A method and system for intelligent prediction of faults of filling and packaging machine

A technology of intelligent prediction and packaging machine, applied in the direction of instruments, geometric CAD, design optimization/simulation, etc., can solve the problem of inaccurate feature extraction, etc., and achieve the effect of improving prediction effect, improving accuracy and realizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

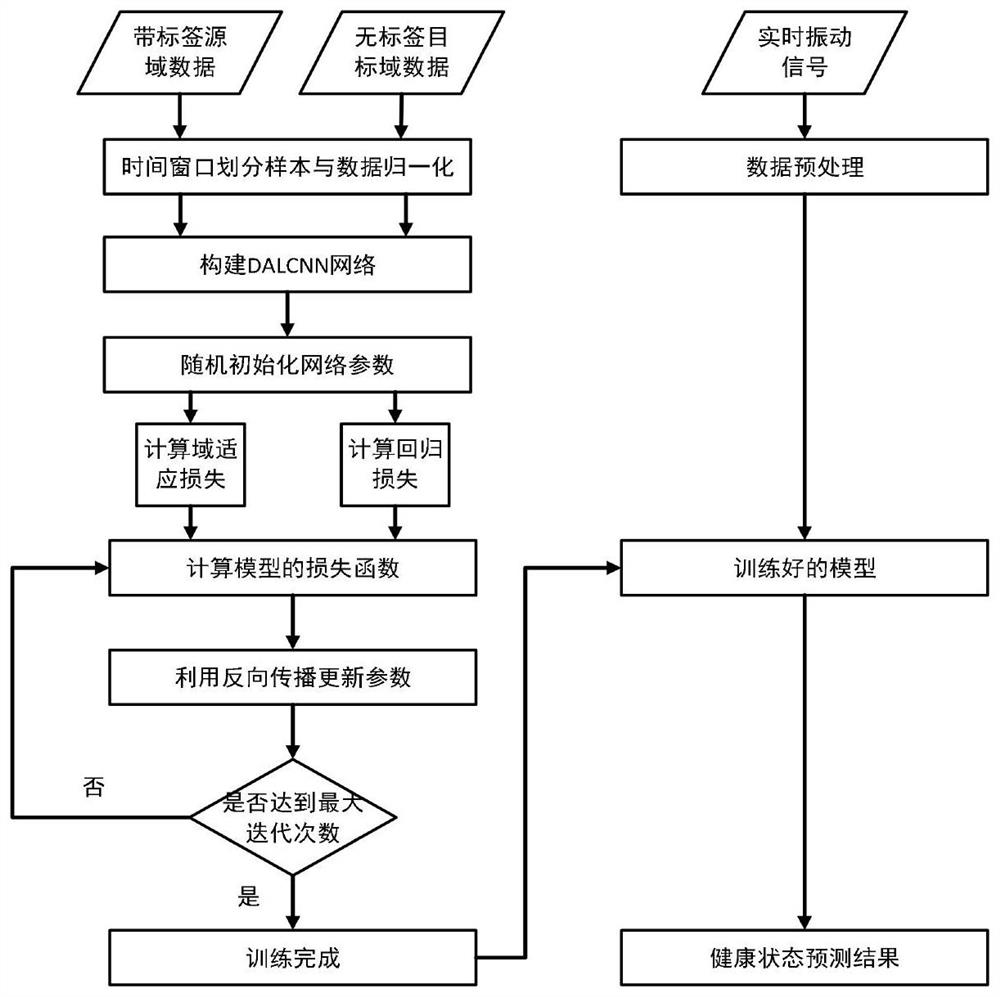

[0065] like figure 1 As shown, it is a preferred implementation process of a method for intelligently predicting faults of a filling and packaging machine according to the present invention. The method is a method for intelligently predicting faults of filling and packaging machines based on domain adaptation and deep learning, and includes the following steps:

[0066] Step S1, the collection of vibration signal: utilize the acceleration sensor to collect the vibration signal of the filling and packaging machine transmission system as the source domain vibration signal, and use the acceleration sensor to collect the vibration signal of the required monitoring filling and packaging machine transmission system as the target domain vibration signal;

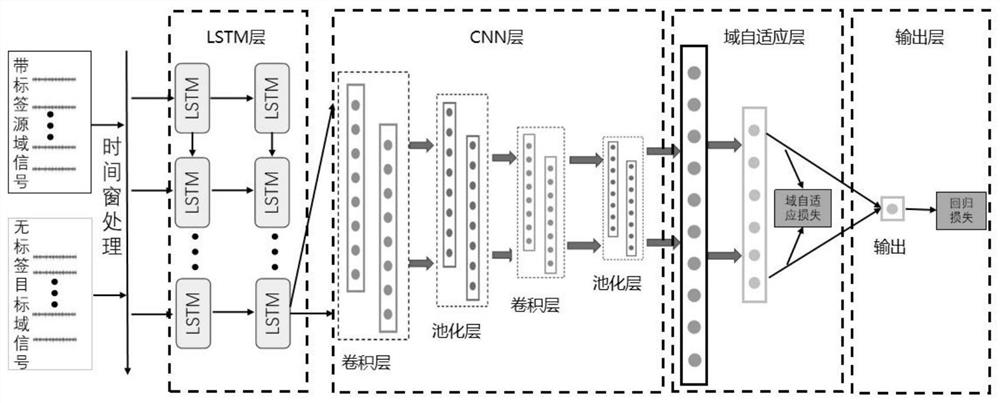

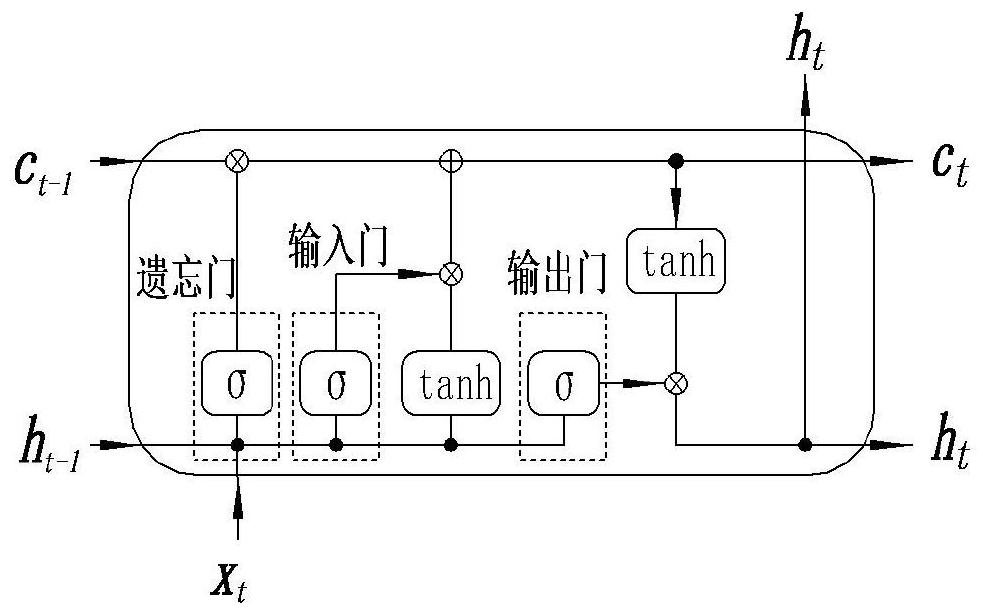

[0067] Step S2, the preprocessing of the vibration signal: the source domain vibration signal and its corresponding state label set use D s and y s Denotes that the target domain vibration signal and its corresponding state label ...

Embodiment 2

[0127] A system for an intelligent prediction method for faults of a filling and packaging machine, comprising a vibration signal acquisition module, a data division module, a training data preprocessing module, a model construction and training module and an online use module;

[0128] The vibration signal acquisition module is used to collect the source domain vibration signal and the target domain vibration signal of the transmission system of the filling and packaging machine;

[0129] The data division module is used to set the RUL label of the source domain data, and divide the training set and the test set;

[0130] The training data preprocessing module is used to divide the vibration signal into samples by using a sliding time window, and perform normalization processing;

[0131] The model construction and training module is used to construct a DALCNN model, and use the training data to train the network to obtain a fault prediction model capable of cross-domain proc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap