Lifting mechanism for tropical fruit processing

A tropical fruit and lifting rack technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as damage to the transmission mechanism, product misplaced falling, product dumping damage, etc., to increase stability and avoid tilting. drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

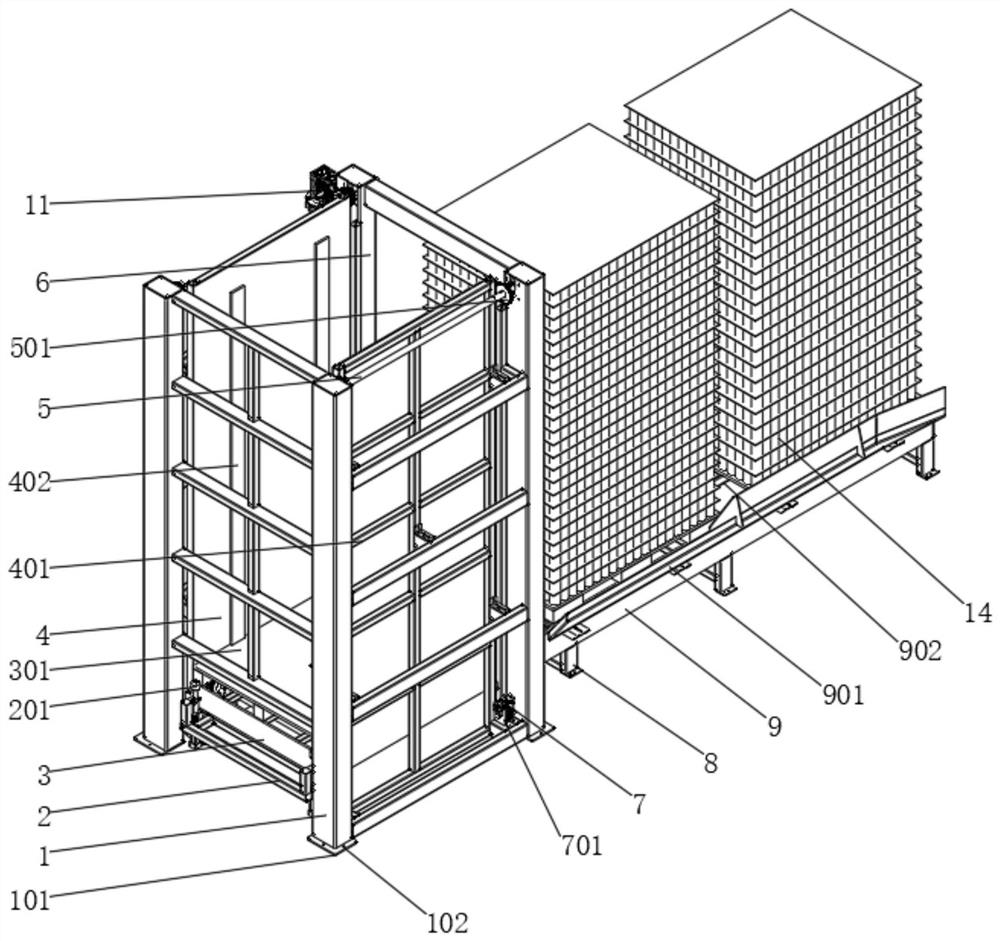

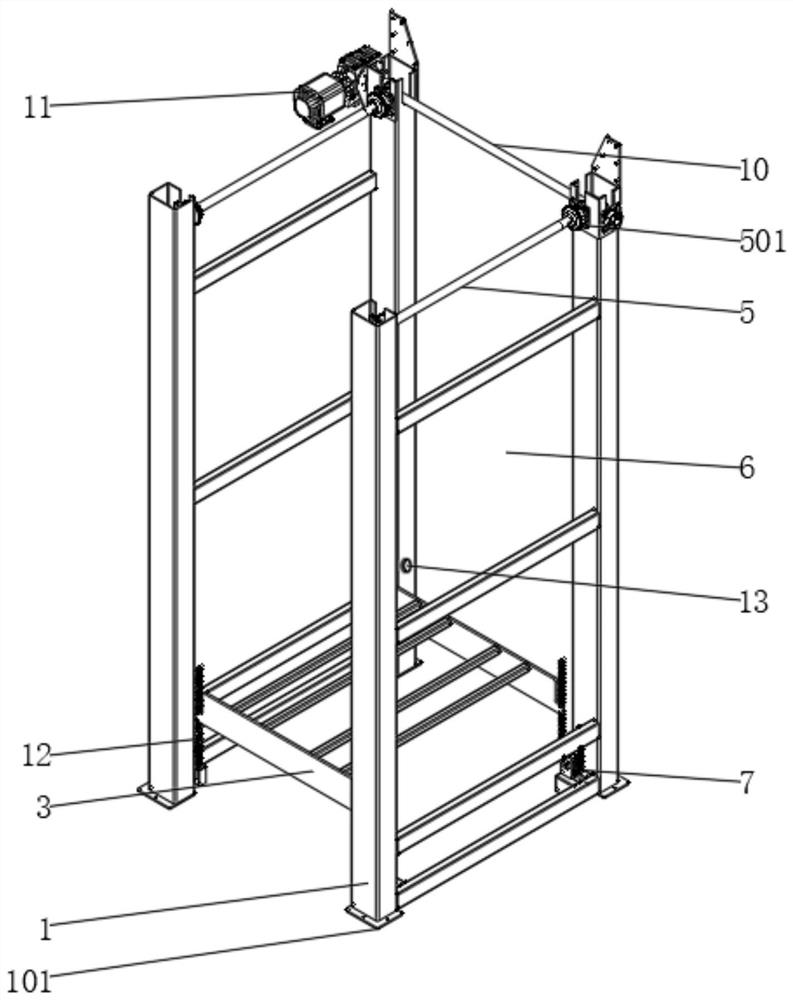

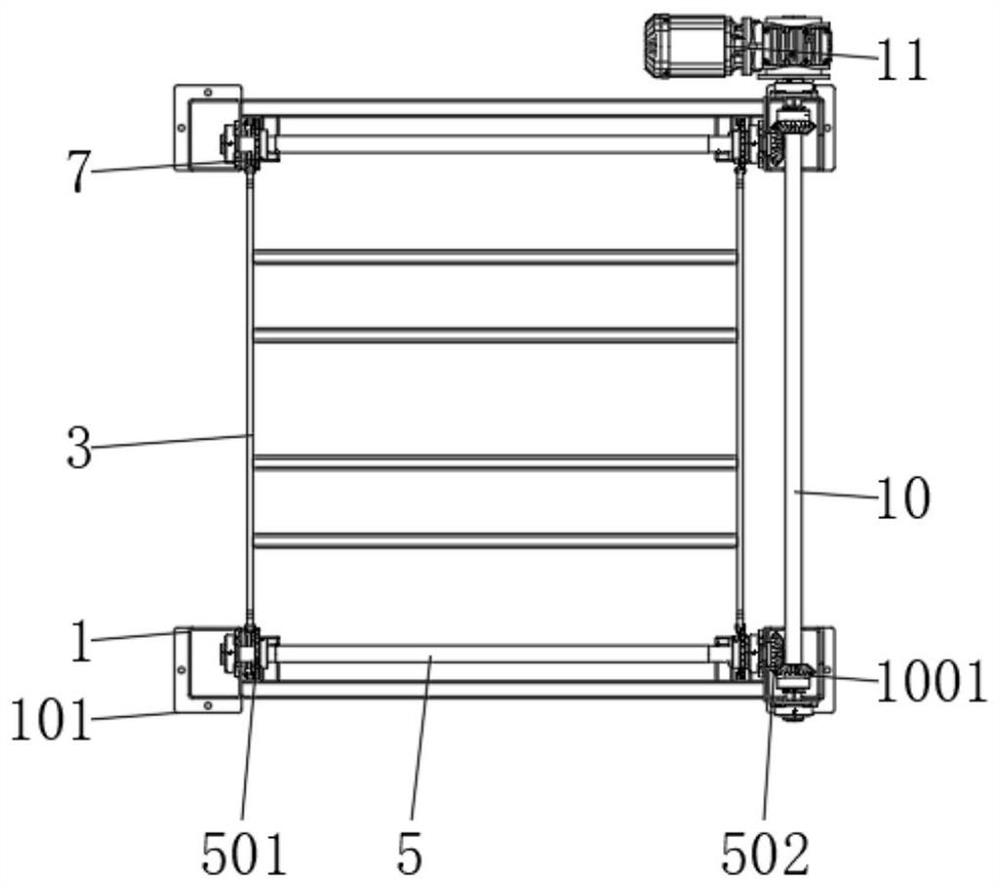

[0020] refer to Figure 1-4 , a lifting mechanism for tropical fruit processing, including a support frame 1 and a transmission frame 9, the front side and the rear side above the inside of the support frame 1 are installed with a rotating shaft 5 by inlaying and rotating, and the two sides of the rotating shaft 5 are All are fixed with rotating gear 501 by bolts, and the front side and the rear side of the inner bottom of the support frame 1 are fixed with wheel frame 701 by bolts, and the inside of wheel frame 701 is installed with follower gear 7 through the rotation of the rotating shaft. 501 and the outside of the follower gear 7 are equipped with a transmission...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap