Electronic thickness gauge for laser application

An electronic thickness gauge and laser technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of inaccurate measurement, inconvenient detection of the object to be measured, inconvenient practical use, etc., and achieve the effect of avoiding movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

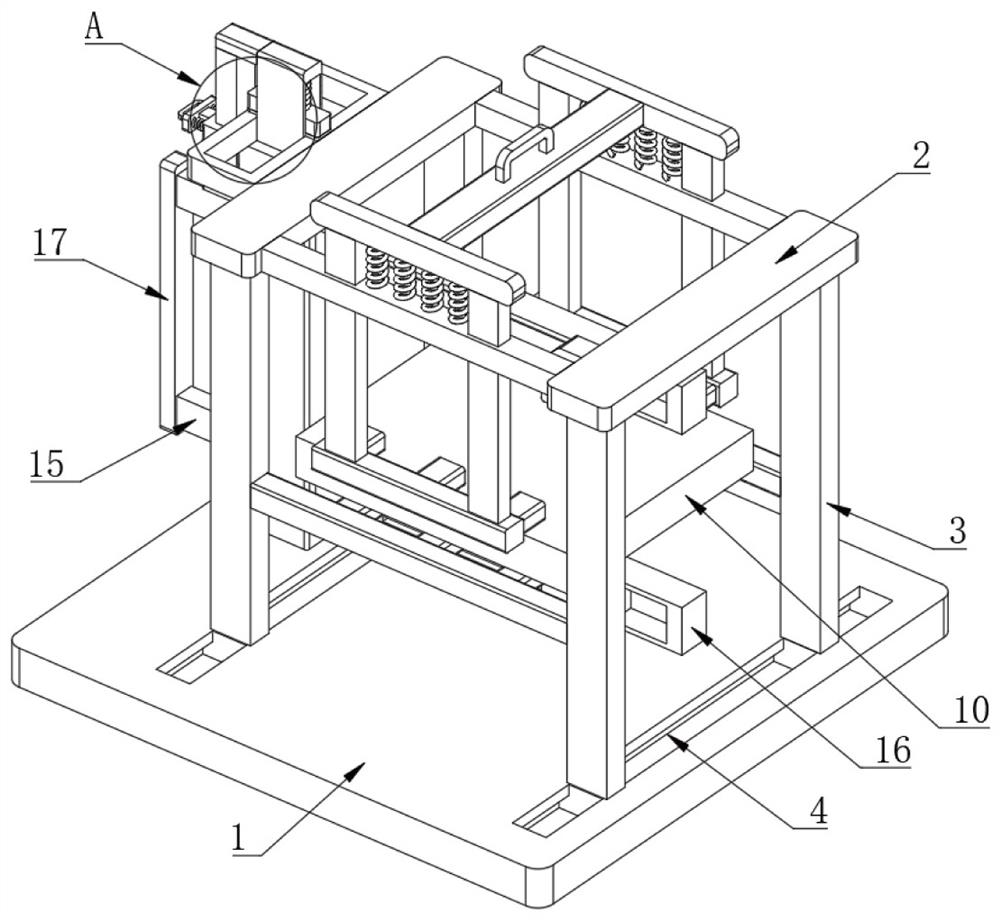

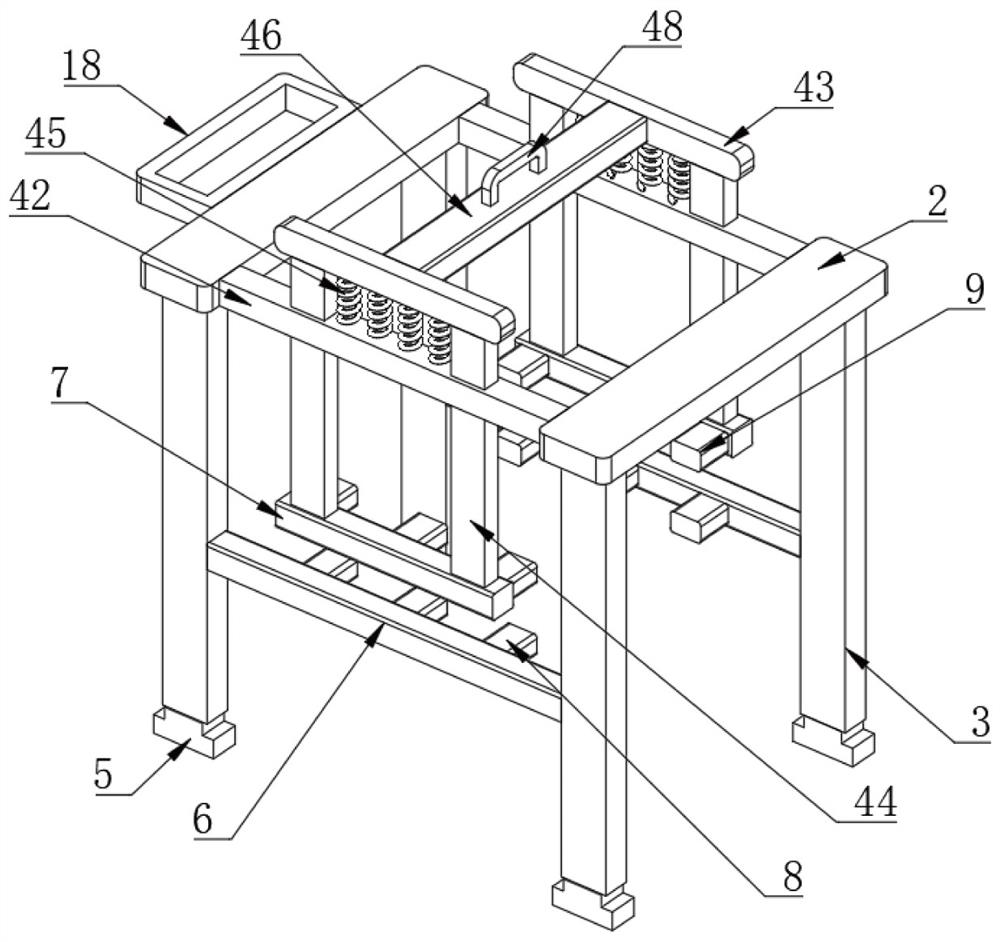

[0031] Such as Figure 1 to Figure 8 As shown, an electronic thickness gauge for laser application includes a base 1, two top plates 2 are arranged above the base 1, one side of one top plate 2 is fixedly connected with a first fixing ring 18, and the bottom of the top plate 2 is fixedly connected There are two first fixed columns 3, the bottom of the first fixed column 3 is fixedly connected with the first slider 5, the top of the base 1 is provided with two first slide grooves 4, and the top of the base 1 is provided with two first supports plate 6, the two ends of the first support plate 6 are respectively connected with the two first fixed columns 3, the object to be measured 10 is provided above the base 1, the first movable plate 7 is provided above the first support plate 6, and the first One side of the support plate 6 is fixedly connected with a plurality of supporting plates 8, and one side of the first movable plate 7 is fixedly connected with a plurality of first p...

Embodiment 2

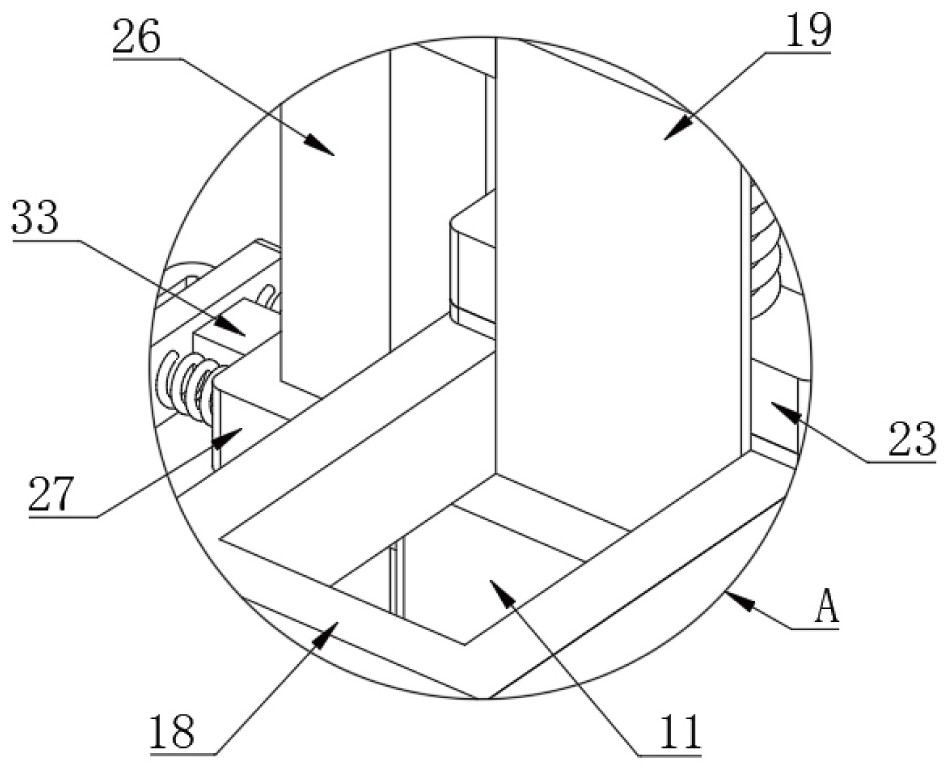

[0035] see Figure 1 to Figure 8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to figure 1 , image 3 , Figure 6 and Figure 8 , the fixed assembly includes a second connecting plate 25 arranged on one side of the lifting plate 19, the bottom of the second connecting plate 25 is fixedly connected with a second movable plate 26, and the second movable plate 26 is sheathed with a second fixed ring 27, One side of the second fixed ring 27 is fixedly connected with the first fixed plate 11, and the third fixed plate 28 is provided under the second movable plate 26, and one side of the third fixed plate 28 is fixedly connected with the first fixed plate 11, and the second fixed plate 28 is fixedly connected with the first fixe...

Embodiment 3

[0037] see Figure 1 to Figure 8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 3 and embodiment 1 is: please refer to Figure 6 and Figure 7 , the first elastic unit includes two second fixed columns 36 arranged in the second rectangular hole 22, both ends of the second fixed column 36 are fixedly connected with the inner wall of the second rectangular hole 22, and the outside of the second fixed column 36 A second compression spring 37 is sheathed, and the second compression spring 37 is located on the top of the second pressing plate 23. The second elastic unit includes a groove 38 opened at the bottom of the lifting plate 19, and a third movable plate is arranged in the groove 38. 39, the bottom of the third movable plate 39 is fixedly connected with the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap