Sewing equipment and connecting piece thereof

A technology for connectors and equipment, which is applied in the direction of sewing machine components, sewing equipment, sewing machine hooks, etc., can solve problems such as poor flexibility, high control complexity, and slow feedback speed, and achieve simple control, good flexibility, and avoid interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

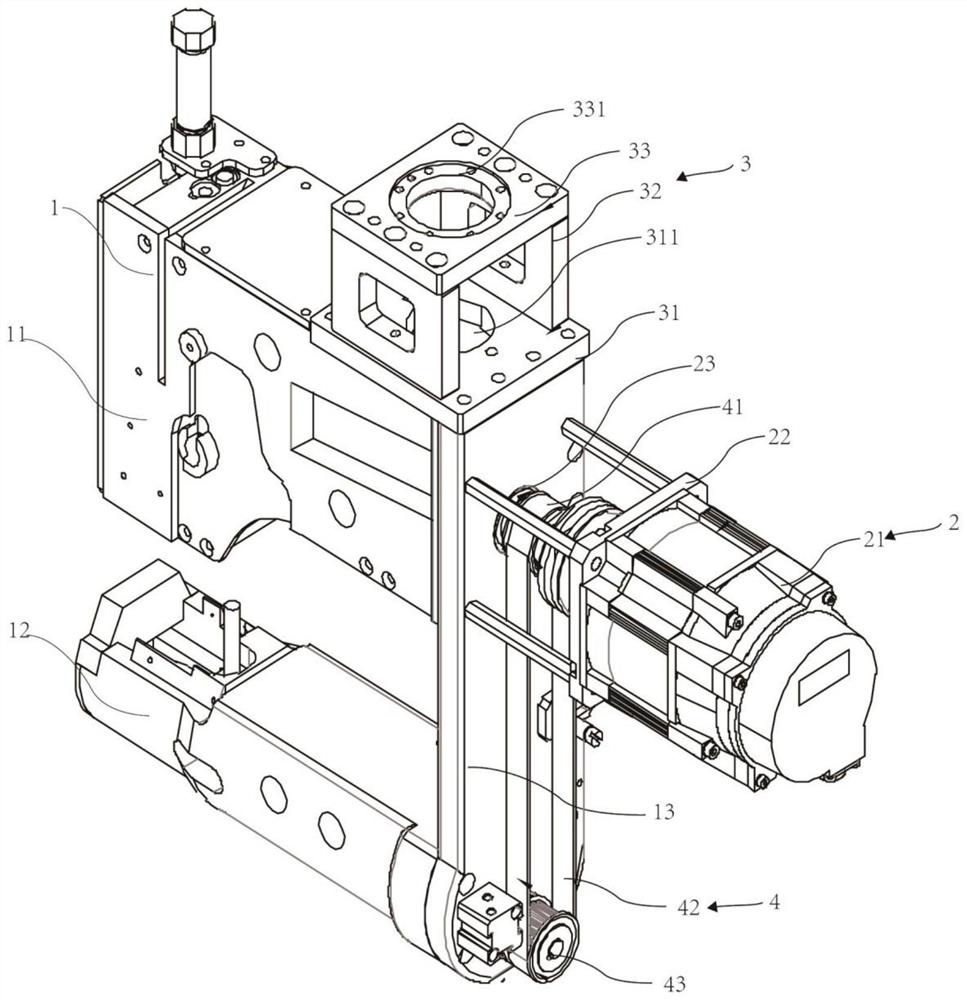

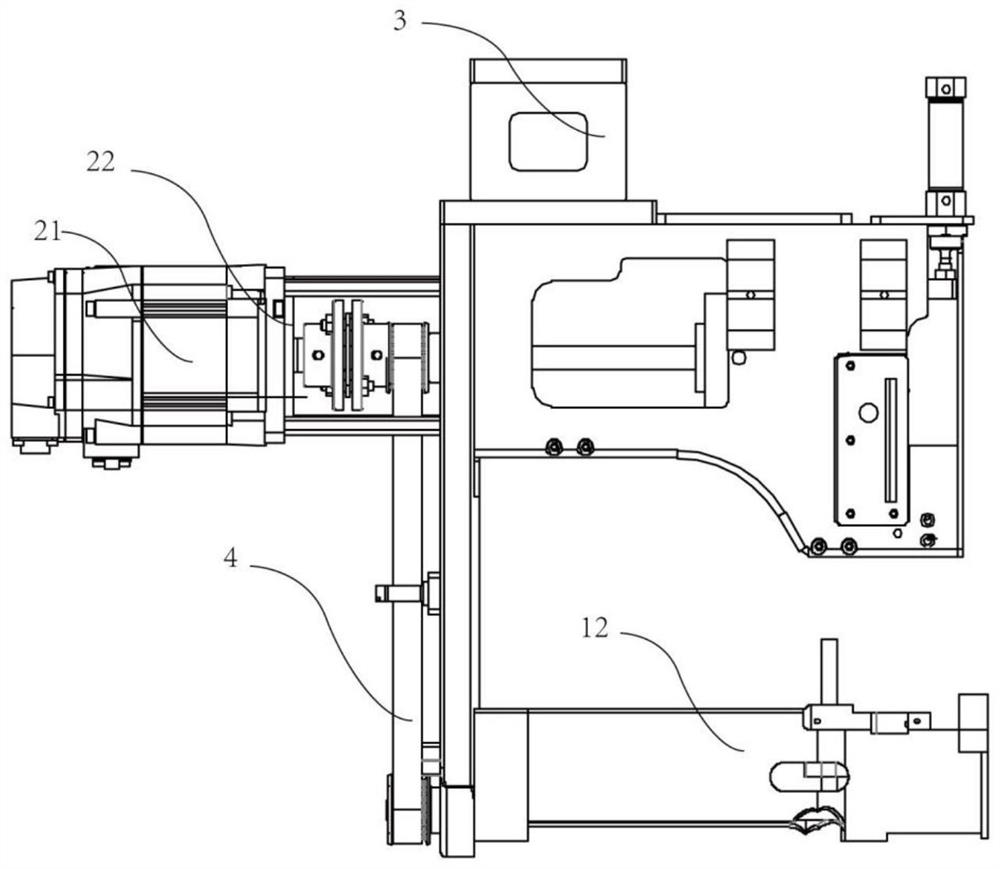

[0072] The present application will be described in detail below in conjunction with the accompanying drawings.

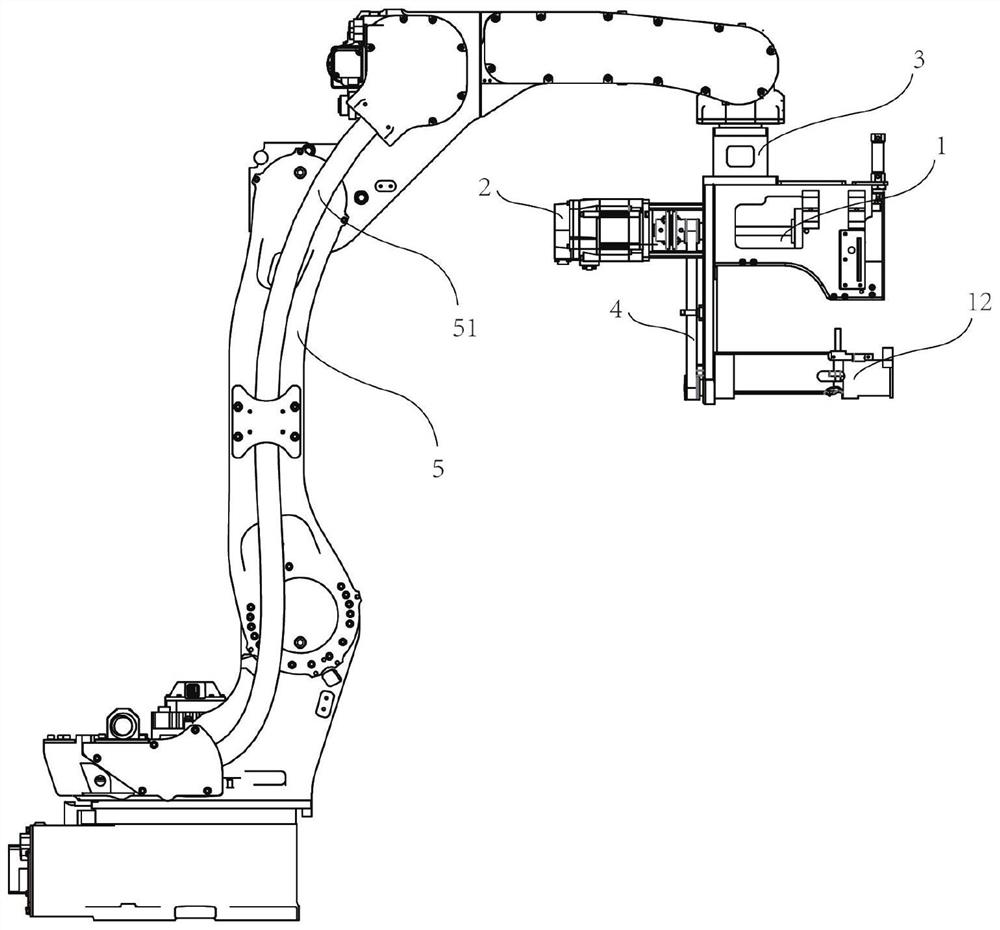

[0073] The inventors of the present application found that the problems of high control complexity, poor flexibility, and slow feedback speed can be solved by using a mechanical arm instead of a complex guide rail structure. However, the introduction of robotic arms creates new problems.

[0074] Generally speaking, the devices driven by the mechanical arm do not perform complex movements, such as spray guns, clamps and other devices, which generally only have two actions of "open" and "close". The range and scope are not large. Therefore, in the prior art, if the control of these devices is to be realized, the control wiring harness with certain elasticity is often directly connected to these devices, that is to say, it can be routed directly outside the mechanical arm.

[0075] However, for a sewing machine, many moving components such as sewing needles, transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com