Method for printing porous biological ceramic bone tissue engineering scaffold by utilizing sacrificial material

A technology of bone tissue engineering and bioceramics, applied in the direction of additive processing, ceramic products, applications, etc., can solve the problems of smaller and closed side holes, and achieve the effect of ensuring accurate printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to a method for printing porous bioceramic bone tissue engineering scaffolds using sacrificial materials, which includes the following steps:

[0033] S1: Build a 3D printing model: Obtain 3D printing models of bone tissue engineering scaffolds with different pore structures through 3D printing technology, and plan the printing path according to the 3D printing models;

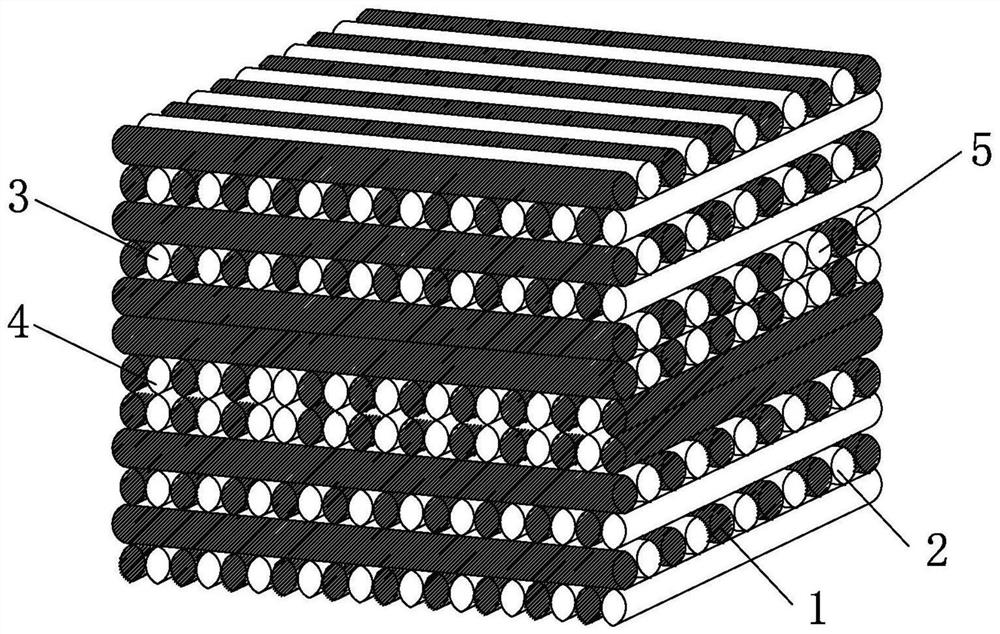

[0034] S2: At room temperature (20-30°C), print bone tissue engineering scaffolds layer by layer according to the printing path: use dual nozzles to print synchronously and coordinately, one nozzle ejects filamentous bioceramic material 1, and the other nozzle sprays the filamentous bioceramic material 1 on the adjacent filamentous The support material 2 is ejected between the bioceramic materials 1;

[0035] The support material 2 is a 3D printing ink prepared from an amphiphilic block copolymer. The amphiphilic block copolymer is Pluronic F127. Ronick F127 was dissolved in ice...

Embodiment 2

[0044] The method for printing porous bioceramic bone tissue engineering scaffolds using sacrificial materials in this embodiment is the same as that described in Embodiment 1, and will not be described in this embodiment.

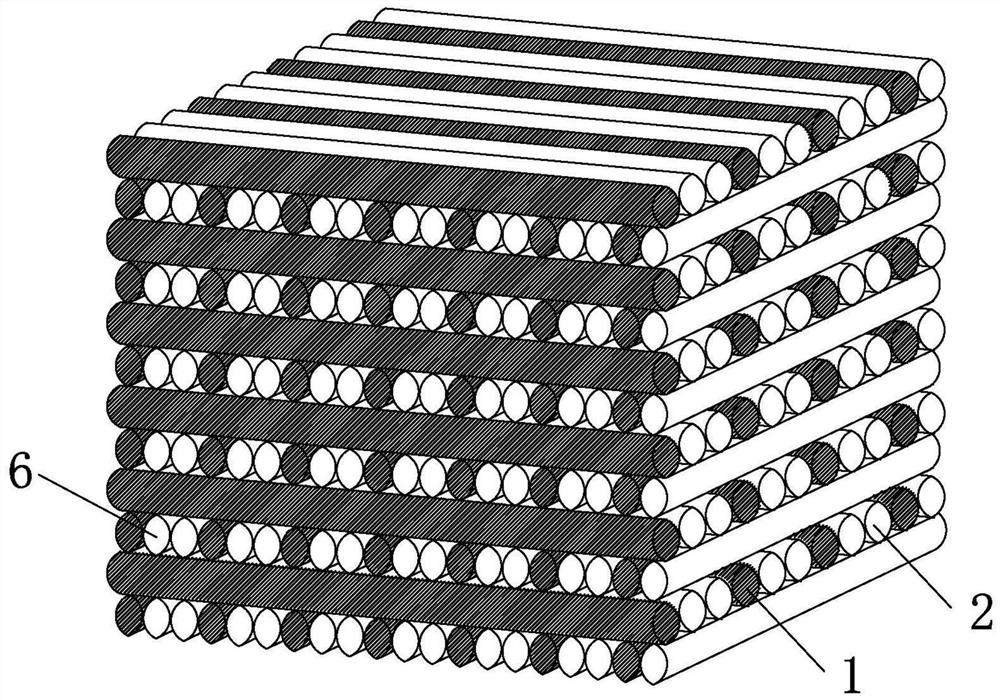

[0045] Refer to attached figure 2As mentioned above, in this embodiment, a total of 12 layers of porous bioceramic bone tissue engineering scaffolds are arranged, and the structure of each layer of porous bioceramic bone tissue engineering scaffolds is the same, 1 bioceramic materials are arranged at intervals, and 2 layers are arranged between adjacent bioceramic materials 1. Root support material 2, layer by layer 90° reverse (the angle of reverse can be set according to the construction of the 3D printing model, this embodiment only illustrates the situation of layer by layer 90° reverse, of course the angle of layer by layer can also be 45° , 60°, etc.), forming a lateral side hole 6.

[0046] Comparing this embodiment with the first embodiment, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com