Leakage testing device and leakage checking method

An equipment and leak testing technology, which is applied in the direction of detecting the appearance of fluid at the leak point, measuring device, fluid tightness test, etc. Detection and other issues, to achieve significant effects, improve operability and convenience, improve production efficiency and the quality of finished boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

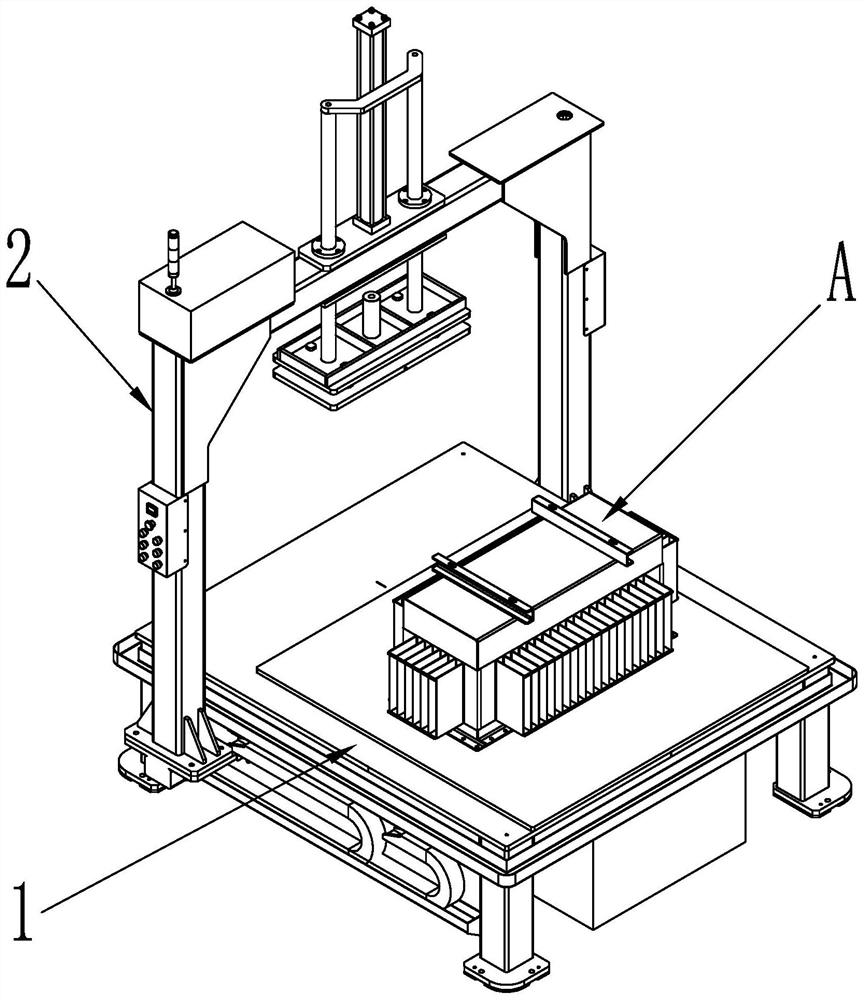

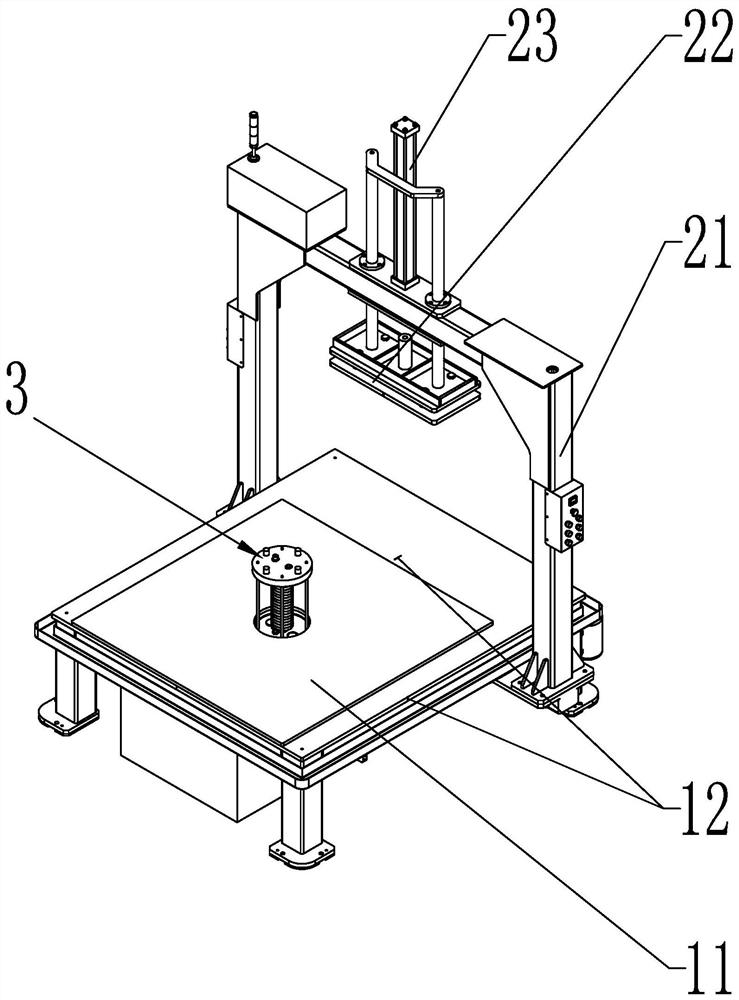

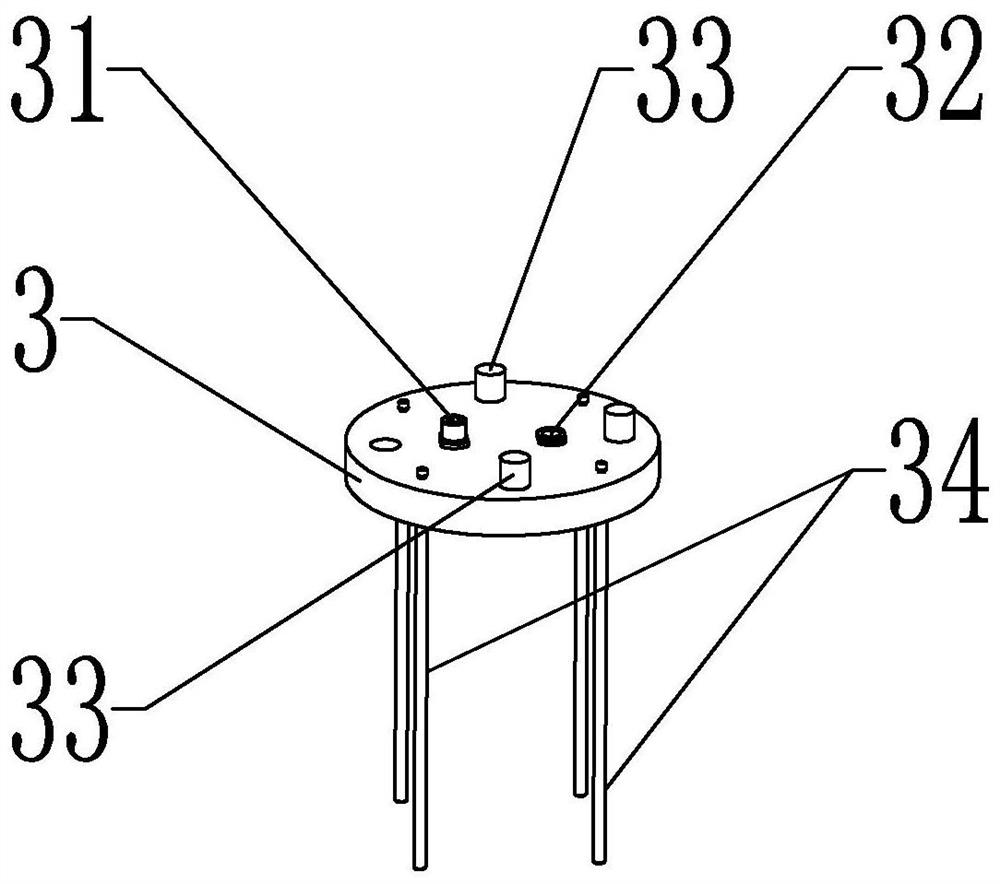

[0044] combine Figure 1 to Figure 7 , the present embodiment provides a leak testing device, which is suitable for the air tightness test of the box A of the transformer, and can specifically detect air leaks and water leaks. The leak testing equipment includes: a platform 1, a stand mechanism 2 and a floating mechanism.

[0045] The platform 1 is laid with a gasket 11, and the gasket 11 is preferably made of soft rubber. The platform 1 is correspondingly provided with a marking scale 12 that can indicate the position of the box A placed on the gasket 11 and guide it to be centered. The outer box A can be placed on the gasket 11 in an inverted manner and centered. .

[0046] The stand mechanism 2 includes a frame body 21 slidably arranged on the platform 1 , and a pressing member 22 and a driving member 23 arranged on the frame body 21 . The driving part 23 is connected with the pressing part 22 to drive the pressing part 22 to move up and down along the direction of press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com