Table type dust collection saw

A technology for dust collection saws and table saws, used in circular saws, sawing equipment, bark area/debris/dust/waste removal, etc., can solve the problems of increased weight, increased motor cost, increased use and operation, etc. The effect of reducing the number of motors, reducing the energy burden, and cost is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

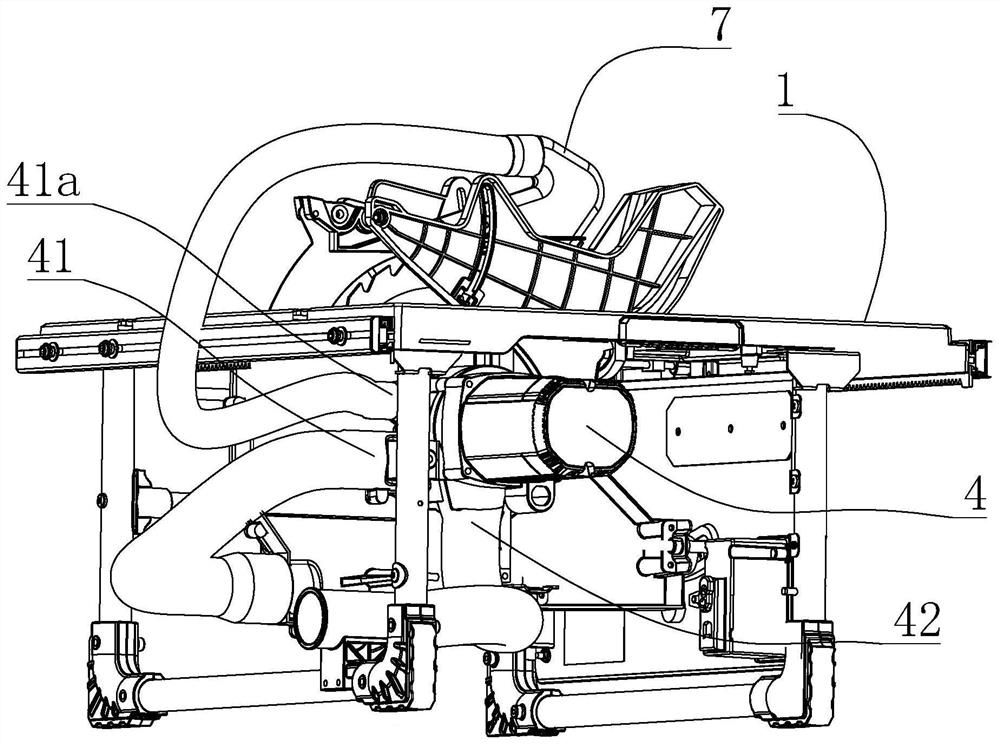

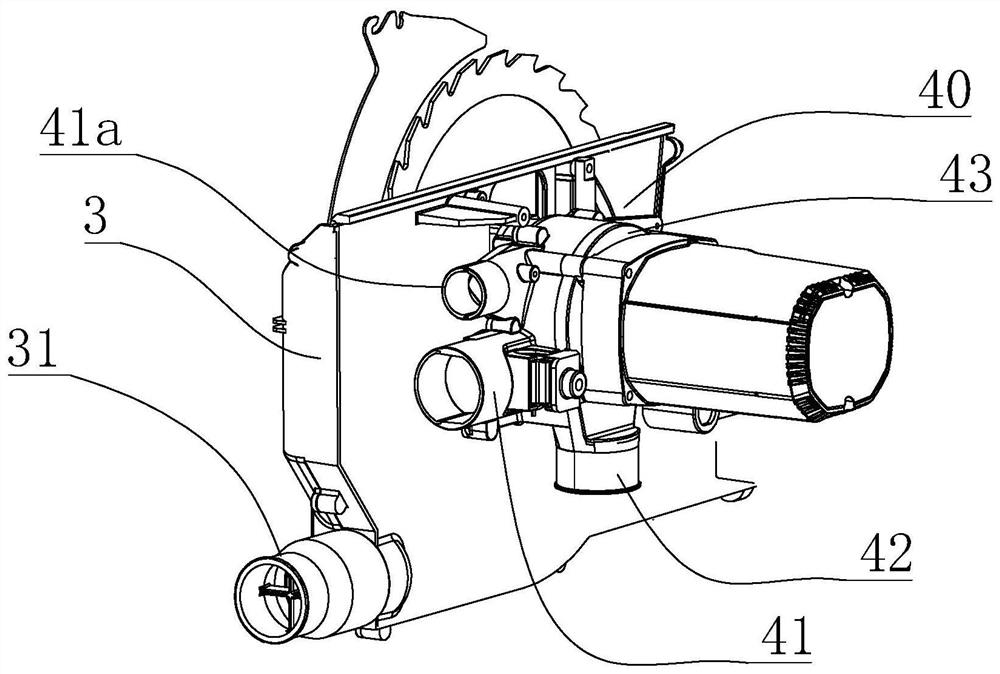

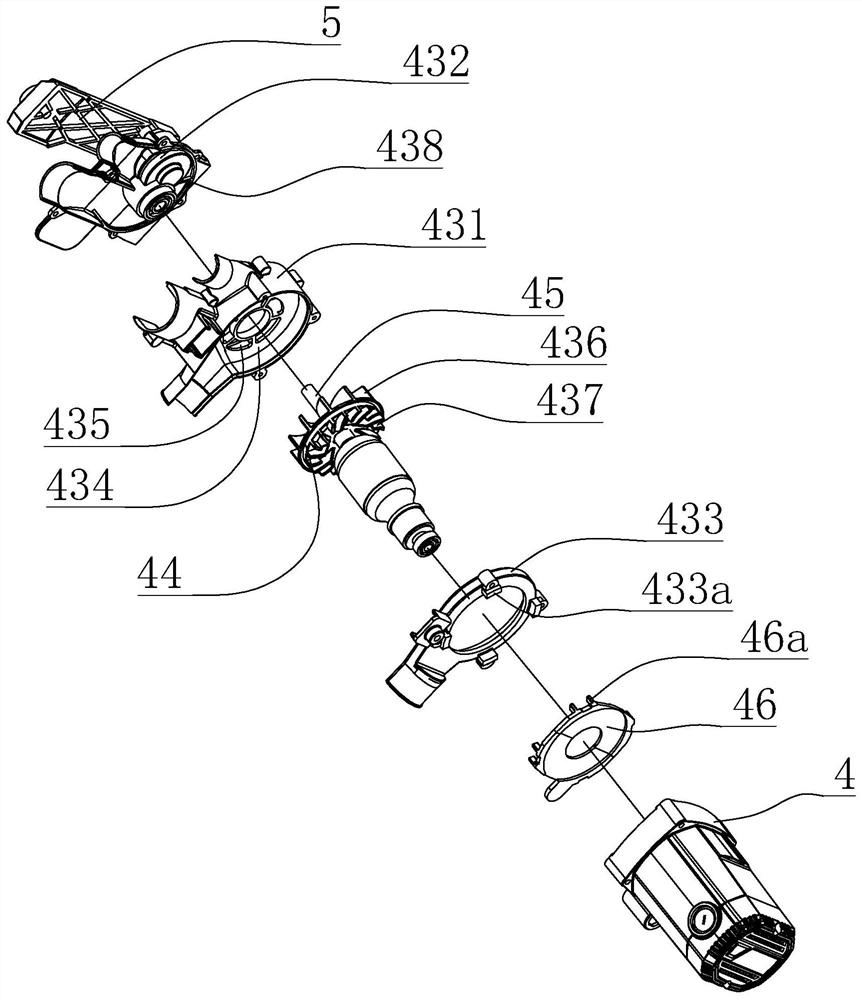

[0030] Such as figure 1 As shown, a desktop dust-collecting saw includes a workbench 1, a table saw 2 installed on the workbench 1, and a lower dust cover 3 that surrounds the saw blade below the workbench 1 and is arranged on the workbench 1. The upper dust cover 7 surrounding the saw blade above the table saw 2 above the table 1;

[0031] The lower dust cover 3 is provided with a dust outlet 31 , and the side near the upper end of the lower dust cover 3 away from the motor 4 is provided with a retractable flexible shielding curtain 6 . The purpose of setting up the flexible screen is that when the table saw 2 adjusts the angle of the saw blade for miter cutting, there will be a certain gap between the table saw 2 and the workbench 1 after the vertical state is changed to a certain angle. The retractable function of the flexible shielding curtain is used to compensate, so that the lower dust cover 3 can still form a complete airtight state with the workbench 1 even if the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com