air pollution caused by the residual anesthesia waste gas; the outer wall of the top of the guide hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com