Vibration fastening and clamping device for electronic component production

A technology for electronic components and fastening clips is applied in the field of vibration fastening and clamping devices for electronic component production, which can solve the problem that the clamping equipment cannot be automatically vibrated and fastened, and achieves reducing vibration, increasing clamping force, Increase the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

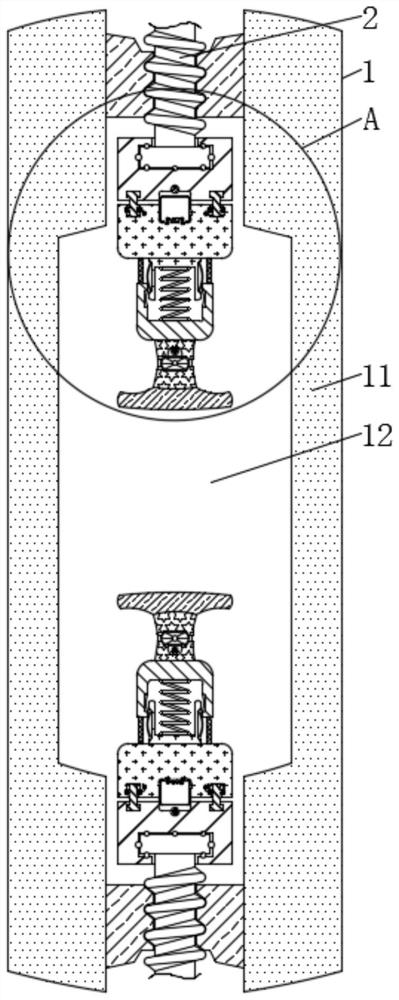

[0027] see Figure 1-2 , a vibration fastening and clamping device for the production of electronic components, comprising a housing 1, the housing 1 includes a housing 11, a working chamber 12, the housing 11 is provided with a working chamber 12, the housing 1 is made of metal material, and the housing 1 includes a structure Body and power supply system, through the mutual cooperation between the shell 1 and the propulsion mechanism 2, when the propulsion mechanism 2 rotates, it will drive the cooperation mechanism 3 to move, realize the automatic clamping function of the product, prevent the clamping from loosening, and ensure the clamping Stable performance, the top and bottom of the shell 1 are movably connected with the propulsion mechanism 2, the inner side of the propulsion mechanism 2 is movably connected with the cooperating mechanism 3, the inner side of the coordinating mechanism 3 is movably connected with the booster mechanism 4, and the inner side of the booster ...

Embodiment 2

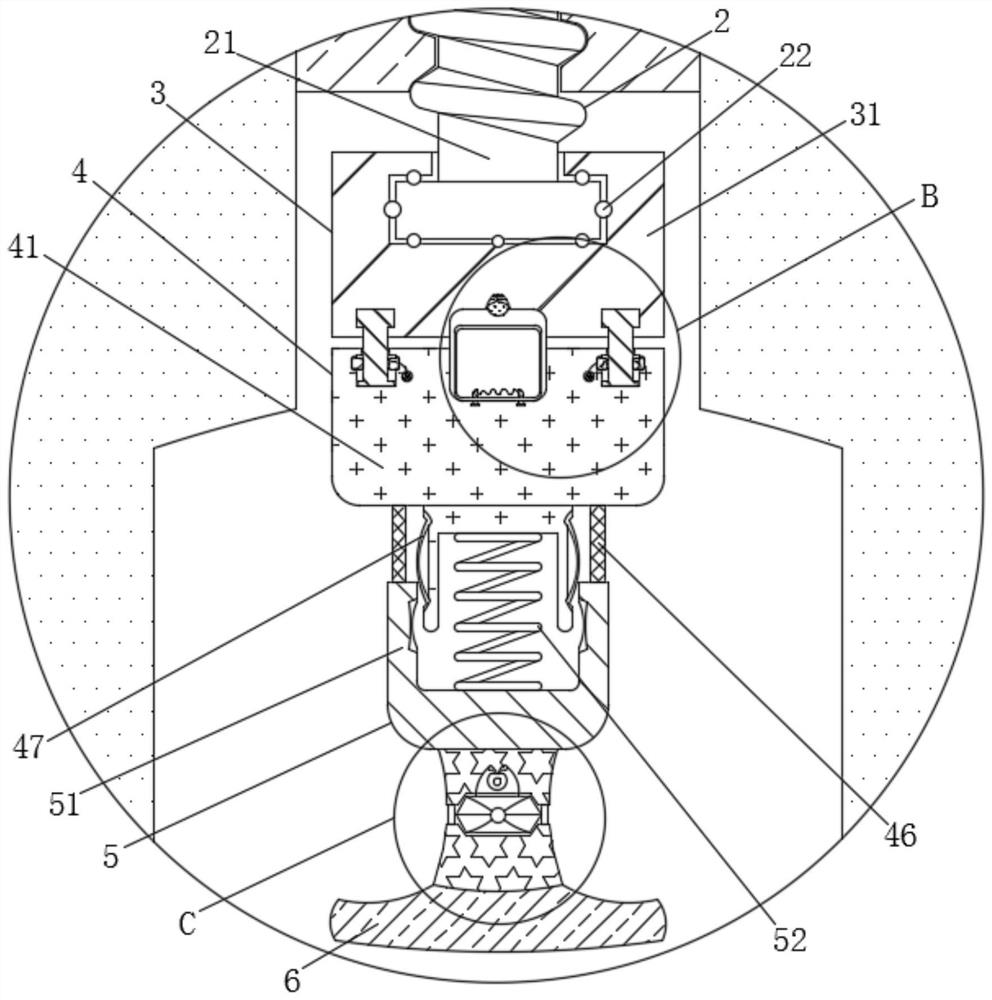

[0029] see Figure 1-3 , a vibration fastening and clamping device for the production of electronic components, comprising a housing 1, the housing 1 includes a housing 11, a working chamber 12, the housing 11 is provided with a working chamber 12, the housing 1 is made of metal material, and the housing 1 includes a structure Body and power supply system, through the mutual cooperation between the shell 1 and the propulsion mechanism 2, when the propulsion mechanism 2 rotates, it will drive the cooperation mechanism 3 to move, realize the automatic clamping function of the product, prevent the clamping from loosening, and ensure the clamping Stable performance, the top and bottom of the shell 1 are movably connected with the propulsion mechanism 2, the propulsion mechanism 2 includes the screw-in rod 21, the ball 22 and the control motor, the top and the top of the shell 1 are movably connected with the screw-in rod 21, the inside of the screw-in rod 21 Evenly distributed bal...

Embodiment 3

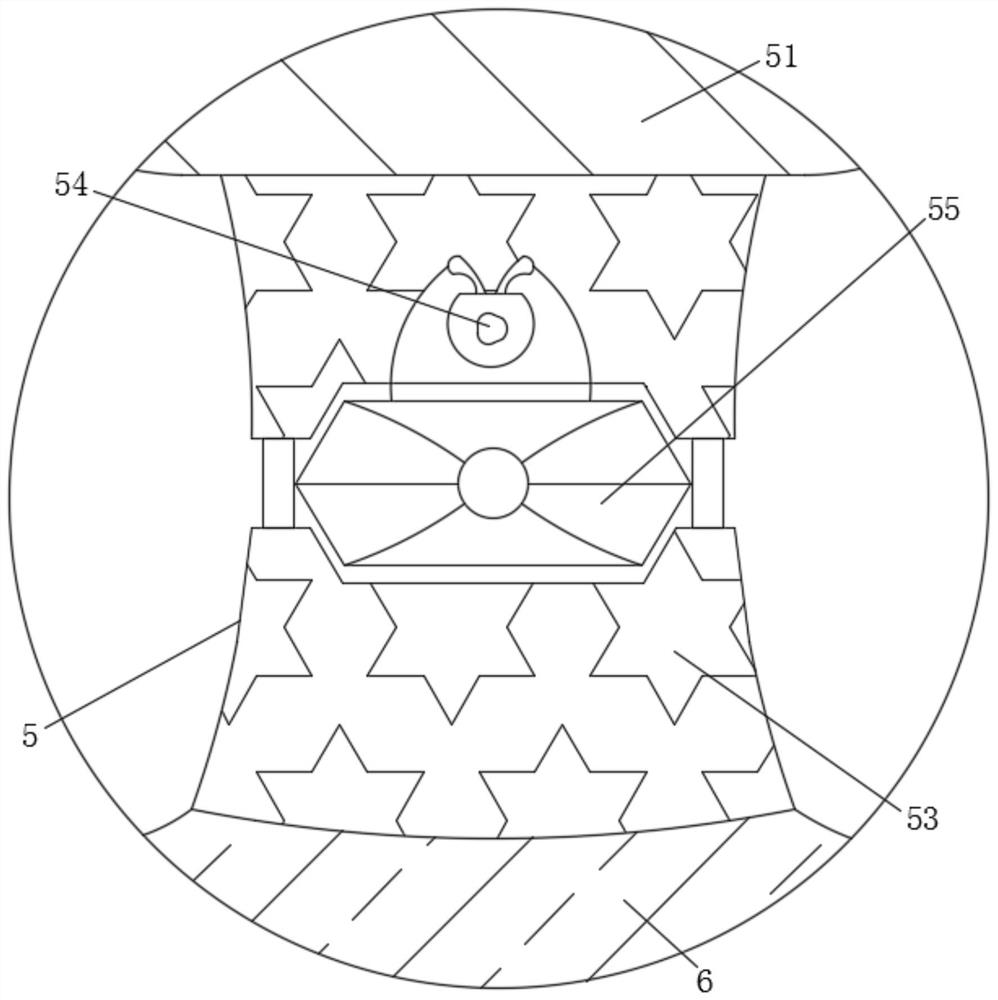

[0032] see Figure 1-4 , a vibration fastening and clamping device for the production of electronic components, comprising a housing 1, the housing 1 includes a housing 11, a working chamber 12, the housing 11 is provided with a working chamber 12, the housing 1 is made of metal material, and the housing 1 includes a structure Body and power supply system, through the mutual cooperation between the shell 1 and the propulsion mechanism 2, when the propulsion mechanism 2 rotates, it will drive the cooperation mechanism 3 to move, realize the automatic clamping function of the product, prevent the clamping from loosening, and ensure the clamping Stable performance, the top and bottom of the shell 1 are movably connected with the propulsion mechanism 2, the propulsion mechanism 2 includes the screw-in rod 21, the ball 22 and the control motor, the top and the top of the shell 1 are movably connected with the screw-in rod 21, the inside of the screw-in rod 21 Evenly distributed bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com