Loading safety device for high-rail semitrailer

A safety device and semi-trailer technology, which is applied in vehicle safety arrangement, pedestrian/passenger safety arrangement, belt fixing device, etc., can solve problems such as poor safety guarantee of staff, and achieve the effect of expanding the working radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

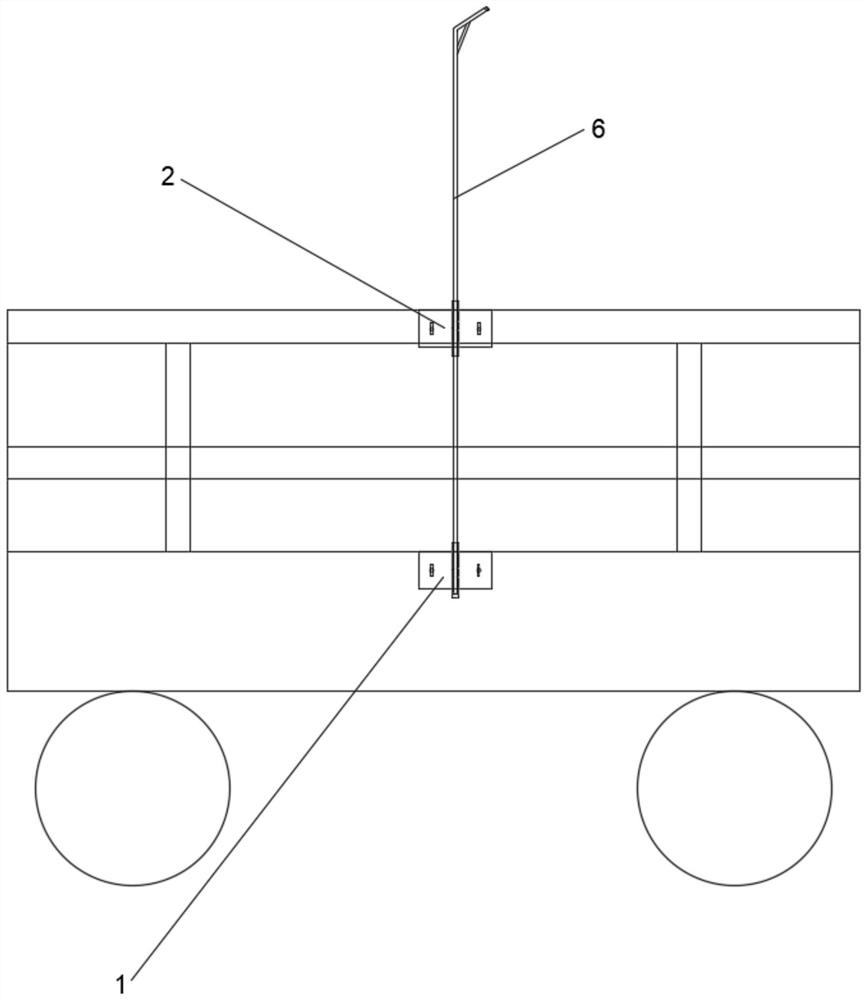

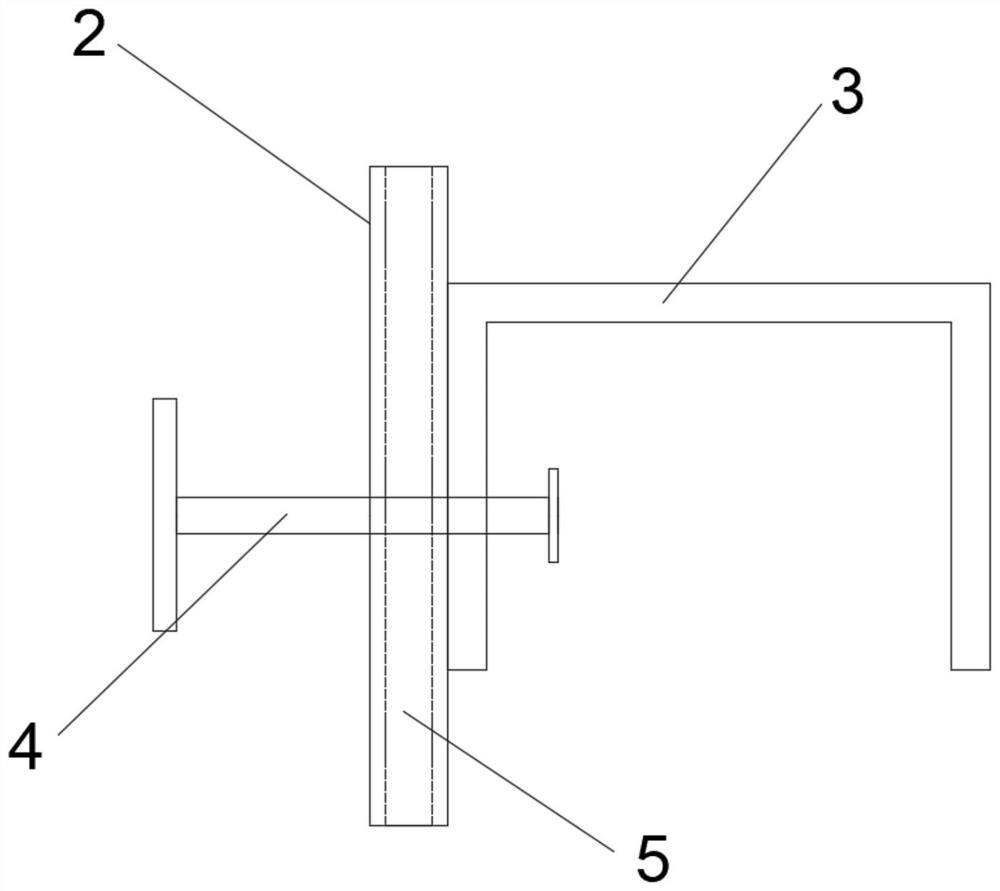

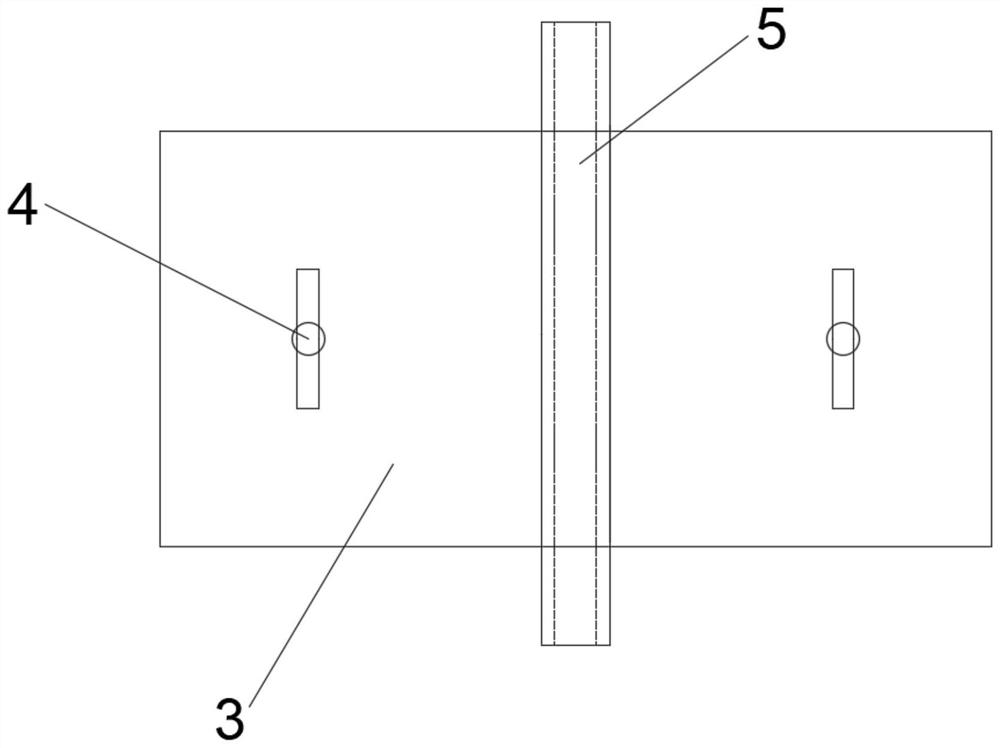

[0021] Such as Figure 1-6 As shown, a safety device for loading a high-rail semi-trailer according to the present invention includes a lower locking device 1 and an upper locking device 2, and the lower locking device 1 and the upper locking device 2 are all connected by a U-shaped card. Groove 3, jacking bolt 4 and intubation tube 5 are composed, one side of the U-shaped card slot 3 is fixedly connected with intubation tube 5, U-shaped card slot 3 is provided with jacking bolt 4, and the lower locking device 1 A seat belt hanging rod 6 is plugged into the inside of the insertion tube 5 of the upper locking device 2, and the number of jacking bolts 4 on the lower locking device 1 and the upper locking device 2 is two, and the two jacking bolts 4 are two. The tightening bolts 4 are distributed on the left and right sides of the intubation tube 5, the lower locking device 1 is fixedly connected to the lower compartment through the tightening bolts 4, and the upper locking devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com